Plant composition for treating hyperuricemia and gout and plant composition solid granules

A technology of hyperuricemia and composition, which is applied in the fields of food and medicine, can solve problems such as injury, increased risk of stroke, hypersensitivity allergic syndrome, etc., achieves reduction of serum uric acid and urinary uric acid levels, prolonged action time, Immunity-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

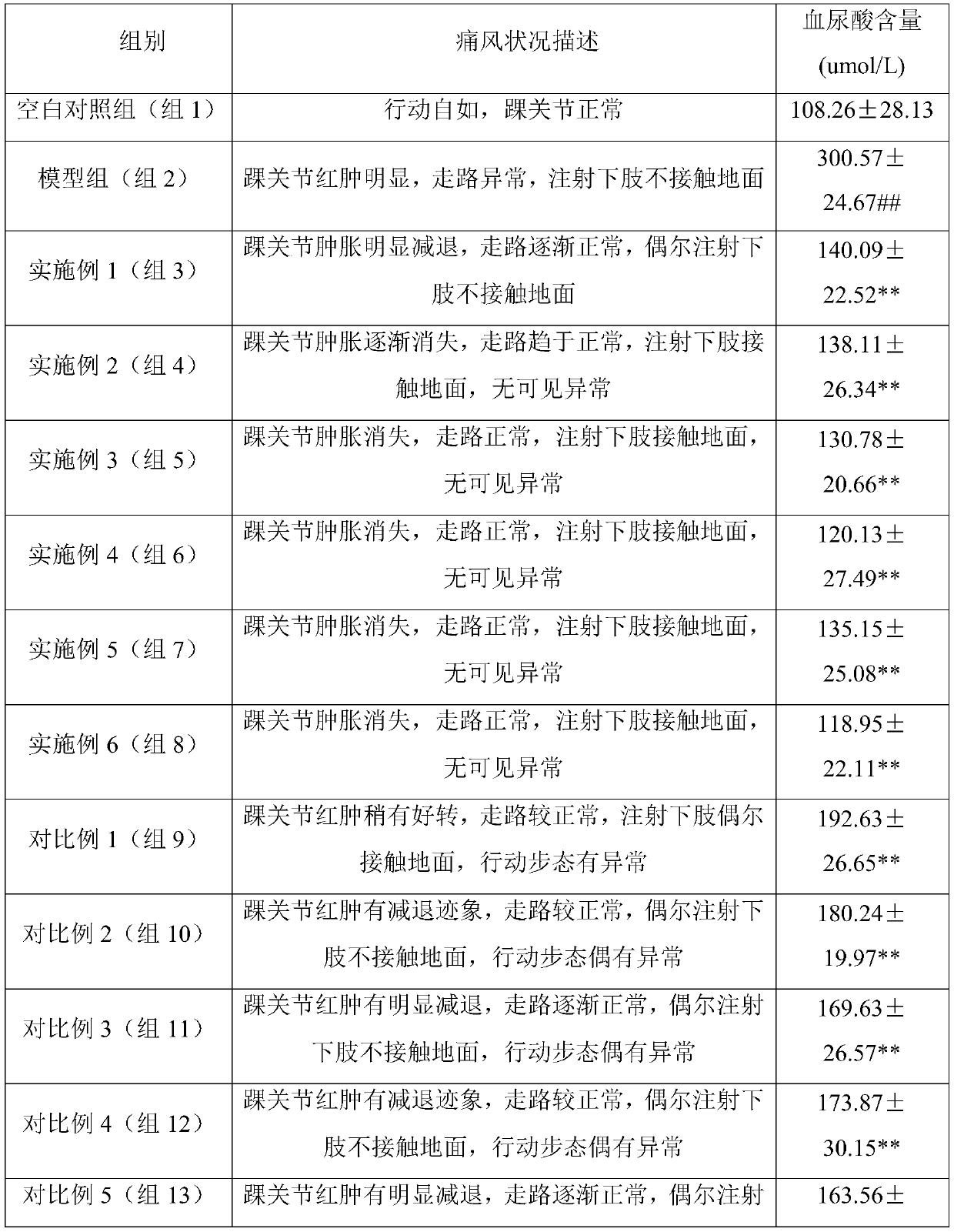

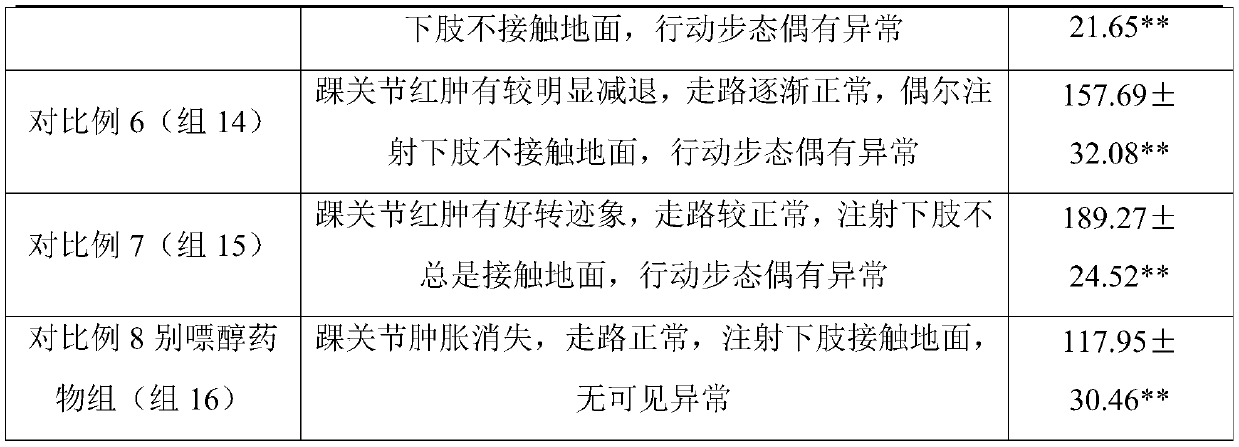

Examples

Embodiment 1

[0045] A method for preparing solid particles of a plant composition, by mass percentage, the plant composition, auxiliary materials, isomalt, flavoring agent and essence are mixed uniformly, a 50wt% ethanol aqueous solution is used to prepare a soft material, and an 18-mesh sieve is used to prepare a soft material. Net granulation, drying at 50°C for 4.5 hours to obtain solid particles of plant composition, wherein, in parts by mass, the ratio of plant composition, auxiliary material, isomalt, flavoring agent and essence is 45:35:20: 0.3:0.1, the auxiliary materials are pregelatinized starch and resistant dextrin, and the ratio of pregelatinized starch and resistant dextrin is 15:20 in parts by mass. In parts by mass, the plant composition consists of 1 part of celery seed extract, 1 part of corn silk powder, 1 part of pumpkin powder, 1 part of lotus leaf powder, 1 part of mulberry powder, and 1 part of ginseng powder Mixed with 1 part of grape powder.

Embodiment 2

