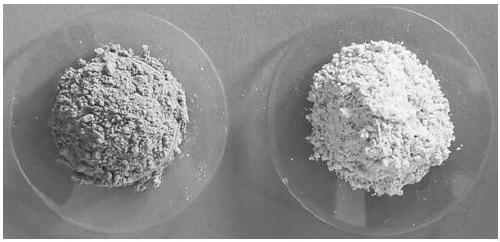

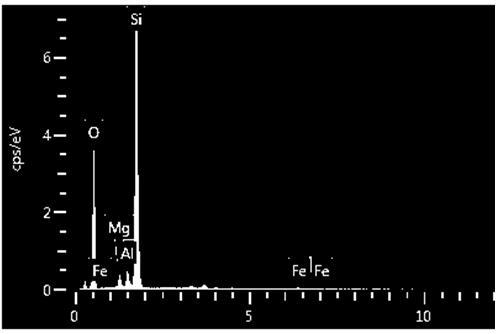

Method for preparing white mixed nanometer silicon material by using red attapulgite clays

A technology of attapulgite clay and nano-silicon, which is applied in the field of preparation of white nano-silicon materials, can solve the problems of high energy consumption, many technological processes, and difficulty in reaching nanoscale products, and achieve the effect of good whiteness of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Spray 17.5kg of 30% (mass fraction) sulfuric acid aqueous solution evenly into 50kg of red attapulgite clay mineral powder (attapulgite content: 49%), mix well, and press it into thin slices with a thickness of 0.8mm, and then Put it under the condition of 100℃ for 24h to complete the preactivation. Then, disperse the pre-activated attapulgite clay into 1000kg0.5mol / L oxalic acid solution, then add 2.5kg orthosilicic acid to it, stir and mix evenly, then reflux at 100°C for 4h, and cool the obtained suspension , under the pressure of 50MPa, carry out high-pressure homogenization treatment, add 5g of orthosilicic acid to it, heat and activate it under reflux at 80°C for 24h, then carry out high-pressure homogenization treatment on the suspension at 30MPa, and finally centrifuge the suspension, and the solid product is re- After washing, drying and pulverizing, a white nano silicon oxide material is obtained. CIE- L*,a*,b* See Table 2 for color values.

Embodiment 2

[0032] Spray 17.5kg of 30% (mass fraction) phosphoric acid aqueous solution evenly into 50kg of red attapulgite clay mineral powder (attapulgite content 20%). Put it under the condition of 120℃ for 12h to complete the preactivation. Then, disperse the pre-activated attapulgite clay into 250kg5mol / L citric acid solution, then add 10kg orthosilicic acid to it, stir and mix evenly, then reflux at 100°C for 12h, cool the obtained suspension, and Under 5MPa pressure, high-pressure homogeneous treatment is carried out, and finally the suspension is centrifuged, and the solid product is washed, dried, and pulverized to obtain a white nano-silicon oxide material. CIE- L*,a*,b* See Table 2 for color values.

Embodiment 3

[0034]Spray 20kg of 20% (mass fraction) hydrochloric acid aqueous solution evenly into 50kg of red attapulgite clay mineral powder (attapulgite content: 40%), mix well, and press it into thin slices with a thickness of 0.8mm, and then Put it under the condition of ℃ for 24h to complete the pre-activation. Then, disperse the pre-activated attapulgite clay into 500kg2mol / L succinic acid solution, then add 5kg of orthosilicic acid to it, stir and mix evenly, then reflux at 60°C for 24h, and cool the obtained suspension, Under the pressure of 30MPa, high-pressure homogeneous treatment is carried out, and finally the suspension is centrifuged, and the solid product is washed, dried and pulverized to obtain a white nano-silicon oxide material. CIE- L*, a*, b* See Table 2 for color values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com