Preparation method and applications of additional carbon resource used for denitrification

A carbon source, denitrification technology, applied in chemical instruments and methods, anaerobic digestion treatment, water treatment parameter control, etc., can solve the problems of increasing the operating cost of urban sewage treatment plants, poor denitrification effect, and complicated operation process. , to achieve the effect of resource utilization, rapid response and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

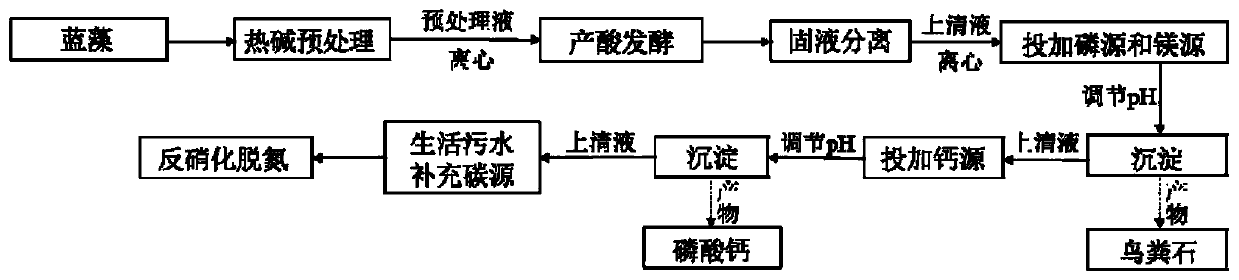

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Cyanobacteria anaerobic fermentation produces acid

[0038] In this embodiment, the specific implementation steps of mixing the cyanobacteria pretreated with hot alkali and anaerobic granular sludge for anaerobic fermentation to produce acid are as follows:

[0039] The cyanobacteria are pretreated with hot alkali (pH 12, temperature 105°C, time 2h) to obtain a cyanobacteria pretreatment liquid. Take a 500mL reaction bottle, add 300mL cyanobacteria pretreatment solution, add seed sludge at a mass ratio of 1:5 to the substrate, and purge the headspace of the reaction bottle with high-purity nitrogen for 5 minutes to maintain an anaerobic environment. Reaction, fermentation time is 10d. After the fermentation mixture was centrifuged (8000rpm, 10min), the supernatant was taken and placed in a 4°C refrigerator for later use. The properties of the cyanobacteria anaerobic acid production fermentation broth are shown in Table 1.

[0040] In the cyanobacteria a...

