Self-healing microcapsule and preparation method thereof, self-healing basalt fiber and preparation method thereof

A technology of self-healing microcapsules and basalt fibers, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method for the self-healing microcapsules described in the above technical solution, comprising the following steps:

[0046] (1) urea, melamine and formaldehyde are mixed, carry out emulsification reaction, obtain prepolymer solution;

[0047] (2) Epoxy resin, diluent and emulsifier are mixed, carry out emulsification reaction and defoaming treatment successively, obtain core material emulsion;

[0048] (3) mixing the prepolymer solution with the core material emulsion, performing emulsification reaction and pH value adjustment treatment in turn to obtain liquid microcapsule particles; solidifying, filtering, washing and drying the liquid microcapsule particles in sequence Process to obtain monolayer microcapsules;

[0049] (4) providing a curing agent suspension containing a dispersant and a curing agent;

[0050] (5) mixing the curing agent suspension with the single-layer microcapsules, adjusting the pH value and h...

Embodiment 1

[0076] Put 5g of urea, 1g of melamine, and 13g of 37wt% formaldehyde aqueous solution into a 500mL three-neck flask with a condensing device in a mass ratio of 5:1:13, and stir for about 5min with a temperature-controlled magnetic stirrer at room temperature, and use a mass fraction of 10 % triethanolamine to adjust the pH of the solution to 8.5, use 1.5mL of triethanolamine, heat up at 70°C and react for 1h to obtain a transparent and viscous prepolymer solution, quickly add 40mL deionized water to dilute the prepolymer solution (follow-up involves prepolymerization The amount of polymer used is calculated based on the amount of prepolymer before dilution), cooled to room temperature for later use.

[0077] Add a mixture of 10g of epoxy resin E-51 and 2.5g of diluent ethyl phenylacetate (mass ratio 5:1) into a 500mL three-neck flask, stir for 10min, then weigh 0.5g of emulsifier dodecylbenzenesulfonic acid Dissolve sodium in 40mL deionized water, add it to the flask, stir and...

Embodiment 2

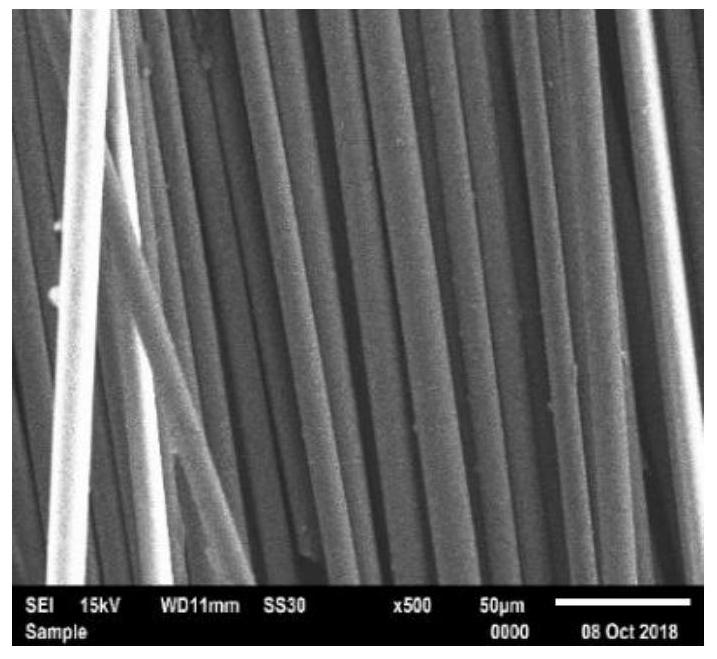

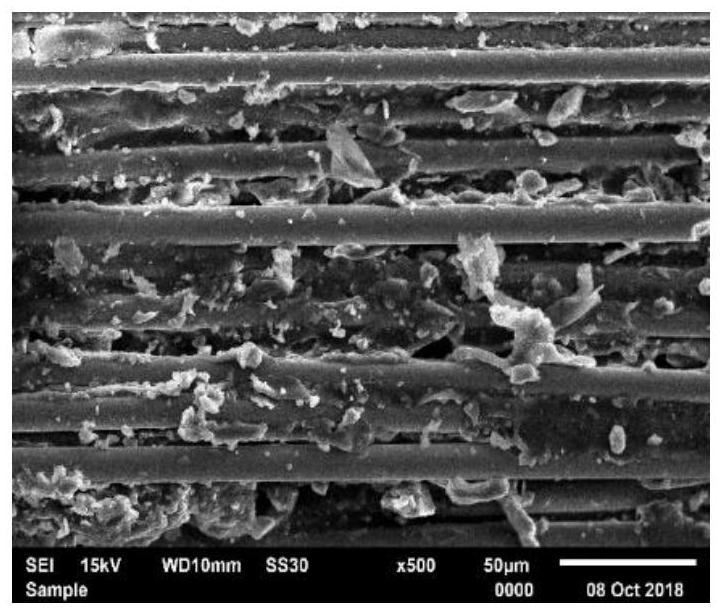

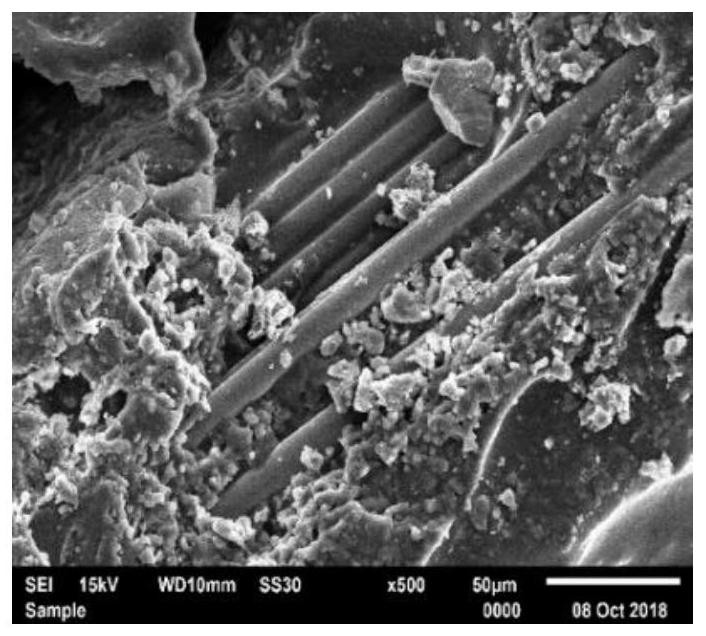

[0083] Take a certain length of basalt fiber fabric and dry it in an oven at 250°C for 2 hours to remove the sizing agent on the surface. Subsequently, 5 g of self-healing microcapsules (double-layer microcapsules) prepared in Example 1 were added to 2.5 g of water-based polyurethane, fully stirred for 1 h at a speed of 1000 r / min, and prepared into a finishing solution for subsequent use. Pour the prepared finishing solution containing self-healing microcapsules into the dipping tank, and coat the basalt yarn by padding process at a coating speed of about 40m / min, then place the finished basalt yarn in a vacuum oven Dry at 45°C for 2 hours to prepare self-healing basalt fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com