Bismuth/bismuth oxide/sodium tantalum oxide composite material for treating hexavalent chromium ion wastewater and preparation method of composite material

A technology of hexavalent chromium ion and composite material, which is applied in the field of bismuth/bismuth oxide/sodium tantalate composite material and its preparation, can solve problems such as low catalytic activity, and achieve the effects of simple process, increased cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

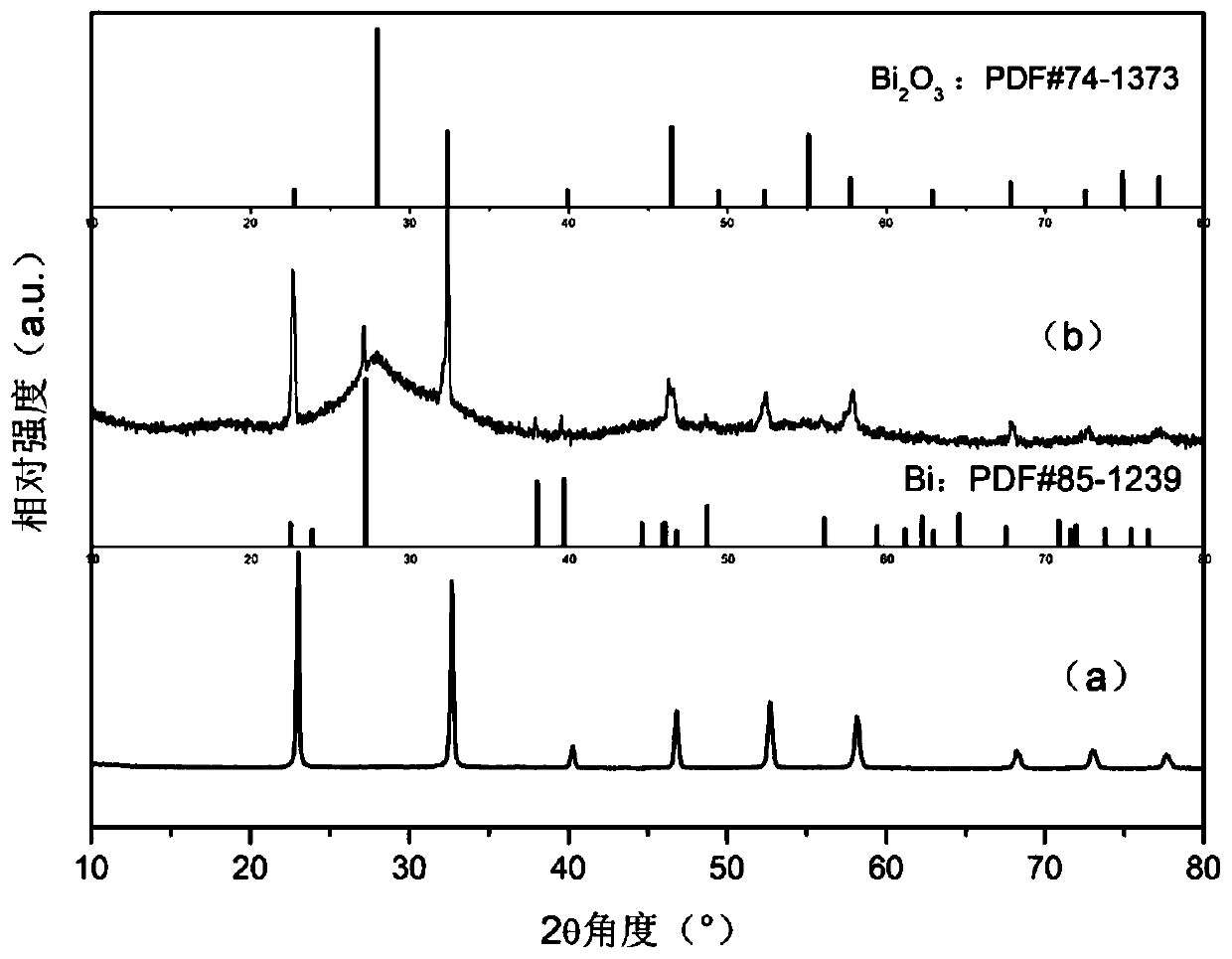

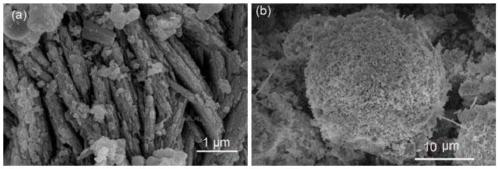

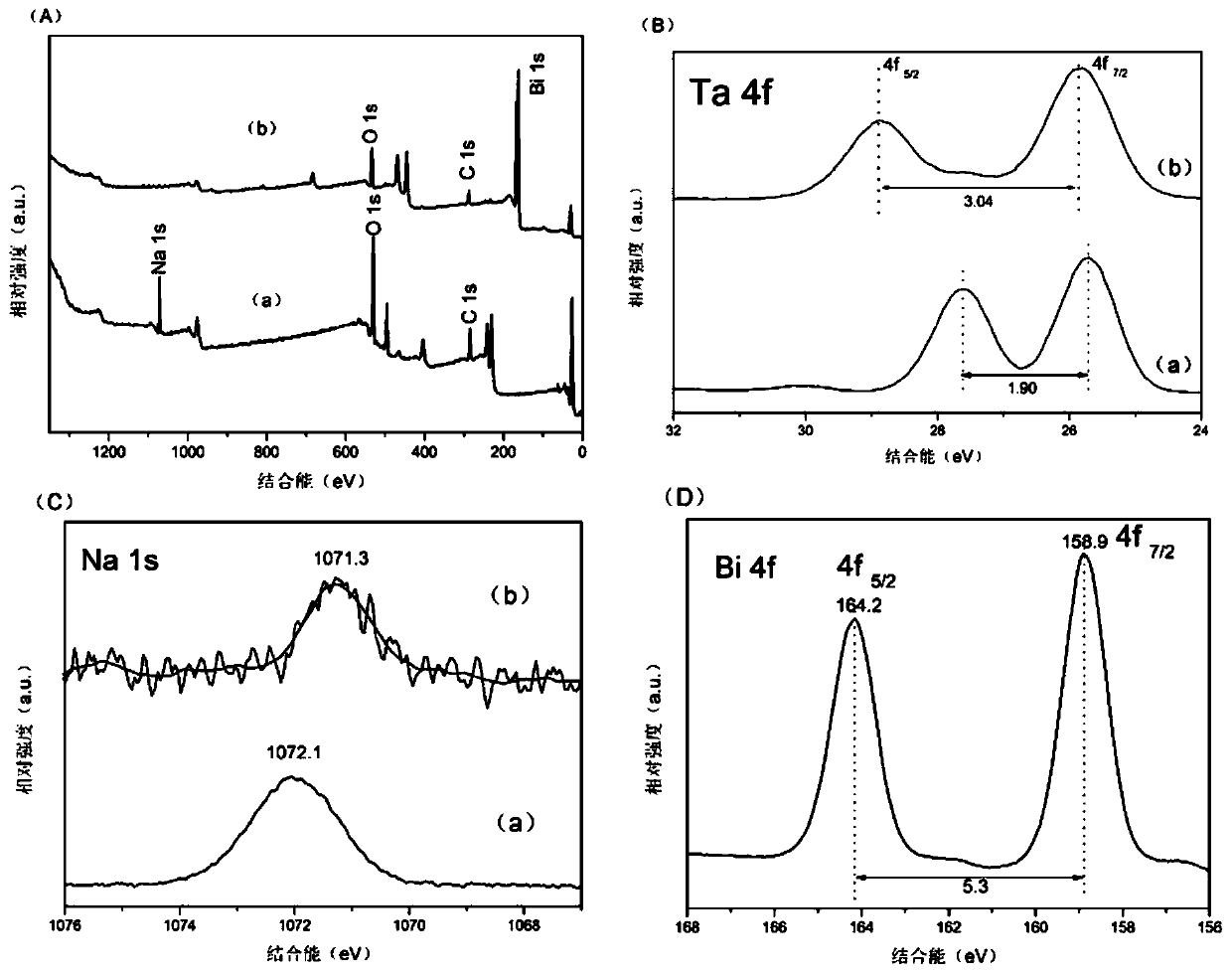

[0032] A preparation method for bismuth / bismuth oxide / sodium tantalate composite material for treating hexavalent chromium ion wastewater, said method comprising the following steps:

[0033] (1) Synthesis of NaTaO by hydrothermal synthesis 3 : Weigh 24 g of NaOH and then add 60 mL of deionized water to prepare a 10 mol / L NaOH solution, then add 0.2 g of Ta 2 o 5 (At this time NaOH and Ta 2 o 5 The mass ratio is 120:1) placed on a magnetic stirrer and stirred for 1 h to make it fully mixed, poured the mixed solution into the polytetrafluoroethylene lining and put it into a hydrothermal