Embodiment 2

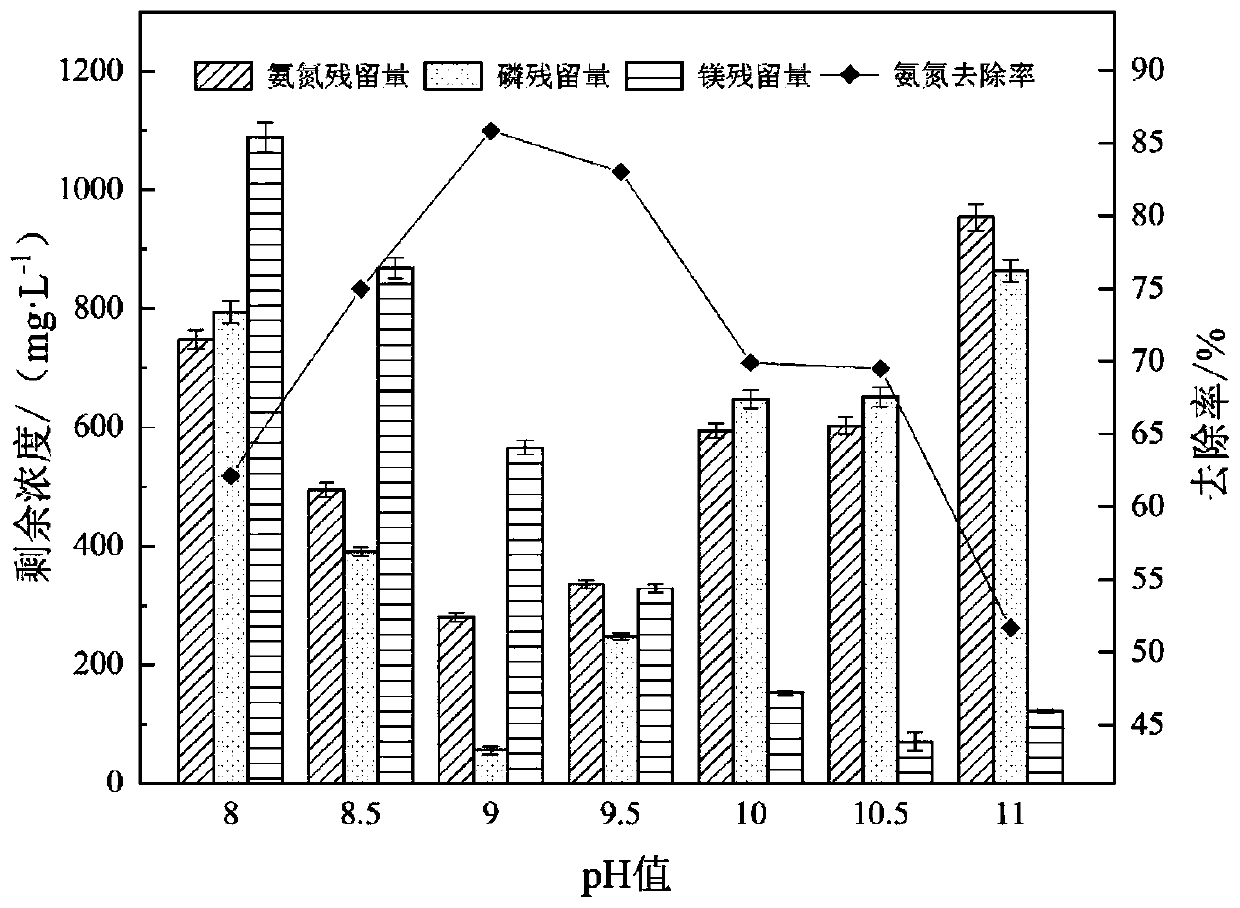

[0043] Example 2: Effects of different pH values on recovery of ammonia nitrogen in cyanobacteria anaerobic acid production fermentation broth by struvite precipitation method

[0044]Take 200mL of cyanobacteria anaerobic acid production fermentation liquid in a 500mL beaker, add potassium dihydrogen phosphate and magnesium chloride hexahydrate to make the molar ratio of Mg / P / N 1 / 1 / 1, adjust the pH of the solution with 6M sodium hydroxide solution , adjust the pH value to 8, 8.5, 9, 9.5, 10, 10.5, 11 respectively, stir with a magnetic stirrer at 300rpm, react for 30min, let stand for 30min, take the supernatant to measure various indicators.

[0045] figure 2 The effect of struvite precipitation method on recovery of ammonia nitrogen in cyanobacteria fermentation broth under different pH conditions. It can be seen that with the increase of pH, the removal of ammonia nitrogen first increases and then decreases. When the pH increased from 8 to 9, the removal rate of ammonia...

