Method for preparing near-infrared responsive functional coating on surface of cylindrical titanium nail and application

A near-infrared, cylindrical technology, applied in the direction of coatings, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve problems such as limited growth, and achieve no impact on the environment, low cost, good photocatalytic performance and photothermal performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

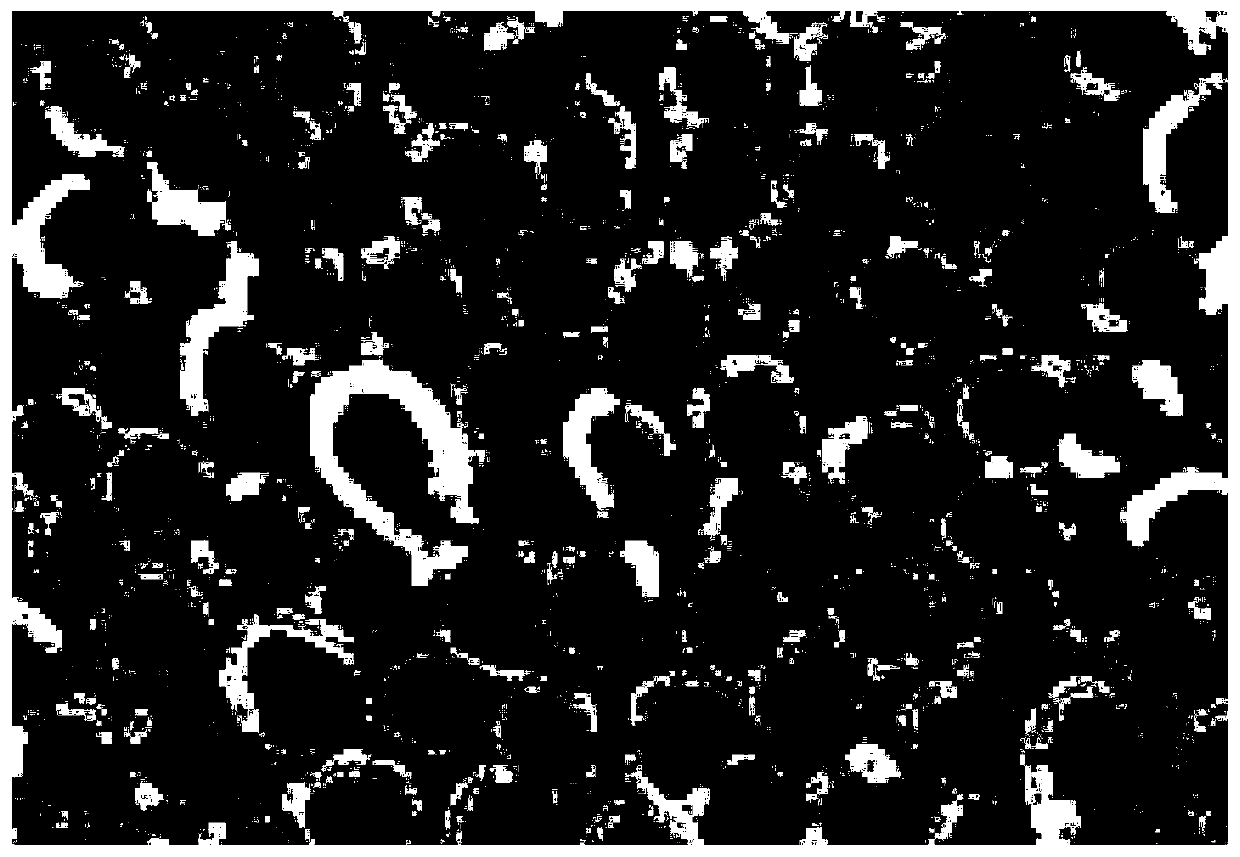

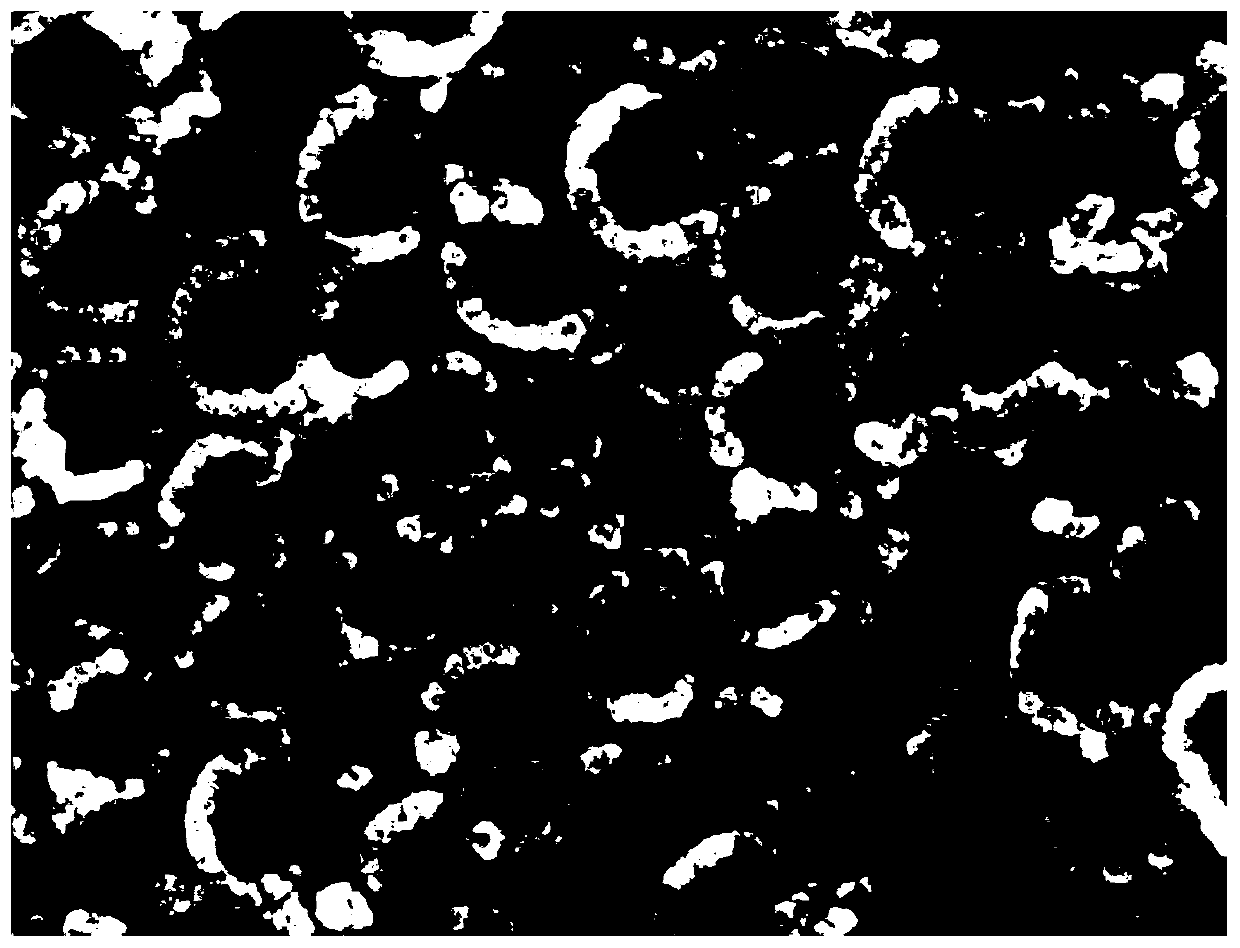

Image

Examples

Embodiment 1

[0035] (1) Polish metal cylinder titanium nails with a diameter of 1mm and a length of 6mm with 240 mesh, 400 mesh, 600 mesh, 800 mesh and 1200 mesh sandpaper until the surface is smooth, then put them into a beaker and add acetone, ethanol and deionized water in turn Ultrasonic cleaning was performed to remove impurities on the surface of the titanium nails, and then dried under vacuum at 50°C for 12 hours.

[0036] (2) Mix 1mL hydrofluoric acid, 4mL nitric acid and 5mL deionized water to prepare an etching solution, immerse the polished titanium nail in the etching solution for 2 minutes, take out the titanium nail and clean it with deionized water, and then soak it in ethanol . 10mg / mL polystyrene ethanol

[0037] (3) Preparation of titanium dioxide nanotubes on the surface of titanium nails: Dissolve 0.34g of ammonium fluoride into 5mL of deionized water, add the ammonium fluoride solution to 95mL of ethylene glycol solution to prepare an electrolyte, and then treat the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com