Medium-high temperature oxidation resistant Ti/TiN multilayer coating and preparation method

A multi-layer coating, medium and high temperature technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve problems such as cracking and peeling, achieve low preparation cost, improve bonding strength, internal stress buffering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

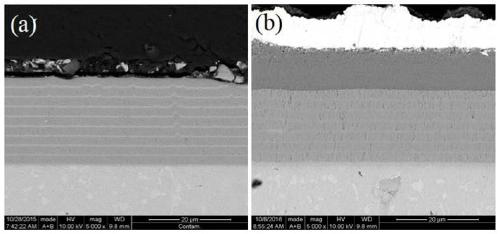

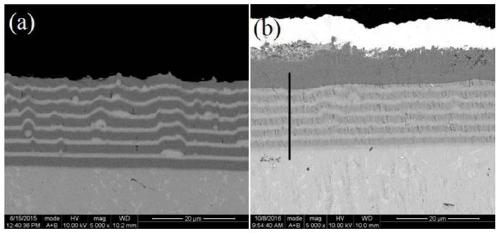

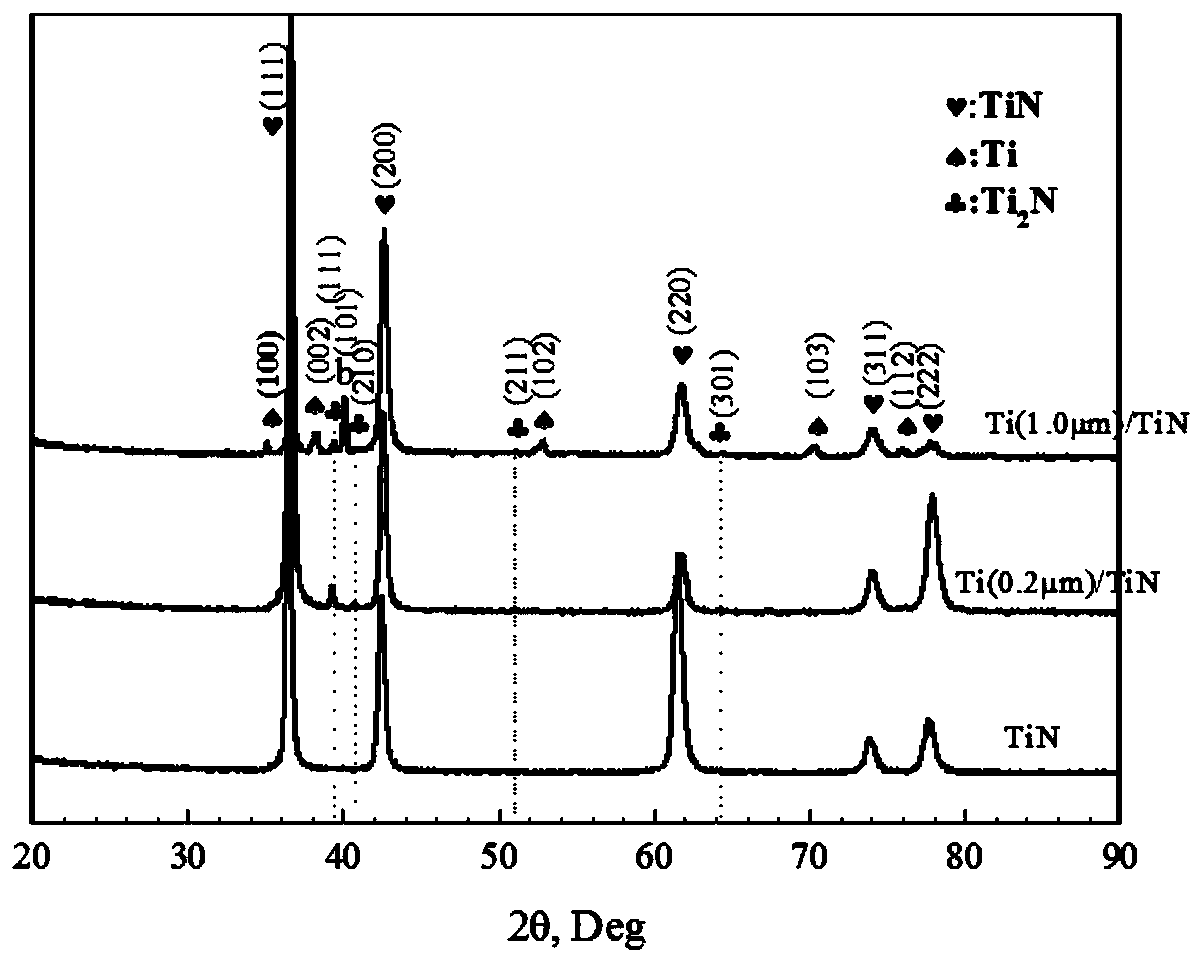

[0049] In this embodiment, the preparation method of the Ti / TiN multilayer coating resistant to medium and high temperature oxidation comprises the following steps:

[0050] (1) Pretreatment

[0051] TC4 titanium alloy is selected, the sample size is 10mm×10mm×2mm, the surface is polished to remove surface oil and rust, and then placed in acetone and ethanol solutions in turn, and ultrasonic cleaning is performed for 5 minutes each to further remove oil and other attachments on the surface of the substrate. After fully drying with a hair dryer, quickly hang it on the sample rack, put it into the studio and vacuumize it to 6.0×10 -3 Pa.

[0052] (2) Ion cleaning

[0053] The argon gas was introduced, the pressure was controlled at 0.2 Pa, the negative bias value of 800V was applied to the substrate, the duty ratio was 20%, and the ion bombardment cleaning time was 10 minutes.

[0054] (3) Deposition of sub-layers

[0055] After ion cleaning, cut off the argon gas, feed in n...

Embodiment 2

[0058] In this embodiment, the preparation method of the Ti / TiN multilayer coating resistant to medium and high temperature oxidation comprises the following steps:

[0059] (1) Pretreatment