Embodiment 3

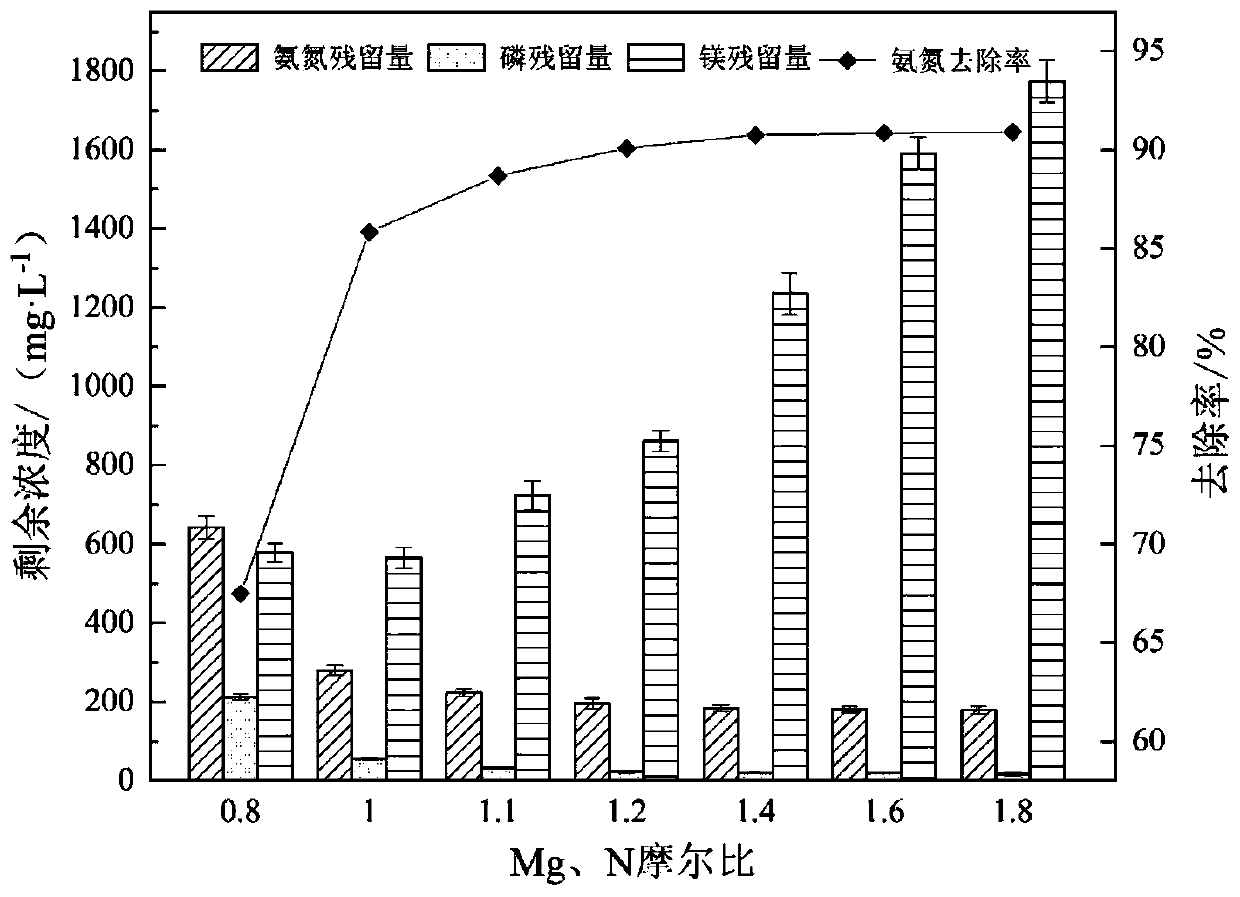

[0046] Example 3: Effects of different Mg and N molar ratios on struvite recovery from cyanobacteria anaerobic acid production fermentation liquid ammonia nitrogen

[0047] With reference to the operating steps of Example 2, the pH of the solution is adjusted to 9 with 6M sodium hydroxide solution, and the dosage of potassium dihydrogen phosphate is fixed, wherein the mol ratio of P / N is 1 / 1, and the consumption of magnesium chloride hexahydrate is changed Dosing amount, react under the condition that the molar ratio of Mg / N is 0.8 / 1, 1 / 1, 1.1 / 1, 1.2 / 1, 1.4 / 1, 1.6 / 1, 1.8 / 1, and use a magnetic stirrer at 300rpm Stir, react for 30 minutes, let stand for 30 minutes, take the supernatant to measure various indicators.

[0048] image 3 The effect of struvite precipitation to recover ammonia nitrogen in cyanobacteria anaerobic acidogenic fermentation broth under different Mg and N molar ratio conditions. It can be seen that the removal rate of ammonia nitrogen increases significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com