Rare earth composite modified aluminum oxide and preparation method and application thereof

A technology of rare earth compounding and alumina, applied in the preparation of alkali metal aluminate/alumina/hydroxide, chemical instruments and methods, catalyst activation/preparation, etc., can solve specific surface area, pore volume, oxygen storage and release capacity To avoid problems such as decline, achieve excellent thermal stability, easy operation, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

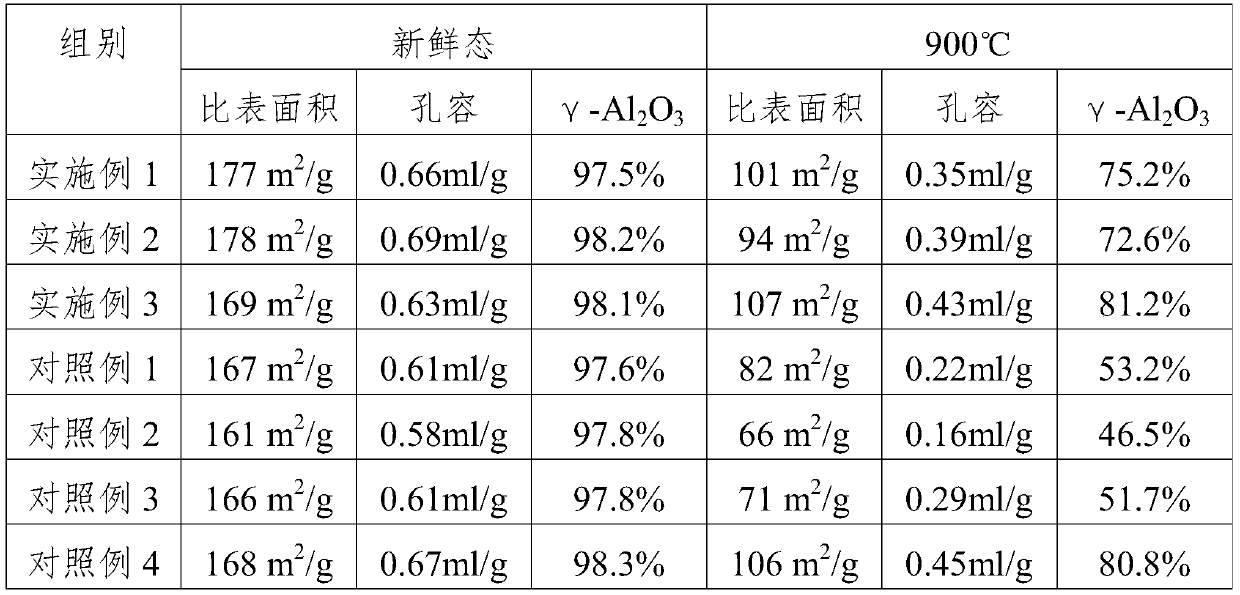

Examples

Embodiment 1

[0031] The embodiment of the present invention is a preparation method of rare earth composite modified alumina, the preparation method comprising the following steps:

[0032] (a) Add the sodium aluminate solution and the rare earth nitrate solution with a concentration of 150g / L into the dispersant solution to obtain a mixed solution, wherein the volume ratio of the sodium aluminate solution and the rare earth nitrate solution is 1:0.8, and the sodium aluminate The total volume of the solution and the rare earth nitrate solution to the volume ratio of the dispersant solution is 5:1, and the quality of the rare earth nitrate in the rare earth nitrate solution is 50% of the aluminum mass in the sodium aluminate solution, specifically 50% Including 8% lanthanum nitrate, 8% cerium nitrate, 8% zirconium nitrate, 6% thulium nitrate, 8% lutetium nitrate, 6% barium nitrate and 6% dysprosium nitrate, the solvent in the rare earth nitrate solution It is a nitric acid solution with a m...

Embodiment 2

[0036] The embodiment of the present invention is a preparation method of rare earth composite modified alumina, the preparation method comprising the following steps:

[0037] (a) Add the sodium aluminate solution and the rare earth nitrate solution with a concentration of 80g / L into the dispersant solution to obtain a mixed solution, wherein the volume ratio of the sodium aluminate solution and the rare earth nitrate solution is 1:1.2, and the sodium aluminate The total volume of the solution and the rare earth nitrate solution to the volume ratio of the dispersant solution is 7:1, and the quality of the rare earth nitrate in the rare earth nitrate solution is 10% of the aluminum mass in the sodium aluminate solution, specifically 10% Including 1.5% lanthanum nitrate and barium nitrate, 5% dysprosium nitrate, 3.5% thulium nitrate, the solvent in the rare earth nitrate solution is nitric acid solution with a mass fraction of 70%, and the dispersant in the dispersant solution i...

Embodiment 3

[0041] The embodiment of the present invention is a preparation method of rare earth composite modified alumina, the preparation method comprising the following steps:

[0042] (a) Add the sodium aluminate solution and the rare earth nitrate solution with a concentration of 100g / L into the dispersant solution to obtain a mixed solution, wherein the volume ratio of the sodium aluminate solution and the rare earth nitrate solution is 1:1, and the sodium aluminate The total volume of the solution and the rare earth nitrate solution and the volume ratio of the dispersant solution are 6:1, and the quality of the rare earth nitrate in the rare earth nitrate solution is 26% of the aluminum mass in the sodium aluminate solution, specifically 26%. Including 3% lanthanum nitrate and barium nitrate, 10% dysprosium nitrate, 8% zirconium nitrate and thulium nitrate and 5% lutetium nitrate, the solvent in the rare earth nitrate solution is nitric acid solution with a mass fraction of 65%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com