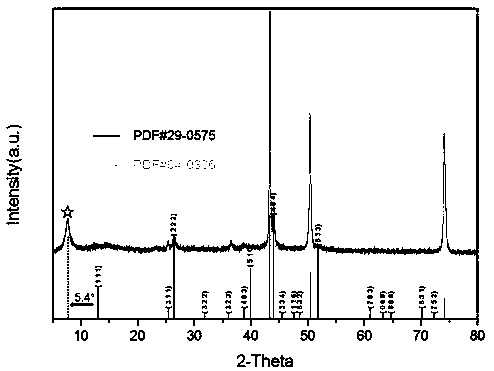

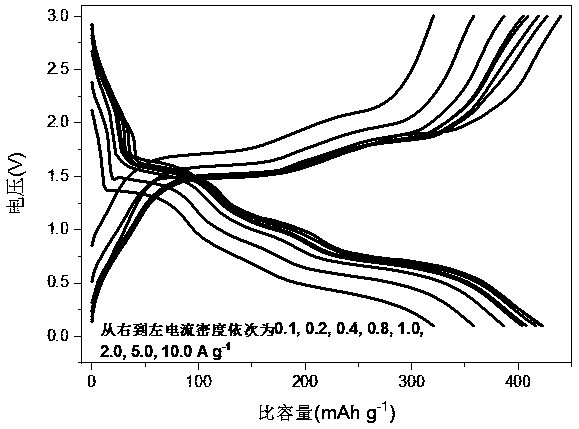

Preparation method and application of copper selenide nanosheet array for sodium ion battery with adjustable interlayer spacing

A sodium-ion battery and nanosheet array technology, which is applied in the field of preparation of copper selenide nanosheet arrays for sodium-ion batteries, can solve the problems of unsuitability for large-scale production, high energy-consuming equipment, and high production costs, and achieve easy industrialization. The effect of large-scale production, low cost and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

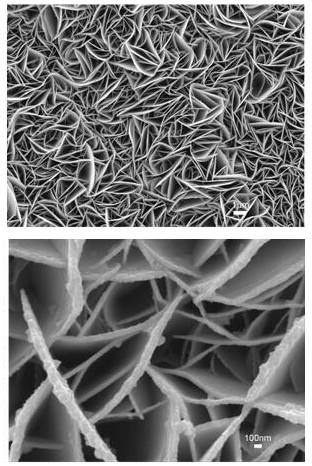

[0034] The preparation method of a copper selenide nanosheet array for a sodium ion battery with adjustable layer spacing in this embodiment is as follows:

[0035] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0036] (2) Dissolve 4 g sodium hydroxide in 100 ml, 0.001 mol L -1 0.110 g (0.001 mol) of selenium dioxide and 0.189 g (0.005 mol) of sodium borohydride were added in sequence, and stirred rapidly at 20°C for 10 min to completely dissolve the raw materials to obtain solution A.

[0037] (3) Put the copper foil treated in step (1) in solution A, react at 20 °C for 4 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array fo...

Embodiment 2

[0045] The preparation method of a copper selenide nano-array for a sodium-ion battery with adjustable layer spacing in this embodiment is as follows:

[0046] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0047] (2) Dissolve 8 g sodium hydroxide in 100 ml, 0.005 mol L -1 0.346 g (0.002 mol) of sodium selenite and 0.378 g (0.01 mol) of sodium borohydride were added in sequence, and stirred rapidly at 30°C for 30 minutes to completely dissolve the raw materials to obtain solution A.

[0048] (3) Put the copper foil treated in step (1) in solution A, react at 30 °C for 4 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array for s...

Embodiment 3

[0051] The preparation method of a copper selenide nano-array for a sodium-ion battery with adjustable layer spacing in this embodiment is as follows:

[0052] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0053] (2) Dissolve 10 g sodium hydroxide in 100 ml, 0.01 mol L -1 0.237 g (0.003 mol) of selenium powder and 0.81 g (0.015 mol) of potassium borohydride were added in sequence, and stirred rapidly at 40 °C for 60 min to completely dissolve the raw materials to obtain solution A.

[0054] (3) Put the copper foil treated in step (1) in solution A, react at 40 °C for 3 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com