Preparation method of antibacterial silver-doped hydroxyapatite microspheres

A hydroxyapatite and silver doped technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low utilization rate, waste of empty shells, etc., and achieve added value and good crystallinity. , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

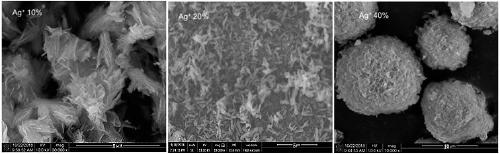

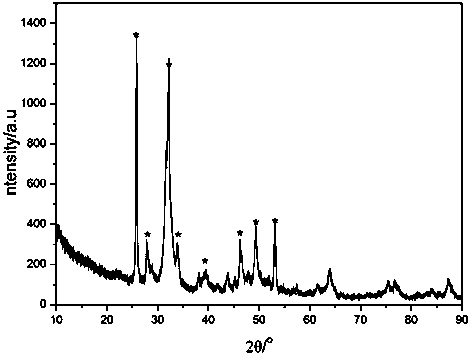

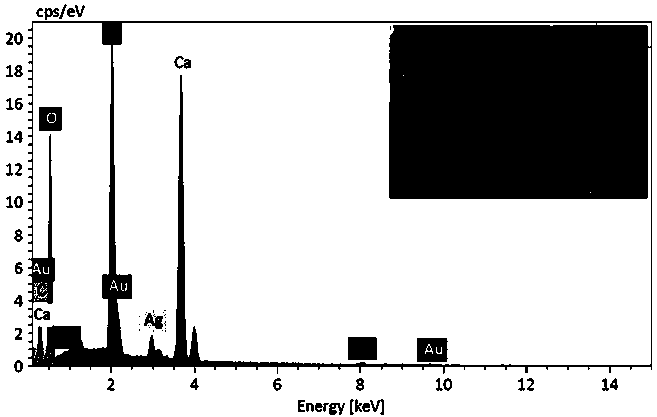

Embodiment 1

[0037] 1) The washed and dried oyster shells are crushed, ground, and screened with a 200-mesh filter to obtain oyster shell powder;

[0038] 2) Take 0.45g of oyster shell powder (Ca 2+ 0.0045mol), use 30ml of 10 vol.% acetic acid solution to dissolve, keep stirring until no bubbles are generated, then centrifuge at 4°C and 9000rpm for 5min, and take the supernatant;

[0039] 3) Dilute the supernatant to 50ml with deionized water, and add 50ml of phosphoric acid solution (0.06M) dropwise at a rate of 1ml / min under continuous stirring;

[0040] 4) After the phosphoric acid solution is added dropwise, add 0.2352g of sodium citrate and 0.085g of silver nitrate (Ag + 0.0005mol) and 6g of urea, and continued to stir for 0.5h to obtain a clear precursor reaction solution;

[0041] 5) Transfer the precursor reaction liquid obtained in step 4) to the reaction kettle, put it in an oven, and conduct a hydrothermal reaction at 90°C for 48 hours;

[0042] 6) After the reaction, take i...

Embodiment 2

[0044] 1) The washed and dried mussel shells are crushed, ground, and screened with a 200-mesh filter to obtain mussel shell powder;

[0045] 2) Take mussel shell powder 0.4g (Ca 2+ 0.004mol), use 20ml of 10 vol.% acetic acid solution to dissolve, keep stirring until no bubbles are generated, then centrifuge at 4°C and 9000rpm for 5min, and take the supernatant;

[0046] 3) Dilute the supernatant to 50ml with deionized water, and add 50ml of phosphoric acid solution (0.06M) dropwise at a rate of 1ml / min under continuous stirring;

[0047] 4) After the phosphoric acid solution is added dropwise, add 0.2352g of sodium citrate and 0.169g of silver nitrate (Ag + 0.001mol) and 6g of urea, and continued to stir for 0.5h to obtain a clear precursor reaction solution;

[0048] 5) Transfer the precursor reaction solution obtained in step 4) to the reaction kettle, put it in an oven, and conduct a hydrothermal reaction at 90°C for 36 hours;

[0049] 6) After the reaction, take it out ...

Embodiment 3

[0051] 1) Crush the washed and dried abalone shells, grind them, and screen them with a 200-mesh filter to obtain abalone shell powder;

[0052] 2) Take 0.3g of abalone shell powder (Ca 2+ 0.003mol), use 10ml of 10 vol.% acetic acid solution to dissolve, keep stirring until no bubbles are generated, then centrifuge at 4°C and 9000rpm for 5min, and take the supernatant;

[0053] 3) Dilute the supernatant to 50ml with deionized water, and add 50ml of phosphoric acid solution (0.06M) dropwise at a rate of 1ml / min under continuous stirring;

[0054] 4) After the phosphoric acid solution is added dropwise, add 0.2352g of sodium citrate and 0.338g of silver nitrate (Ag + 0.002mol) and 6g of urea, and continued to stir for 0.5h to obtain a clear precursor reaction solution;

[0055] 5) Transfer the precursor reaction liquid obtained in step 4) to the reaction kettle, put it in an oven, and conduct a hydrothermal reaction at 90°C for 48 hours;

[0056] 6) After the reaction, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com