Production method of graphene foam/magnetic nanowire composite wave-absorbing material

A composite absorbing material, graphene foam technology, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of poor absorbing performance, complex preparation methods, large specific surface area, etc., to achieve good toughness, good electricity The effect of chemical activity and good absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

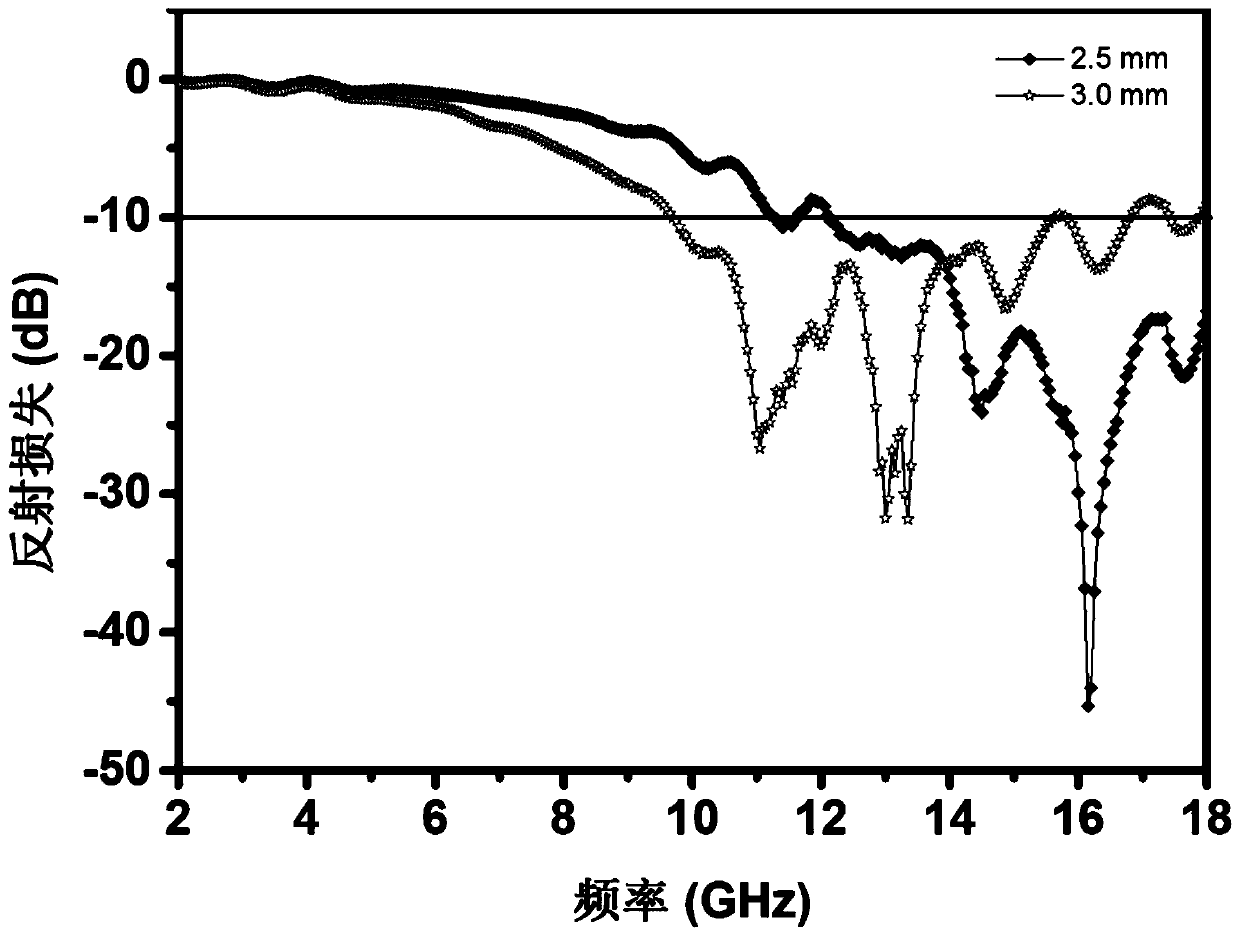

Image

Examples

preparation example Construction

[0028] A preparation method of a graphene foam / magnetic nanowire composite wave-absorbing material, the specific steps are as follows:

[0029] (1) Preparation of graphene oxide aqueous solution: Weigh 35ml, 2-5mg / ml graphene oxide in beaker A, weigh 10-100ml deionized water with a measuring cylinder, pour it into beaker A, stir while injecting, Transfer to 50ml centrifuge tube B after forming a uniform graphene aqueous solution;

[0030] (2) Preparation of graphene oxide ethanol solution: Weigh 30-100ml ethanol solution with a measuring cylinder, pour it into centrifuge tube B, shake well, put it into a centrifuge for centrifugation, the speed is 10000-12000r / min, and the time is 2-10min, pour out about 30-100ml supernatant after centrifugation, stir the residue and then add 30-100ml ethanol solution for centrifugation, repeat this operation 6 times, measure 35-65ml ethanol as the solvent for oxidation Graphene solution;

[0031] (3) Preparation of graphene oxide foam: put ...

Embodiment 1

[0036] This embodiment is a preparation method of graphene foam / nickel cobaltate nanowires with wave-absorbing properties, which is carried out in the following steps:

[0037] (1) Preparation of graphene oxide aqueous solution: Weigh 35ml, 2.5mg / ml graphene oxide in beaker A, weigh 10ml of deionized water, inject it into beaker A, stir while injecting, and form a uniform graphene aqueous solution Transfer to 50ml centrifuge tube B;

[0038] (2) Preparation of graphene oxide ethanol solution: Weigh 30ml of ethanol solution with a measuring cylinder, pour it into centrifuge tube B, shake well, put it in a centrifuge for centrifugation, the speed is 11000r / min, the time is 2min, and the centrifugation is over Finally pour out about 30ml supernatant, stir the residue and then add 30ml ethanol solution for centrifugation, repeat the operation 6 times like this, measure 35ml ethanol as the graphene oxide solution of solvent;

[0039] (3) Preparation of graphene oxide foam: 35ml of...

Embodiment 2

[0045] This embodiment is a preparation method of graphene foam / cobalt tetroxide nanowires with wave-absorbing properties, which is carried out in the following steps:

[0046] (1) Preparation of graphene oxide aqueous solution: Weigh 35ml, 2.5mg / ml graphene oxide in beaker A, weigh 10ml of deionized water, inject it into beaker A, stir while injecting, and form a uniform graphene aqueous solution Transfer to 50ml centrifuge tube B;

[0047] (2) Preparation of graphene oxide ethanol solution: Weigh 30ml of ethanol solution with a measuring cylinder, pour it into centrifuge tube B, shake well, put it in a centrifuge for centrifugation, the speed is 11000r / min, the time is 2min, and the centrifugation is over Finally pour out about 30ml supernatant, stir the residue and then add 30ml ethanol solution for centrifugation, repeat the operation 6 times like this, measure 35ml ethanol as the graphene oxide solution of solvent;

[0048] (3) Preparation of graphene oxide foam: 35ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com