A method for surface photoinitiated preparation of porous adsorbent with high density crown ether sites

A porous adsorbent, high-density technology, applied in chemical instruments and methods, process efficiency improvement, other chemical processes, etc., can solve problems such as selectivity to be improved, low site density, poor adsorption performance, etc., to avoid binding The effect of instability, improved kinetics, simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

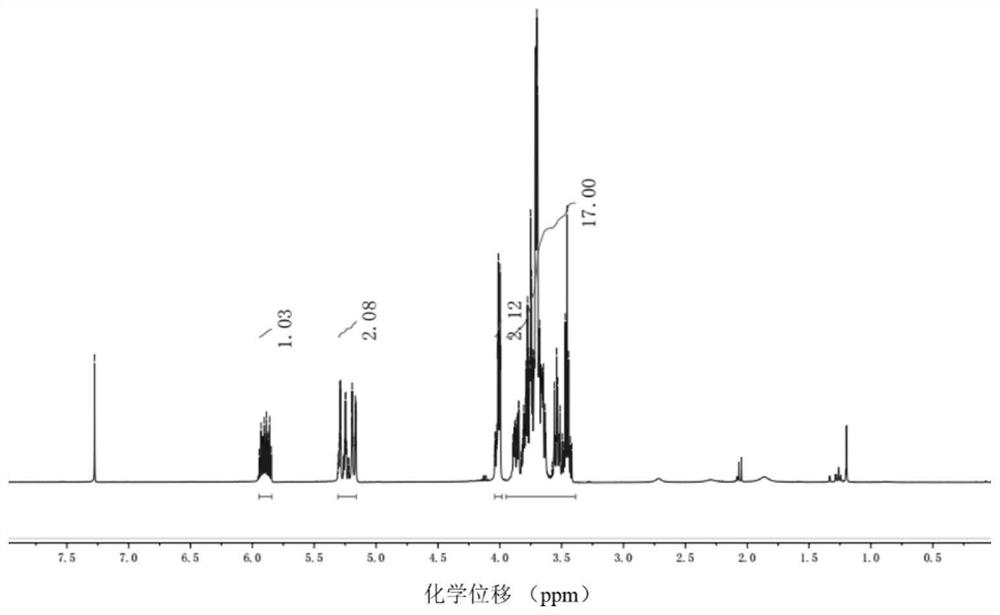

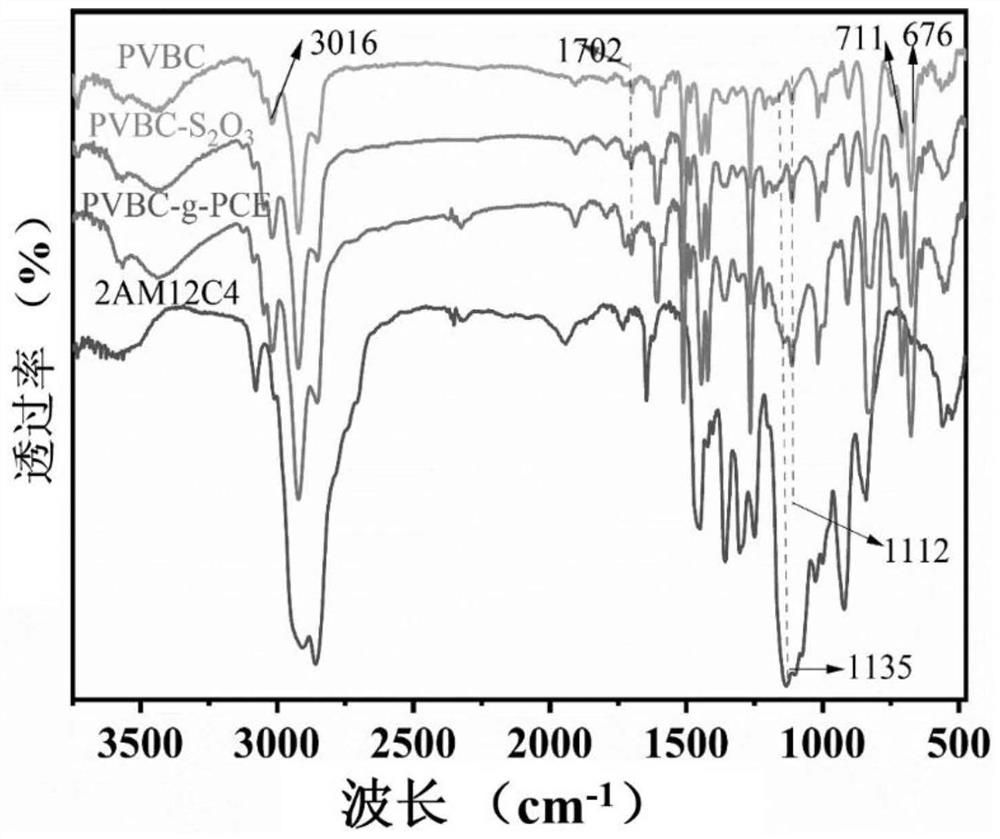

[0041] (1) Preparation of 2AM12C4;

