Preparing method of water-soluble ocean oligo-polysaccharides

A technology of oligomeric polysaccharides and marine polysaccharides, applied in the marine field, can solve the problems of easily destructive polysaccharides, active groups, poor applicability of enzymatic hydrolysis, energy consumption and high noise, etc., and achieve product uniformity and solubility improvement, crystallinity The effect of reducing and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing water-soluble marine oligopolysaccharides, comprising: providing high-molecular-weight marine polysaccharides; providing electron flow, and the above-mentioned electron flow degrades the above-mentioned polysaccharides by ionizing radiation; providing a separation and purification process to obtain oligopolysaccharides with excellent water solubility; The molecular weight of the above-mentioned oligopolysaccharide is 1×10 3 -5×10 4 Da. This method uses electron current irradiation to degrade high-molecular-weight polysaccharides, and free radicals are generated in the system to attack glycosidic bonds to break them, so as to realize the fragmentation of high-molecular polysaccharides, achieve the purpose of reducing molecular weight, and obtain low-molecular-weight polysaccharides with excellent biological activity. The method has high reproducibility and controllability, no environmental pollution, no significant change in the main chain structu...

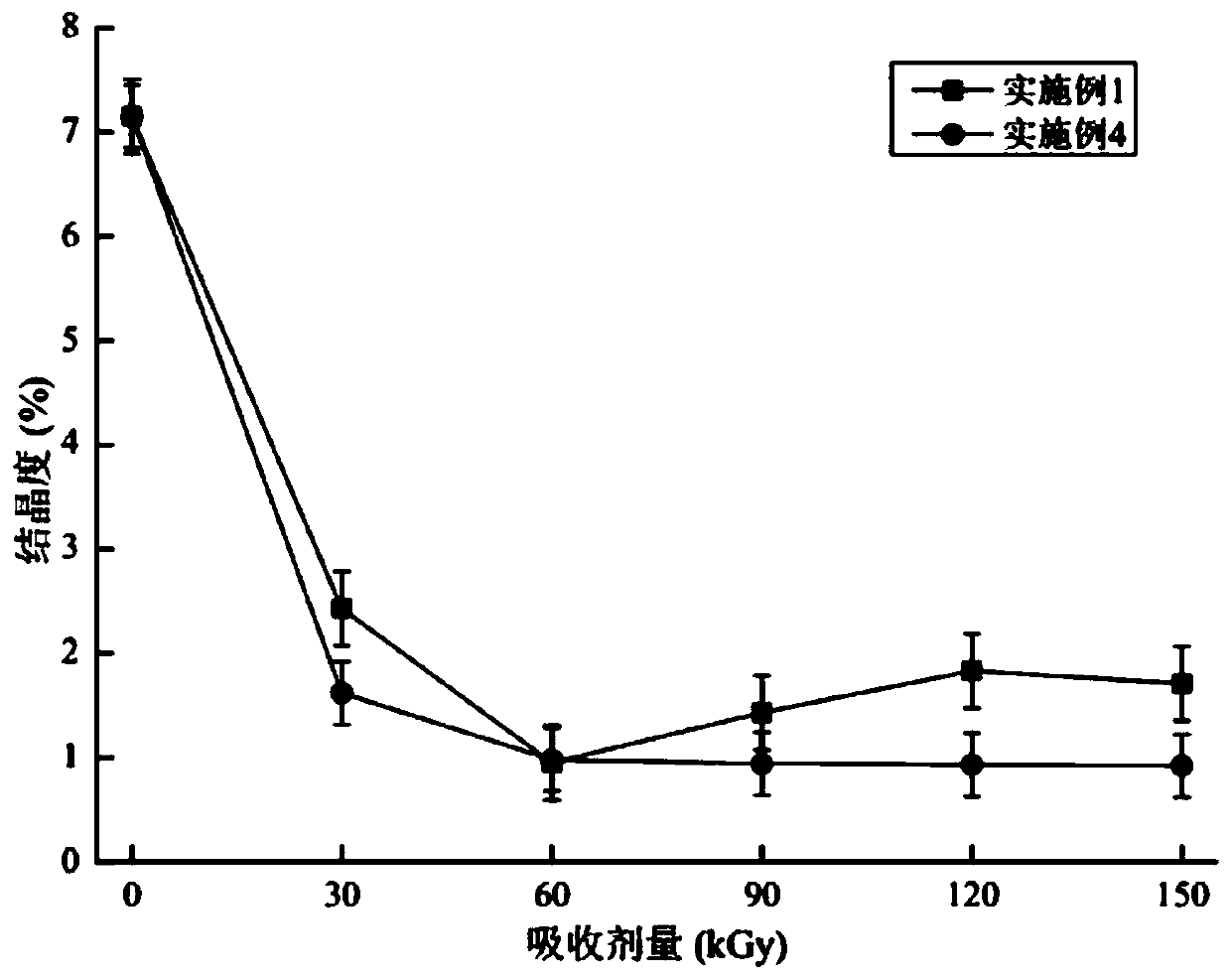

Embodiment 1

[0033] A kind of preparation method of water-soluble marine oligopolysaccharide, its concrete steps are as follows:

