Preparation method of sea cucumber fucosan sulfate and chondroitin sulfate oligosaccharide

A technology of fucoidan sulfate and chondroitin sulfate, which is applied in the field of preparation of small molecular compounds, can solve the problems of cumbersome desalination steps and high cost of ion exchange chromatography columns, achieve simplified separation and degradation process, low cost and high absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Dried Apostichopus japonicus Dried sea cucumber is crushed into powder state. Weigh 10g powder, add 15mmol / L EDTA-Na2, 5mmol / L cysteine, 300mL 0.1mol / L pH 8.0 phosphate buffer solution, 500mg alkaline protease and 150mg trypsin, and stir in a water bath at 50°C for enzymolysis 24h. Afterwards, the reactant was boiled in a water bath for 5 min to inactivate the enzyme, and cooled to room temperature. Centrifuge at 5000×g for 10 min, and take the supernatant.

[0027] Add 16 mL of 10% cetylpyridinium chloride aqueous solution to the obtained supernatant (i.e. sea cucumber enzymatic hydrolysis solution), let stand at room temperature for 5 hours, centrifuge at 2000×g for 15 minutes at 20°C, discard the supernatant to obtain a precipitate .

[0028] The obtained precipitate was dissolved in 150 mL of NaCl ethanol solution (3 mol / L sodium chloride, 86% ethanol). Then add 300mL of 95% ethanol, place it at 4°C for 5h, centrifuge (4000×g, 15min, 20°C), and take the preci...

