Zinc aluminum nickel tantalum alloy for hot plating and method of hot zinc plating

A nickel-tantalum alloy and zinc alloy technology, applied in the field of hot-dip galvanizing, can solve the problems of waste of zinc in the bottom slag, increase of iron particles in zinc alloy liquid, etc., achieve environmental friendliness, good high temperature oxidation resistance and corrosion resistance, and prevent the The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

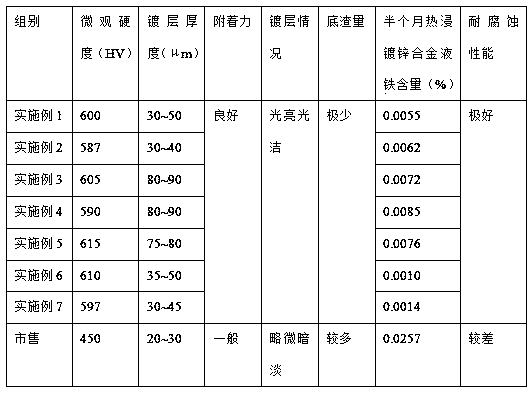

Examples

Embodiment 1

[0025] A zinc-aluminum-nickel-tantalum alloy S1 for hot-dip galvanizing is composed of 8wt% Al, 0.1wt% Ni, 0.05wt% Ta, and the balance is Zn and inevitable impurities brought by the zinc alloy.

[0026] The inorganic additive is composed of the following raw materials in parts by weight: 2 parts of ammonium chloride, 3 parts of nano-zirconia, 1 part of nano-magnesium oxide, 5 parts of quartz sand, 0.1 part of lanthanum nitrate, 0.1 part of cerium nitrate, and 1 part of sodium molybdate and 0.1 part of europium nitrate.

[0027]An inorganic additive was added to the molten zinc-aluminum-nickel-tantalum alloy S1 alloy solution for hot-dip galvanizing of the present embodiment, and the addition amount of the inorganic additive was 0.05 g / kg. After stirring evenly, the temperature of the alloy solution was 585° C., and the steel pipe was hot-dipped for 1.5 minutes, and the thickness of the formed coating was uniform.

Embodiment 2

[0029] A zinc-aluminum-nickel-tantalum alloy S2 for hot-dip galvanizing is composed of 20wt% Al, 0.5wt% Ni, 0.1wt% Ta, and the balance is Zn and inevitable impurities brought by the zinc alloy.

[0030] The inorganic additive is composed of the following raw materials by weight: 5 parts of ammonium chloride, 5 parts of nano-zirconia, 3 parts of nano-magnesium oxide, 10 parts of quartz sand, 0.5 parts of lanthanum nitrate, 0.2 parts of cerium nitrate, and 2 parts of sodium molybdate and 0.3 parts of europium nitrate.

[0031] An inorganic additive was added to the molten zinc-aluminum-nickel-tantalum alloy S2 alloy solution for hot-dip galvanizing of the present embodiment, and the addition amount of the inorganic additive was 0.01 g / kg. After stirring evenly, the temperature of the alloy solution was 575° C., and the strip was hot-dipped for 15 seconds, and the thickness of the formed coating was uniform.

Embodiment 3

[0033] A zinc-aluminum-nickel-tantalum alloy S3 for hot-dip galvanizing is composed of 0.1wt% Al, 0.2wt% Ni, 0.1wt% Ta, and the balance is unavoidable impurities brought by Zn and the zinc alloy.

[0034] The inorganic additive is composed of the following raw materials in parts by weight: 3 parts of ammonium chloride, 4 parts of nano-zirconia, 2 parts of nano-magnesium oxide, 6 parts of quartz sand, 0.2 parts of lanthanum nitrate, 0.12 parts of cerium nitrate, and 1.2 parts of sodium molybdate and 0.15 parts of europium nitrate.

[0035] An inorganic additive was added to the molten zinc-aluminum-nickel-tantalum alloy S3 alloy solution for hot-dip galvanizing of the present embodiment, and the addition amount of the inorganic additive was 0.02 g / kg. After stirring evenly, the temperature of the alloy liquid was 570° C., and the high-silicon and high-manganese steel large-tube tower pieces with discs at both ends were hot-dipped for 3 minutes, and the thickness of the formed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap