Preparation method of magnesium-enriched biochar for synchronously and efficiently recycling nitrogen and phosphorus nutrients in farm waste liquid and application of magnesium-enriched biochar

A technology for farms and biochar, applied in chemical instruments and methods, applications, waste fuels, etc., can solve the problems of few effective utilization methods, low comprehensive utilization efficiency, waste of resources and the environment, and achieve the improvement of plant rhizosphere environment, water Pollution control is extensive and the effect of promoting straw transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

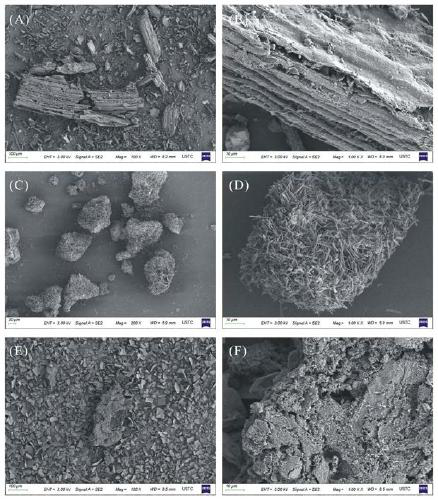

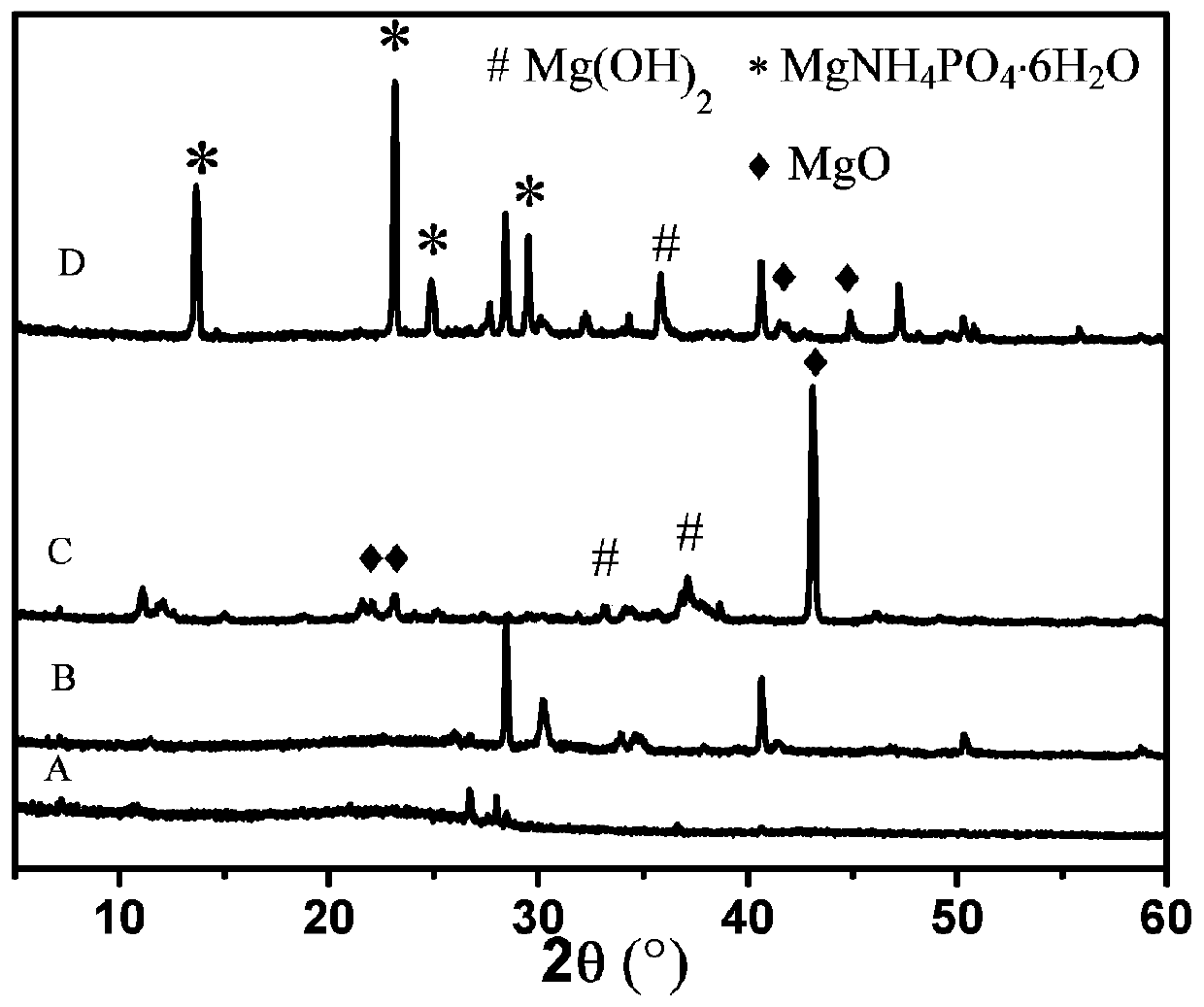

[0028] The preparation method of magnesium-rich biochar for synchronously and efficiently recovering nitrogen and phosphorus nutrients in farm waste liquid of the present invention includes the following steps: (1) Adding biomass powder to magnesium chloride solution and mixing thoroughly, and microwave after mixing. Processed to obtain a magnesium chloride solution in which biomass is dispersed;

[0029] (2) Then the above solution is stirred for a certain period of time, filtered and dried to obtain magnesium-rich biomass; finally, the magnesium-rich biomass is transferred to an anoxic atmosphere and thermally cracked at a temperature of 450-700℃ to obtain synchronous high efficiency Magnesium-rich biochar that recycles nitrogen and phosphorus nutrients in waste liquid from farms.

