A long-term solid high-strength self-reinforcing submarine cable and its manufacturing method

A submarine cable, high-strength technology, applied in the direction of submarine cables, power cables, insulated cables, etc., can solve the problems of long production cycle, many riverbeds and roads, high manufacturing costs, and achieve well-preserved, good membrane self-bonding, and less impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

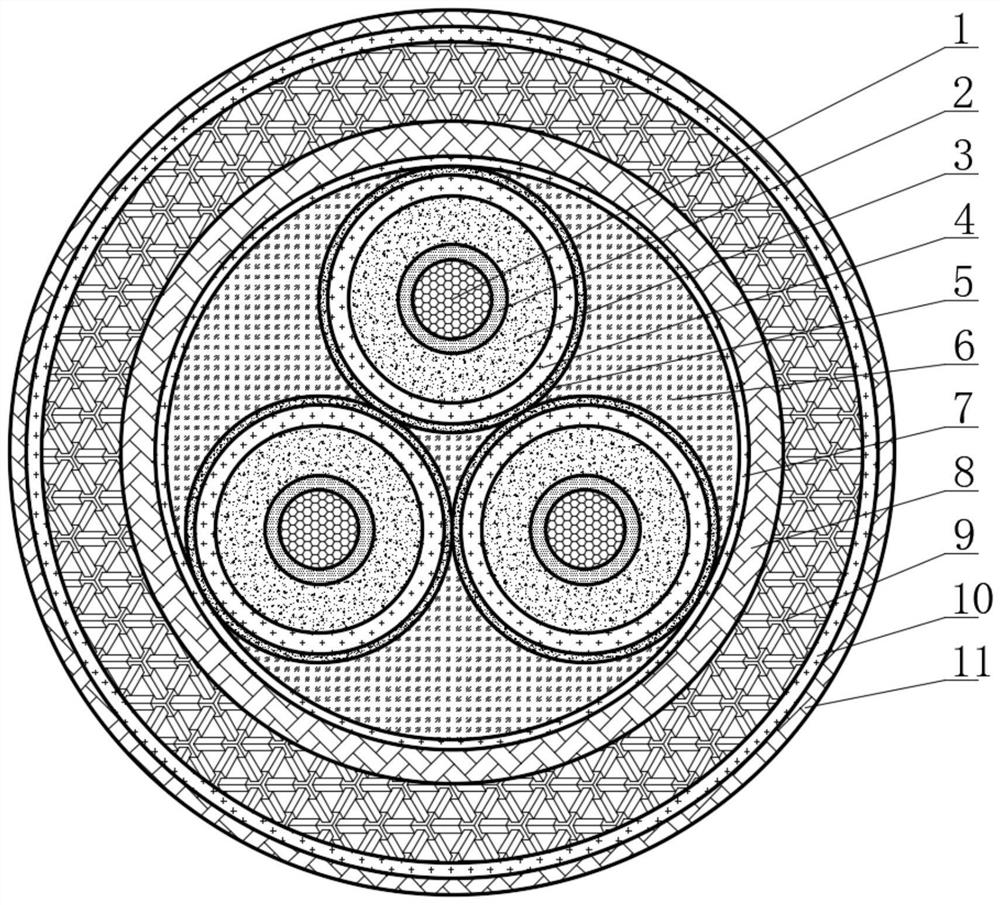

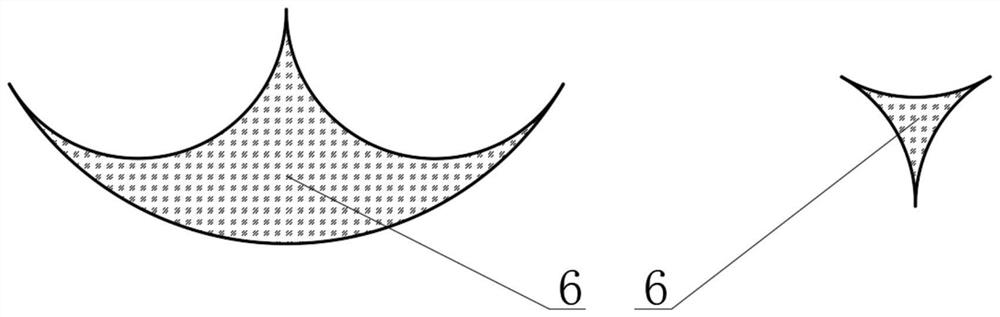

[0020] A long-lasting, solid, high-strength, self-reinforced submarine cable, which is a three-core cable structure as a whole, consisting of three individually wrapped core tubes and an outer protective sheath covering all the core tubes. The outer diameter of the submarine cable is 265mm, and its Each core 1 inside is made of 30 pure copper cores and compressed into a cylindrical core 1 with a diameter of φ38.2mm at a density of 91% using a polycrystalline mold, and the outer surface of each core 1 is covered with PVC Electrostatic coating film 2 made of material; each core tube is provided with a core body 1, an electrostatic coating film 2, an insulating layer 3, a single-core self-fixing water resistance belt 4 and a single-core coating layer 5 from the inside and the outside; the outer layer The protective cover is provided with an inner lining self-fixing water blocking tape 7, an inner lining layer 8, a steel wire armor layer 9, an outer lining self-fixing water blockin...

Embodiment 2

[0036] The whole is consistent with Example 1, the difference is:

[0037] The outer diameter of the submarine cable is 270mm, and each core 1 in it is made of 30 pure copper cores, which are compressed into a cylindrical core 1 with a diameter of φ38.8mm by a polycrystalline mold at a density of 89%. Self-fixing water blocking belt 4, inner lining self-fixing water blocking belt 7 and outer lining self-fixing water blocking belt 10 are all made of indium oxide: tin oxide: calcium oxide: magnesium oxide: iron oxide in a mass ratio of 27:3:1.8: The mixture mixed in the ratio of 1:0.6 is a semiconductor self-curing film that is first cured by NaOH aqueous solution with a mass concentration of 1.5% after being vapor-deposited on the surface of a flat pure copper plate, and then removed from the mold;

[0038] Wherein the manufacture method of semiconductor self-curing film comprises the following steps:

[0039] ① Raw material preparation: prepare indium oxide 270kg, tin oxide 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com