reaction kettle, at a temperature of 160°C After the reaction was completed, it was washed with deionized water for 3 times and ethanol for 2 times, and dried at 60°C to obtain NaTaO 3 ;

[0034] (2) Preparation of Bi / Bi by hydrothermal synthesis 2 o 3 / NaTaO 3 Photocatalyst: 41.2 mg of NaTaO 3 and 196 mg of Bi(NO 3 ) 3 ·5H 2 O (at this time Bi(NO 3 ) 3 ·5H 2 O and NaTaO 3 The ma...

Embodiment 2

[0037] A preparation method for bismuth / bismuth oxide / sodium tantalate composite material for treating hexavalent chromium ion wastewater, said method comprising the following steps:

[0038] (1) Synthesis of NaTaO by hydrothermal synthesis 3 : Weigh 20g of NaOH and then add 60 mL of deionized water to prepare a 10 mol / L NaOH solution, then add 0.2g of Ta 2 o 5 (At this time NaOH and Ta 2 o 5 The mass ratio is 100:1) placed on a magnetic stirrer and stirred for 1 h to make it fully mixed, poured the mixed solution into the liner of polytetrafluoroethylene and put it into a hydrothermal reaction kettle, at a temperature of 160 °C After the reaction was completed, it was washed with deionized water for 3 times and ethanol for 2 times, and dried at 60°C to obtain NaTaO 3 .