[0030] The magnesium-rich biochar is prepared by the preparation method of the present invention.

[0031] The application of the magnesium-rich biochar of the present invention in the synchronous reco...

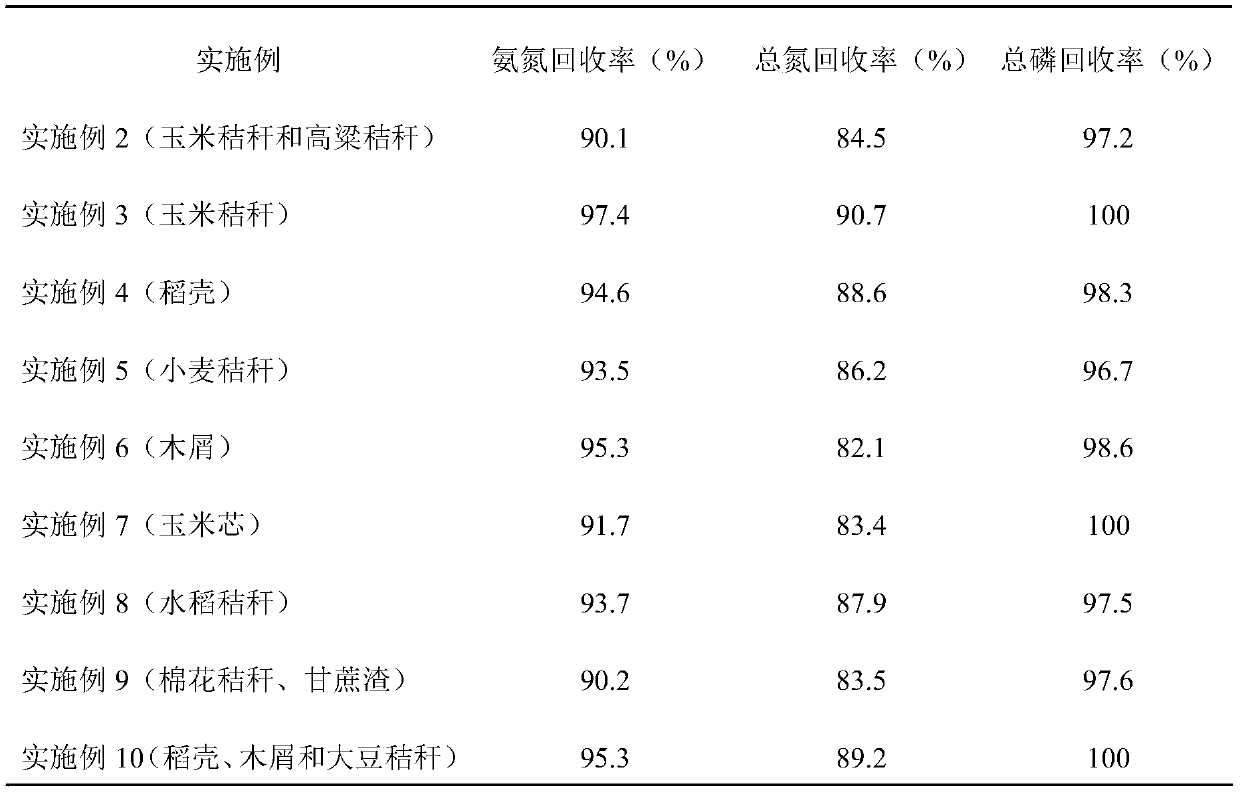

Embodiment 2

[0034] The difference between Example 2 and Example 1 is that in step (1), microwave-assisted impregnation: 9g of dry biomass powder is added to 100mL of magnesium chloride solution with a concentration of 1mol / L, mixed thoroughly and placed in a microwave environment Treat for 30 minutes, and continue magnetic stirring at 500 rpm for 8 hours to obtain a biomass mixed solution fully impregnated with magnesium chloride;

[0035] The lignocellulosic biomass powder is a sieved powder obtained by drying the lignocellulosic biomass at 60-105°C, pulverizing, and passing through a 100-mesh sieve. The lignocellulosic biomass is a combination of corn stover and sorghum stover. The 1mol / L magnesium chloride solution is MgCl 2 ·6H 2 O is made by dissolving in water. The microwave frequency in the microwave environment is 2.45 GHz, and the microwave power is 100 W.

[0036] In step (2), thermal cracking: filter the biomass solution fully impregnated with magnesium chloride obtained in step (...

Embodiment 3

[0038] Preparation of Magnesium-rich Biochar from Corn Stalks

[0039] The preparation method of magnesium-rich biochar for synchronously and efficiently recovering nitrogen and phosphorus nutrients in waste liquid from farms of the present invention includes the following steps: in step (1), microwave-assisted soaking: collecting corn in the experimental field of Anhui Agricultural University The straw is washed and dried at 90° C. and crushed. After crushing, it is passed through a 100-mesh sieve and the sieved corn stalk powder is collected. Take 6g corn stover powder and add it to 100mL 1.5mol / L MgCl 2 In the solution, mix well and treat for 20 minutes in a microwave environment with a power of 100W, and continue to magnetically stir at 300 rpm for 4 hours to obtain MgCl dispersed with corn stover powder 2 Solution. The microwave frequency in the microwave environment is 2.45 GHz, and the microwave power is 800 W.

[0040] In step (2), thermal cracking: filter the biomass solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com