Embodiment 2

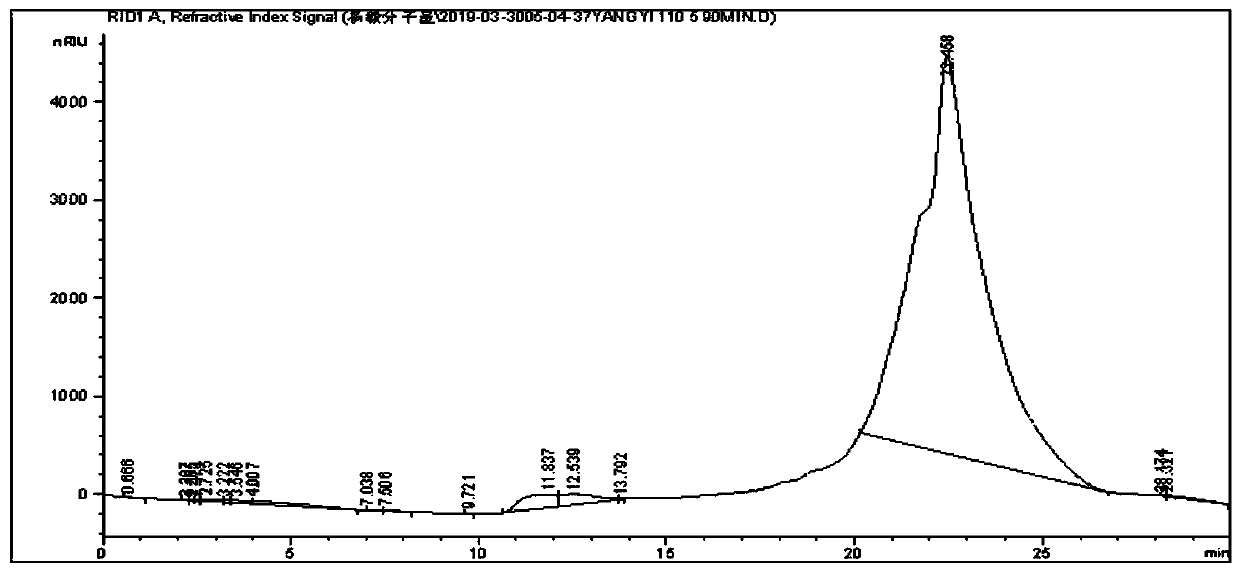

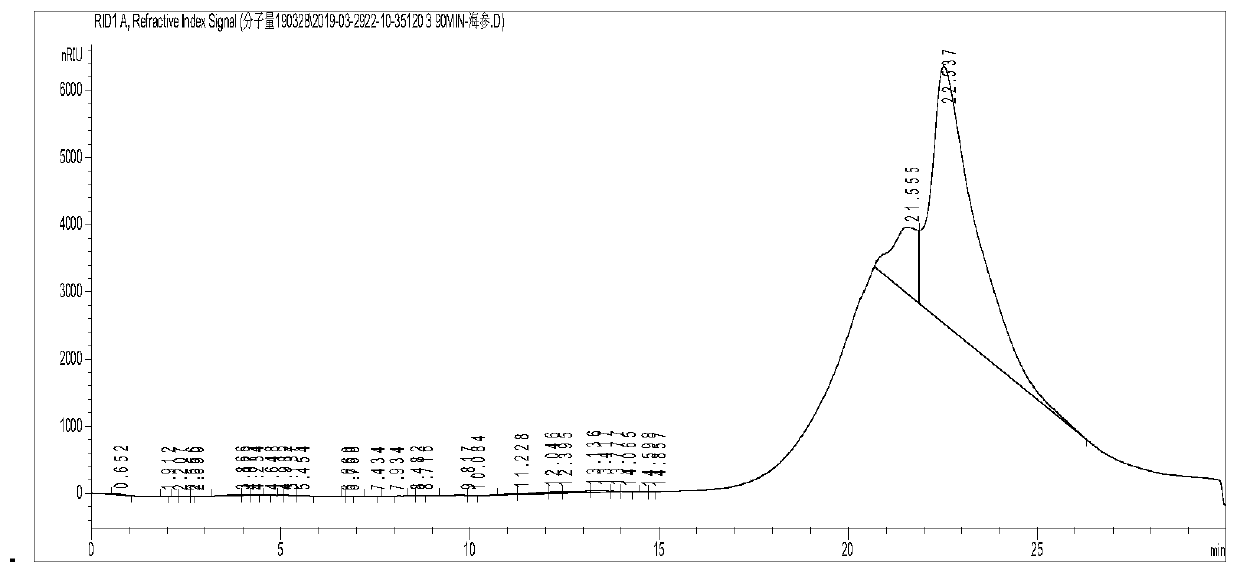

[0042] In order to specifically verify the influence of sample volume and degradation time on the prepared fucoidan sulfate and fucosyl sulfate chondroitin oligosaccharides in steps 3) and 5), change the sample volume and degradation time in steps 3) and 5). Time, all the other are with embodiment 1. The specific sample volume, degradation time and corresponding yield, molecular weight and sulfate content of fucoidan sulfate ester and fucosyl sulfate chondroitin oligosaccharide are shown in Table 2.

[0043] 2.1: The volume of the sea cucumber sulfated polysaccharide solution was increased to 100 mL for thermal degradation, and the yield of the obtained fucoidan sulfated oligosaccharides was 21.2%, and the yield of fucosyl chondroitin sulfated oligosaccharides was 43.2%. The weight average molecular weight of the fucoidan sulfate oligosaccharide is 4563.64Da, the number average molecular weight is 3213.83Da, and the dispersion coefficient is 1.42. The weight average of fucosy...

Embodiment 3

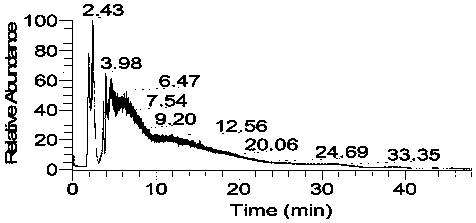

[0048] In order to verify the purity of the prepared fucoidan sulfate oligosaccharides and fucosyl chondroitin sulfate oligosaccharides, the liquid chromatography-mass spectrometry technique was used to analyze the fucoidan sulfate oligosaccharides and rock Composition of Cocosyl Chondroitin Sulfate Oligosaccharides.

[0049] 1) The method of liquid chromatography-mass spectrometry analysis is as follows: 10 mg / mL sulfated polysaccharide degradation products were mixed with acetonitrile in equal volumes, and then centrifuged at 10 000 r / min for 10 min. The supernatant was taken, and the composition and structure of oligosaccharides in the product were analyzed by high performance liquid chromatography-mass spectrometry. Chromatographic instrument: UltiMate 3000 high performance liquid chromatograph, liquid condition: chromatographic column is Luna 3μHILIC (2.0mm×150mm, ), mobile phase A is 5mmol / L ammonium acetate aqueous solution 10mL sea cucumber sulfate polysaccharide pH5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com