Preparation technology of polyunsaturated fatty acid microcapsule powder

A technology of unsaturated fatty acid and microcapsule powder, applied in the field of food processing, can solve the problems of oil leakage, oxidation, heavy fishy smell, etc., and achieve the effects of reducing addition, improving emulsifying activity and preventing fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

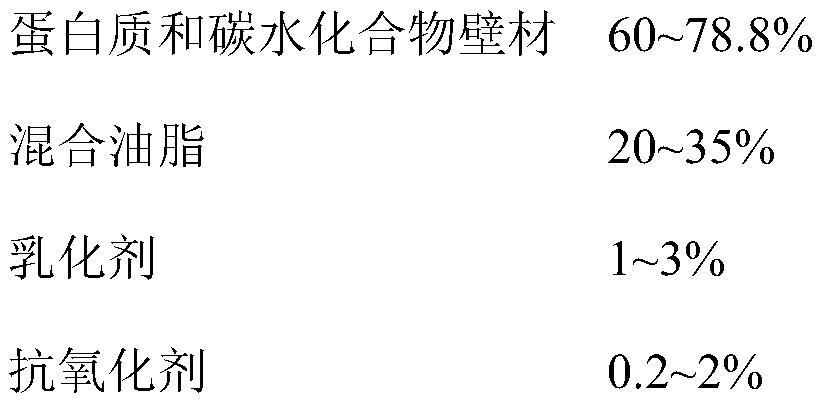

Method used

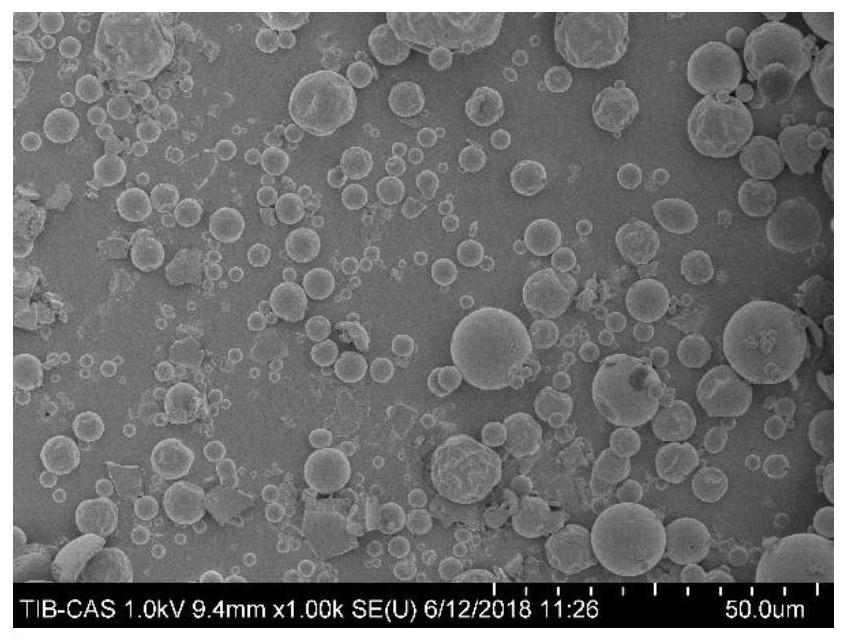

Image

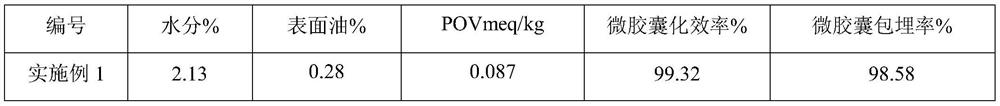

Examples

Embodiment 1

[0029] Step 1. After mixing 1 weight part of water and 2 weight parts of DHA (docosahexaenoic acid) algal oil, adjust the pH value to 5, add lipase to it and stir at a temperature of 35 ° C, while stirring Filling with nitrogen, reacting for 3h to obtain a first mixed solution, and mixing the first mixed solution with KOH-ethanol solution to obtain a second mixed solution;

[0030] Step 2, after adding n-hexane to the second mixed solution and shaking, to obtain the upper layer solution and lower layer solution containing glycerol DHA ester, get the upper layer solution and carry out vacuum distillation for 20min to obtain glycerol DHA ester;

[0031] Step 3: After adjusting the pH value of the lower layer solution to 1, add n-hexane to obtain an extract phase, dehydrate the extract phase and dry it with nitrogen to obtain free fatty acid, mix 3.5-10 parts by weight of free fatty acid and maltodextrin and add it to water And adjust the pH value to 7, then add lipase and stir f...

Embodiment 2

[0036] Step 1. After mixing 1 weight part of water and 7 weight parts of DHA algae oil, adjust the pH value to 8, add lipase to it and stir at a temperature of 55 ° C, fill with nitrogen while stirring, and the reaction obtains the first. Mixed solution, the first mixed solution is mixed with KOH-ethanol solution to obtain the second mixed solution;

[0037] Step 2, after adding n-hexane to the second mixed solution and shaking, the upper layer solution and the lower layer solution of glycerol DHA ester are obtained, and the upper layer solution is taken and subjected to vacuum distillation for 20min to obtain glycerol DHA ester;

[0038] Step 3. After adjusting the pH value of the lower layer solution to 3, add n-hexane to obtain an extraction phase, dehydrate the extraction phase and dry it with nitrogen to obtain free fatty acid, mix 10 parts by weight of free fatty acid and maltodextrin, add water and adjust The pH value reached 9.5, then lipase was added and stirred for 1...

Embodiment 3

[0043] Step 1. After mixing 1 weight part of water and 5 weight parts of DHA algae oil, adjust the pH value to 7, add lipase to it and stir at a temperature of 45 ° C, fill with nitrogen while stirring, and the reaction obtains the first. Mixed solution, the first mixed solution is mixed with KOH-ethanol solution to obtain the second mixed solution;

[0044] Step 2, after adding n-hexane to the second mixed solution and shaking, to obtain the upper layer solution and lower layer solution containing glycerol DHA ester, get the upper layer solution and carry out vacuum distillation for 20min to obtain glycerol DHA ester;

[0045] Step 3. After adjusting the pH value of the lower layer solution to 2, add n-hexane to obtain an extraction phase, dehydrate the extraction phase and dry it with nitrogen to obtain free fatty acid, mix 8 parts by weight of free fatty acid and maltodextrin, add water and adjust The pH value reached 8, then lipase was added and stirred for 10 hours at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com