HIT solar cell recycling pretreatment method

A solar cell and pretreatment technology, applied in chemical instruments and methods, silicon compounds, silicon oxides, etc., can solve the problems of numerous impurities, rare metal indium recovered, affecting the recovery of indium, silver and silicon wafers, etc. The effect of reducing silver loss and waste, reducing demand burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

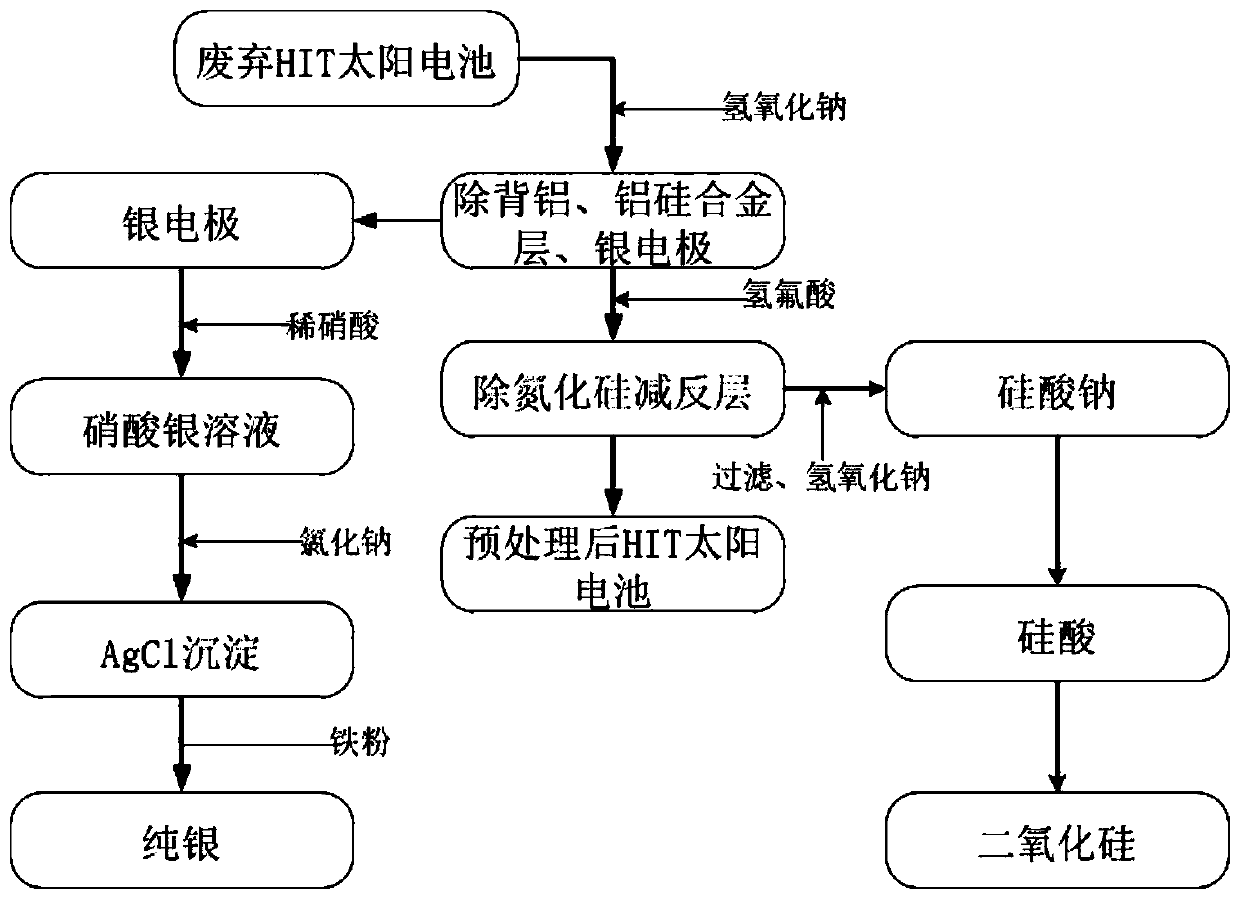

[0027] In order to realize the pretreatment of waste HIT solar cells, the present invention provides a method for pretreatment of HIT solar cells, see figure 1 , follow the steps below:

[0028] 1. HIT battery pretreatment

[0029] Select a piece of waste single-sided HIT solar cell, the size of the silicon cell is 155x155mm, and the flat angle is 15mm; the aluminum back plate is 157x157mm, and the flat angle is 13mm; the weight of the whole battery is 9.708g, and the overall thickness is about 200mm. It is cut and broken into larger sub-blocks by cutting machine.

[0030] Measure 90ml of deionized water with a measuring cylinder and pour it into a beaker, weigh 10g of caustic soda (sodium hydroxide) and add it to the beaker for mixing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com