Shield slurry dewatering apparatus

A dehydration device and mud technology, applied in the direction of water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of ignoring capillary water treatment, main engine wear, loud noise, etc., and achieve enhanced Improve the quality and efficiency of pore making, improve recycling and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

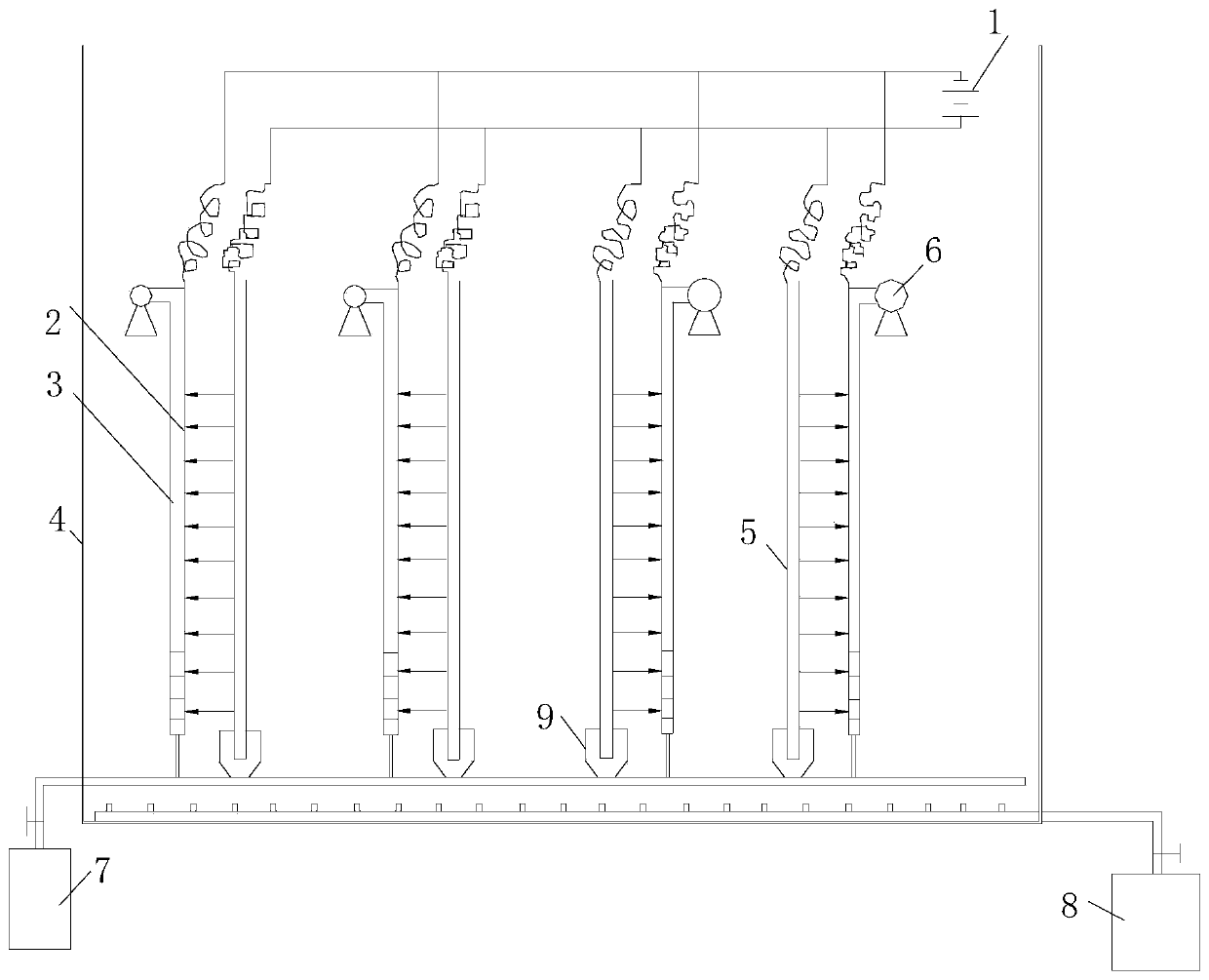

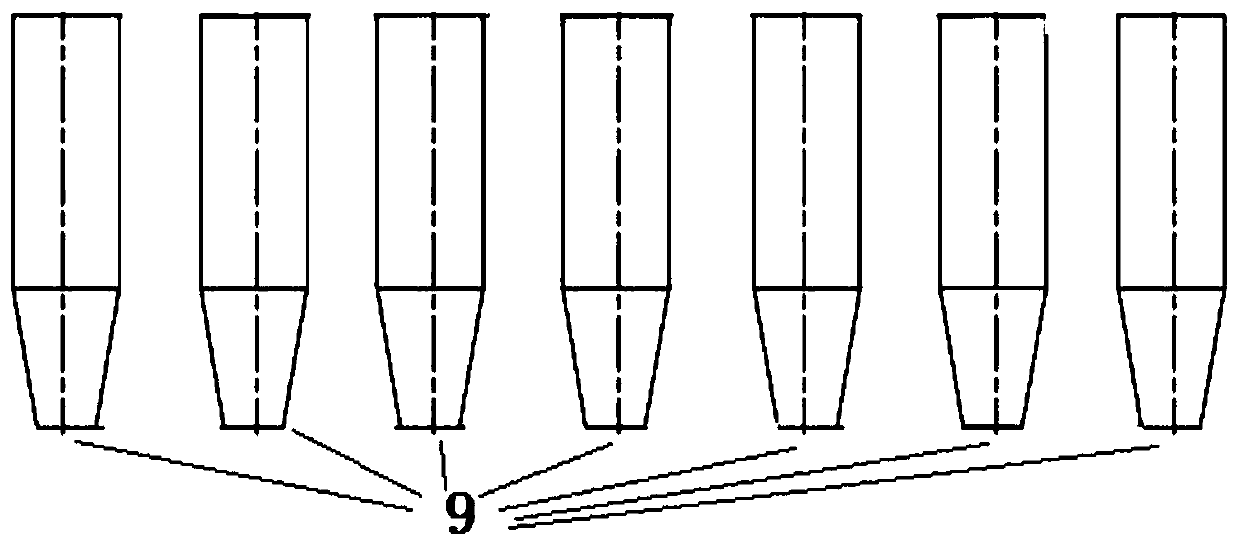

[0031] The present invention proposes a simple, effective, and low-cost shield mud dehydration device. The electrolysis-vacuum combined filtration mud dehydration is actually the separation of mud and water under the action of an electric field, and the obtained clarified filtrate is recycled. Therefore, the electrodialysis dehydration machine It mainly consists of a power supply 1, a cathode plate with holes 2 connected to the power supply 1, a flat ceramic membrane 3 adjacent to the cathode plate 2 with holes, a mud storage tank 4, an anode plate 5, a vacuum water collection device 6, a backwashing device 7, a blower Sweeping aeration device 8 and conical slot 9 for storing solid matter, the cathode plate with holes 2 is connected to the negative pole of the power supply 1, and the anode plate 5 is connected to the positive pole of the power supply 1; the flat ceramic membrane 3 and the cathode plate with holes 2 form together The cathode membrane, the upper end of the flat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com