[0047]A method for preparing solid particles of a plant composition, by mass percentage, the plant composition, auxiliary materials, isomalt, flavoring agent and essence are mixed uniformly, a 60wt% ethanol aqueous solution is used to prepare a soft material, and an 18-mesh sieve is used to prepare a soft material. Net granulation, drying at 50°C for 4 hours to obtain solid particles of plant composition, wherein, in parts by mass, the ratio of plant composition, auxiliary material, isomalt, flavoring agent and essence is 50:40:10: 0.3:0.1, the excipients are sorbitol and resistant dextrin, and the ratio of sorbitol and resistant dextrin is 25:15 in parts by mass. In parts by mass, the plant composition consists of 3 parts of celery seed extract, 5 parts of corn silk powder, 5 parts of pumpkin powder, 5 parts of lotus leaf powder, 3 parts of mulberry powder, and 3 parts of ginseng powder Mixed with 5 parts of grape powder.

Embodiment 3

[0049] A method for preparing solid particles of a plant composition, by mass percentage, the plant composition, auxiliary materials, isomalt, flavoring agent and essence are mixed uniformly, a 75wt% ethanol aqueous solution is used to prepare a soft material, and an 18-mesh sieve is used to prepare a soft material. Net granulation, drying at 45°C for 3 hours to obtain solid particles of plant composition, wherein, in parts by mass, the ratio of plant composition, auxiliary material, isomalt, flavoring agent and essence is 60:30:10: 0.3:0.1, the auxiliary materials are sorbitol and microcrystalline cellulose, and the ratio of sorbitol and microcrystalline cellulose is 20:10 in parts by mass. In parts by mass, the plant composition consists of 10 parts of celery seed extract, 10 parts of corn silk powder, 10 parts of pumpkin powder, 10 parts of lotus leaf powder, 10 parts of mulberry powder, and 10 parts of ginseng powder Mixed with 12 parts of grape powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com