Preparation method of self-assembled hydrophobic light-reflecting and light-converting material

A self-assembly and hydrophobic technology, which is applied in the field of preparation of self-assembled hydrophobic light-reflective and light-transforming materials, can solve the problems of short light-reflecting effect, no light-transforming function, poor aging resistance, etc., and achieves simple preparation methods and reduced labor costs. Strength and the effect of prolonging the life of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

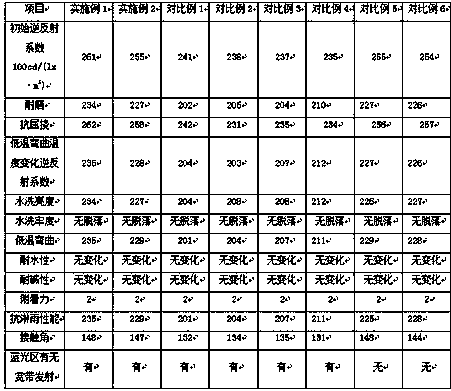

Examples

Embodiment 1

[0017]A preparation method of a self-assembled hydrophobic light-reflecting light-transforming material is characterized in that it comprises the following steps: 1. Dissolving salicylaldehyde benzoylhydrazone and acetylbenzenetosylhydrazone in tetramethylethylenediamine, adding n-Butyl lithium n-hexane solution, stir to mix the liquid evenly, and use this as an initiator in a microwave plasma generation processor with a radio frequency power supply, with 1-bromobutane, tetramethylsilane and carbon tetrafluoride 1:1:1 The mixed gas undergoes plasma grafting reaction, during which 600W is used for microwave radiation treatment, during which the polymer film material is placed between the two discharge electrodes of the dielectric barrier discharge, and the mass barrier discharge plasma graft polymerization is performed, and the polymer film The material is poly-4-methylpentene. The treated polymer film material is soaked in aluminum trichloride solution, then added buffer soluti...

Embodiment 2

[0025] A preparation method of a self-assembled hydrophobic light-reflecting light-transforming material is characterized in that it comprises the following steps: 1. Dissolving salicylaldehyde benzoylhydrazone and acetylbenzenetosylhydrazone in tetramethylethylenediamine, adding n-Butyl lithium n-hexane solution, stir to mix the liquid evenly, and use this as an initiator in a microwave plasma generation processor with a radio frequency power supply, with 1-bromobutane, tetramethylsilane and carbon tetrafluoride 1:1:1 The mixed gas undergoes plasma grafting reaction, during which 500W is used for microwave radiation treatment, during which the polymer film material is placed between the two discharge electrodes of dielectric barrier discharge, and mass barrier discharge plasma graft polymerization is carried out, and the polymer film The material is poly-4-methylpentene. The treated polymer film material is soaked in aluminum chloride solution, then added with buffer solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com