[0042] Mix 9 mmol of 30% potassium hydride dispersion in mineral oil with 1.9 mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 30 mL of DMF for 30 min at room temperature, then add 10 mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane with a volume ratio of 1:2: EtOAc to obtain 2AM12C4;

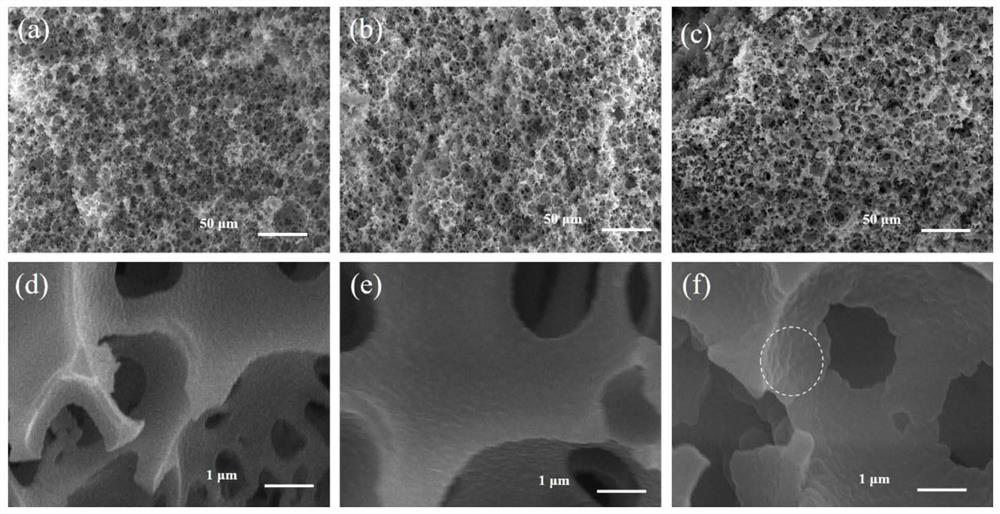

[0043] (2) Preparation of porous polymer (PVBC) with chloromethyl groups on the surface;

[0044] Add 3.0mL of 4-VBC, 0.5mL of EGDMA, and 30mg of AIBN into a 100mL three-neck flask, and sonicate for 5.0min to completely dissolve AIBN. Under mechanical stirring at 500rpm, slowly add 1.0mL Hy...

Embodiment 2

[0055] (1) Preparation of 2AM12C4;

[0056] Mix 12 mmol of 30% potassium hydride dispersion in mineral oil with 2.2 mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 40 mL of DMF for 30 min at room temperature, then add 12 mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane:EtOAc with a volume ratio of 1:2 to obtain 2AM12C4;

[0057] (2) preparation of porous polymer (PVBC);

[0058] Add 4.0mL of 4-VBC, 0.67mL of EGDMA, and 40mg of AIBN into a 100mL three-necked flask, and sonicate for 8.0min to completely dissolve AIBN. Under mechanical stirring at 700rpm, slowly add 1.34mL Hypermer 2296 dropwise to the flask, a...

Embodiment 3

[0064] (1) Preparation of 2AM12C4;

[0065] Mix 15 mmol of 30% potassium hydride dispersion in mineral oil with 2.5 mmol of 2-hydroxymethyl-12-crown-4 (2M12C4) in 50 mL of DMF for 30 min at room temperature, then add 15 mmol of allyl bromide , the reaction was quenched with methanol after stirring overnight, methanol was then evaporated under reduced pressure, the product was washed three times with water, and then washed with CH 2 Cl 2 Extraction with MgSO 4 Dry and filter. The solvent was removed by rotary evaporation and the residue was purified by column chromatography with SiO as stationary phase 2 , the mobile phase is hexane:EtOAc with a volume ratio of 1:2 to obtain 2AM12C4;

[0066] (2) preparation of porous polymer (PVBC);

[0067] Add 5.0mL of 4-VBC, 0.83mL of EGDMA, and 50mg of AIBN into a 100mL three-necked flask, and sonicate for 10.0min to completely dissolve AIBN. Slowly add 1.67mL Hypermer 2296 dropwise to the flask under mechanical stirring at 1000rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com