[0060] TC4 titanium alloy is selected, the sample size is 10mm×15mm×2mm, the surface is polished to remove surface oil and rust, and then placed in acetone and ethanol solutions in turn, and ultrasonic cleaning is performed for 7 minutes each to further remove oil and other attachments on the surface of the substrate. After fully drying with a hair dryer, quickly hang it on the sample rack, put it into the working room and evacuate it to 6.5×10 -3 Pa.

[0061] (2) Ion cleaning

[0062] The argon gas was introduced, the pressure was controlled at 0.25 Pa, the negative bias value of 850 V was applied to the substrate, the duty ratio was 25%, and the ion bombardment cleaning time was 13 minutes.

[0063] (3) Deposition of sub-layers

Embodiment 3

[0067] In this embodiment, the preparation method of the Ti / TiN multilayer coating resistant to medium and high temperature oxidation comprises the following steps:

[0068] (1) Pretreatment

[0069] TA11 titanium alloy is selected, the sample size is 15mm×15mm×1mm, the surface is polished to remove surface oil and rust, and then placed in acetone and ethanol solutions in turn, and ultrasonic cleaning is performed for 10 minutes each to further remove oil and other attachments on the surface of the substrate. After fully drying with a hair dryer, quickly hang it on the sample rack, put it into the studio and vacuumize it to 7.0×10 -3 Pa.

[0070] (2) Ion cleaning

[0071] Argon gas was introduced, the pressure was controlled at 0.3 Pa, a negative bias voltage of 900V was applied to the substrate, the duty cycle was 20%, and the ion bombardment cleaning time was 15 minutes.

[0072] (3) Deposition of sub-layers

[0073] After ion cleaning, cut off the argon gas, feed in nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com