Chromium, aluminum, silicon and nickel quarternary alloy target material and preparation method thereof

A quaternary alloy target, silicon-nickel technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem that the uniformity of composition and structure in the alloy is difficult to guarantee, and it is difficult to obtain high-quality and high-density targets. It is suitable for large-scale industrial production and application, with many specifications and small grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

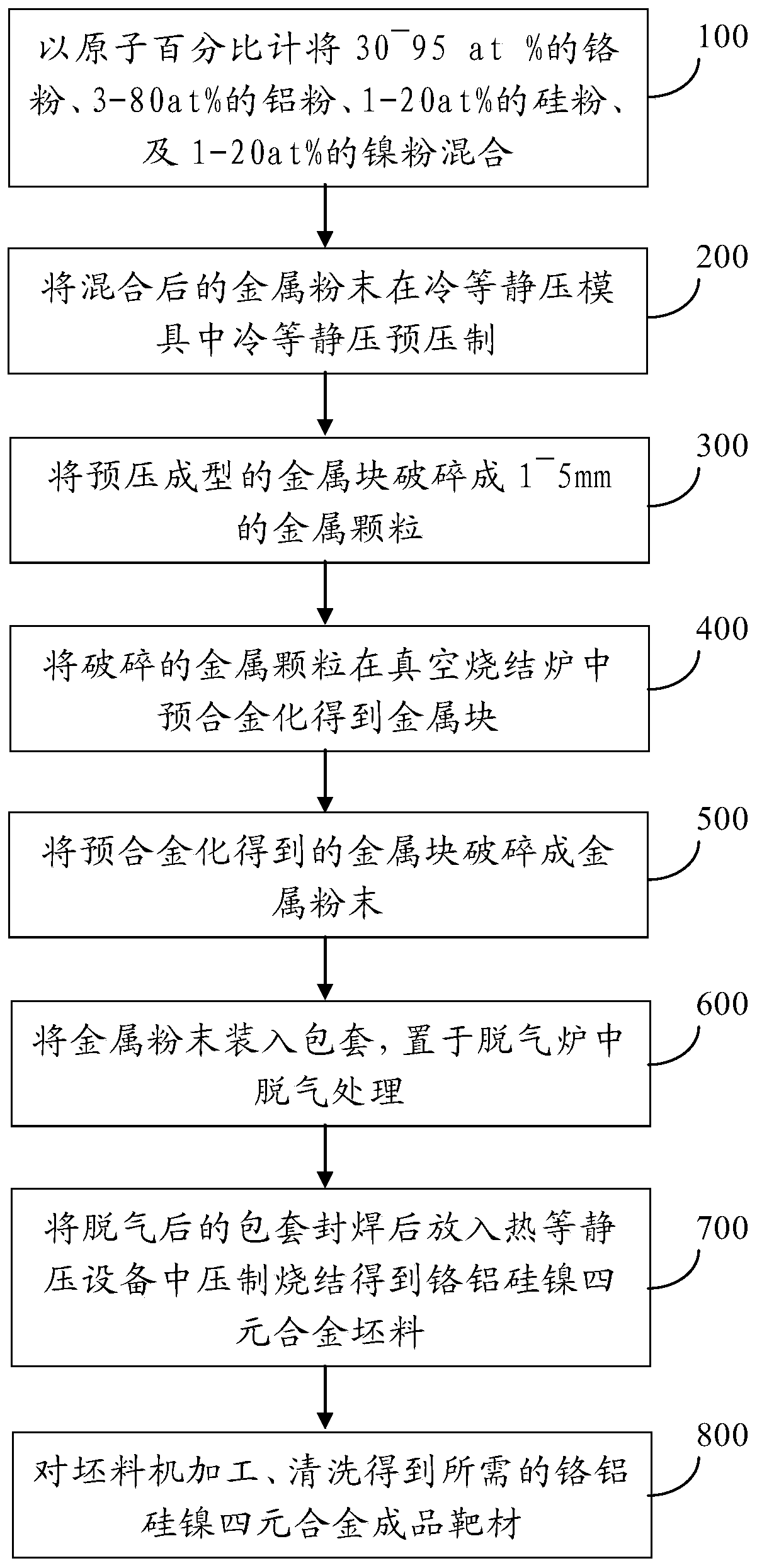

[0028] see figure 1 , a method for preparing a chromium-aluminum-silicon-nickel quaternary alloy target provided by an embodiment of the present invention includes the following steps:

[0029] Step 100: In atomic percentage, mix 30-95at% chromium powder, 3-80at% aluminum powder, 1-20at% silicon powder, and 1-20at% nickel powder;

[0030] Step 200: Cold isostatic pre-pressing the mixed metal powder in a cold isostatic pressing mold;

[0031] Step 300: breaking the pre-pressed metal block into 1-5mm metal particles;

[0032] Step 400: pre-alloying the broken metal particles in a vacuum sintering furnace to obtain an alloy block;

[0033] Step 500: breaking the alloy block obtained by pre-alloying into alloy powder;

[0034] Step 600: Put the alloy powder into a bag, and place it in a degassing furnace for degassing;

[0035] Step 700: sealing and welding the degassed sheath and putting it into a hot isostatic pressing device for pressing and sintering to obtain the chromium...

example 1

[0047] The chromium-aluminum-silicon-nickel alloy target of the present invention is made of the following atomic percentages of raw materials: 91% chromium, 3% aluminum, 3% silicon, and 3% nickel; the preparation method of the chromium-aluminum-silicon-nickel target in this example includes the following steps :

[0048] (1) Weigh chromium powder and nickel powder with a purity of 99.5%, an average particle size of 75 μm, an average particle size of 63 um aluminum powder, and an average particle size of 45 um, and mix them in a three-dimensional mixer for 3 hours. The medium is filled with high-purity argon for protection;

[0049] (2) Pack the mixed powder into the cold isostatic pressing forming mold and carry out cold isostatic pressing pre-compression, the cold isostatic pressing pressure is 100MPa, and the holding pressure is 10 minutes;

[0050] (3) Use jaw crushing equipment to crush the cold isostatic pre-pressed compact, and the particle size of the crushed particle...

example 2

[0058] The chromium-aluminum-silicon-nickel alloy target of the present invention is made of the raw materials with the following atomic percentages: 60% chromium, 22% aluminum, 10% silicon, and 8% nickel; the preparation method of the chromium-aluminum-silicon-nickel target in this example comprises the following steps :

[0059] (1) Take by weighing 99.5% purity, chromium powder and nickel powder with an average particle size of 100 μm, aluminum powder with an average particle size of 70 μm, and silicon powder with an average particle size of 45 μm, and mix them in a three-dimensional mixer for 3 hours. The medium is filled with high-purity argon for protection;

[0060] (2) Pack the mixed powder into the cold isostatic pressing forming mold and carry out cold isostatic pressing pre-compression, the cold isostatic pressing pressure is 80MPa, and the holding pressure is 10 minutes;

[0061] (3) The cold isostatic pre-pressed compact is crushed with jaw crushing equipment, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com