Preparation method of flexible packaging film

A technology of flexible packaging film and resin film, which is applied in the field of preparation of flexible packaging film, can solve the problems of biological and environmental hazards, limited improvement effect, and affect the performance of resin film, achieve excellent compactness, improve interlayer stability, and good physical properties Barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for a flexible packaging film, comprising the steps of:

[0031] (1) Surface treatment of aluminum alloy foil

[0032] Select soft-end aluminum-magnesium alloy foil for flexible packaging batteries, grade 8011, bright on one side, thickness 40 μm, elongation at break 22%; use German Henkel aluminum alloy acid degreasing agent Ridoline 560, formulated with a mass solubility of 5 % aqueous solution; the specific technological process of the surface treatment of aluminum alloy foil is as follows: soak the aluminum alloy foil in the degreasing agent solution at a temperature of 40°C for 30s, take out the cold water to spray and clean it, and dry it under hot air at a temperature of 100°C. Then after natural cooling, stand-by;

[0033] (2) Preparation of silane solution

[0034] Select gamma-aminopropyltriethoxysilane coupling agent (KH-550), and mix it with ethanol and deionized water in a mass ratio of 1:12:1 to prepare a mixed solution; select glaci...

Embodiment 2

[0047] The specific steps are as in Example 1, the difference is that glycidyl etheroxypropyltrimethoxysilane (KH-560), bis(3-triethoxysilylpropyl)amine (KH270 ) Two silane coupling agents, the ratio is 1:0.2. Methanol and ethanol are mixed in any proportion to obtain an alcohol mixture, and then silane, alcohol mixture, and deionized water are mixed in a mass ratio of 1:10:1. Then dilute it with deionized water to form a silane solution with a mass solubility of 5%. Graphene oxide powder LGO1111 from Changzhou Angxing Company was selected, with a single-layer sheet diameter of 5-40nm, an average thickness of 1nm, and an exfoliation rate of >95%.

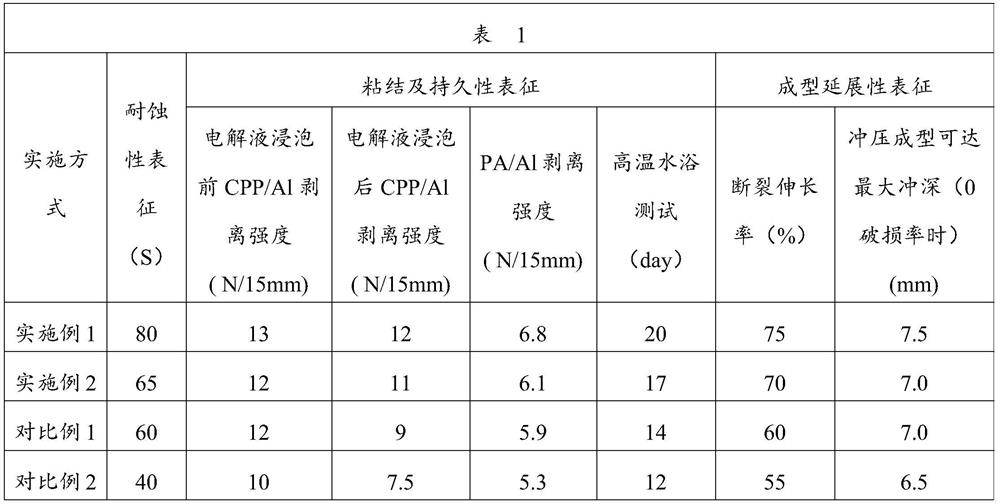

[0048] The same performance characterization test was carried out as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com