[0039] (2) Preparation of Bi / Bi by hydrothermal synthesis 2 o 3 / NaTaO 3 Composite material: 41.2 mg of NaTaO 3 and 164.8mg of Bi(NO 3 ) 3 ·5H 2 O (at this time Bi(NO 3 ) 3 ·5H 2 O and NaTaO ...

Embodiment 3

[0042] A preparation method for bismuth / bismuth oxide / sodium tantalate composite material for treating hexavalent chromium ion wastewater, said method comprising the following steps:

[0043] (1) Synthesis of NaTaO by hydrothermal synthesis 3 : Weigh 28g of NaOH and then add 60 mL of deionized water to prepare a 10 mol / L NaOH solution, then add 0.2g of Ta 2 o 5 (At this time NaOH and Ta 2 o 5 The mass ratio is 140:1) placed on a magnetic stirrer and stirred for 1 h to make it fully mixed. Pour the mixed solution into a polytetrafluoroethylene lining and put it in a hydrothermal reaction kettle. After the reaction was completed, it was washed with deionized water for 3 times and ethanol for 2 times, and dried at 60°C to obtain NaTaO 3 .

[0044] (2) Preparation of Bi / Bi by hydrothermal synthesis 2 o 3 / NaTaO 3 Composite material: 41.2 mg of NaTaO 3 and 247.2mg of Bi(NO 3 ) 3 ·5H 2 O (at this time Bi(NO 3 ) 3 ·5H 2 O and NaTaO 3 The mass ratio of 6:1) was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com