[0034] (1) high molecular weight chitosan (weight average molecular weight M W 500,000) dispersed in water to form a water dispersion system with a mass concentration of 15%, then the system was left to stand for 12 hours, and then the container was sealed and placed at a temperature of 30°C, an absorbed dose of 200kGy, and a radiation dose rate of 10kGy / Beta ray irradiation under the condition of min;

[0035] (2) After irradiation, the water dispersion system was left to stand for 2h, centrifuged, and the supernatant was dried in a 60°C oven to obtain powdered low molecular weight chitosan, and the product was prepared into a solution with a concentration of 1%. The molecular weight of chitosan was determined by gel permeation chromatography: the mobile phase used was: 0.12mol CH3COOH / 0.06mol CH3COONa aqueous solution, the column temperature was 35°C, and t...

Embodiment 2

[0037] A kind of preparation method of water-soluble marine oligopolysaccharide, its concrete steps are as follows:

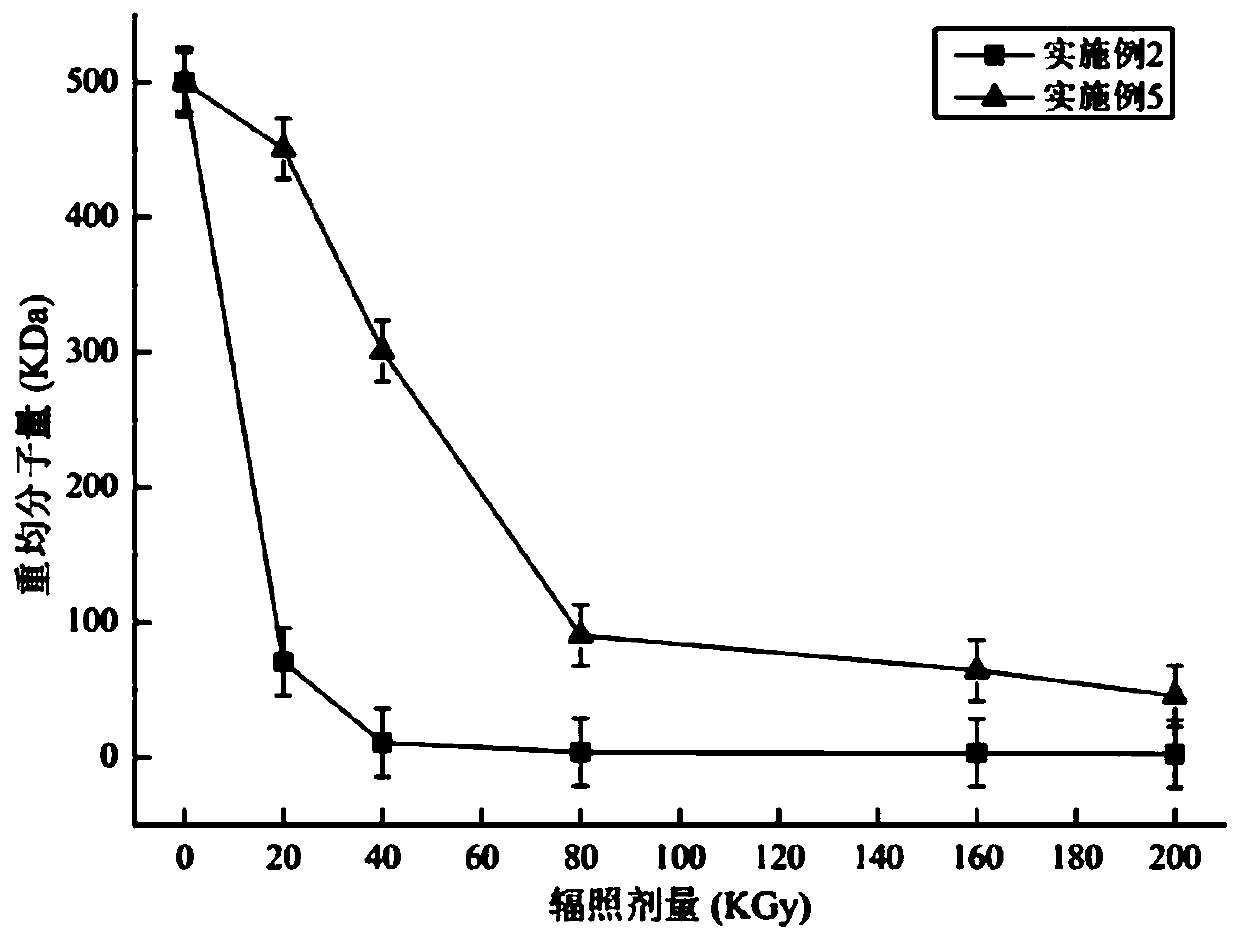

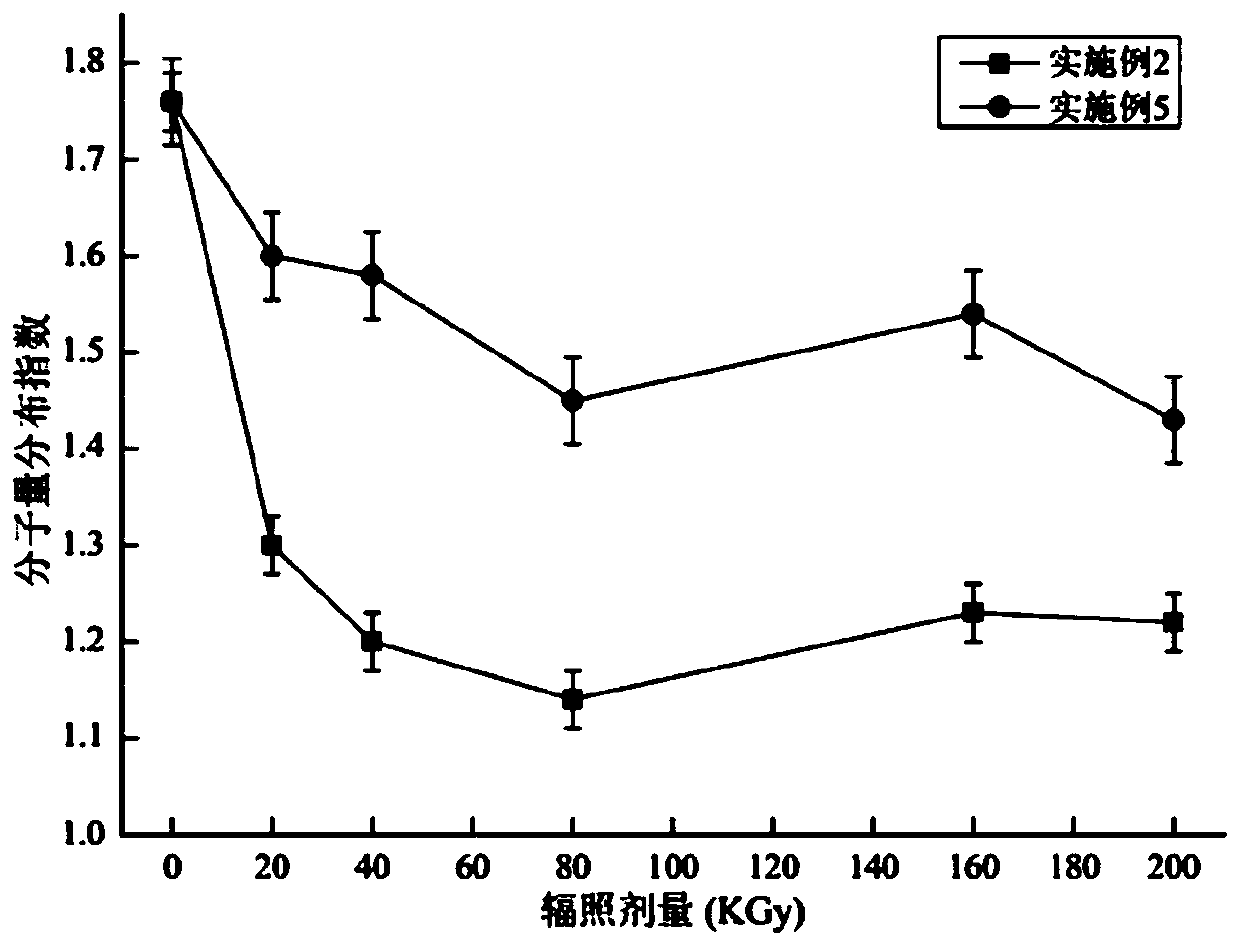

[0038] (1) get 5 parts of high molecular weight chitosan (weight average molecular weight M) of 1g respectively W 500,000) dispersed in water to form a water dispersion system with a mass concentration of 25%, then the system was left to stand for 12 hours, and then the container was sealed and sealed, and placed under the conditions of a temperature of 30°C and a radiation dose rate of 10kGy / min. Beta ray irradiation, and set the absorbed dose of each group to be 20, 40, 80, 160, 200kGy respectively;

[0039] (2) After irradiation, the water dispersion system was left to stand for 2 hours, centrifuged, and the supernatant was dried in an oven at 60°C to obtain powdery low molecular weight chitosan with different molecular weights, which were obtained by multi-angle laser scattering (SEC-MALLS ) to determine the relative molecular weight of the same concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com