A kind of polyimide aerogel with petal effect and its preparation method and application

A polyimide gel and polyimide technology, which is applied in the fields of nanoporous materials and thermal insulation, can solve the problems of low output, low temperature resistance performance, loss of mechanical strength, etc., and achieve low thermal conductivity. , Huge application prospect, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned polyimide airgel with a petal effect, which includes:

[0041] Polymerize the mixed system containing acid anhydride monomer, diamine and solvent to form polyamic acid;

[0042]A chemical dehydrating agent is added to the mixed system, and then the polyimide gel is formed by standing still, and then aged, solvent replaced and dried to obtain the polyimide airgel with petal effect.

[0043] In some implementation cases, the preparation method specifically includes:

[0044] Add a certain amount of acid anhydride monomer into the diamine solution, stir and polymerize for a certain period of time to form a very dilute polyamic acid solution, forming a mixed system;

[0045] A chemical dehydrating agent is added to the mixed system, and then the polyimide gel is formed by standing still, and after aging and solvent replacement, it is dried by supercritical flu...

Embodiment 1

[0069] (1) Synthesis of polyamic acid: Dissolve 10mg of 4,4'-diaminodiphenyl ether in 100ml of N-methylpyrrolidone, stir and dissolve, then add 4,4'-biphenyl with 90% moles of the aforementioned diamine After ether dianhydride was stirred at 10°C for 10 h until it was completely dissolved, a dilute solution of polyamic acid was obtained.

[0070] (2) Synthesis of polyimide gel: Add 20 g of acetic anhydride / triethylamine (molar ratio: 1:1) mixture to the above polyamic acid mixture, stir rapidly for 10 minutes, and ultrasonically degas for 30 minutes. minute. Finally, the obtained solution was left standing at 10° C., and a polyimide gel was formed after 5 hours.

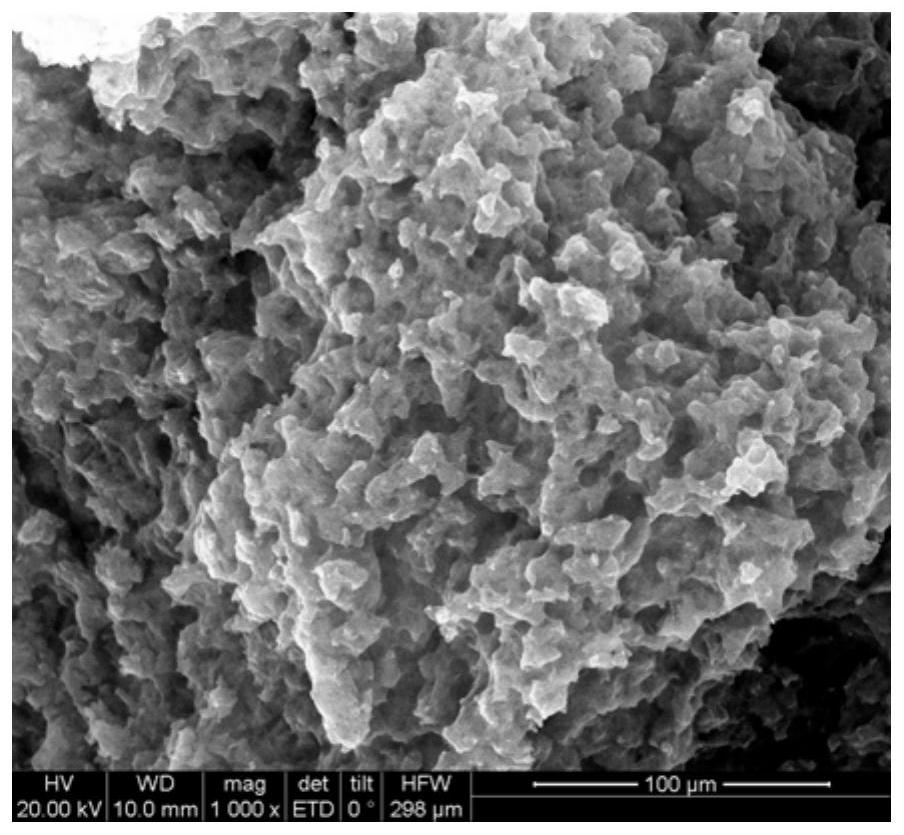

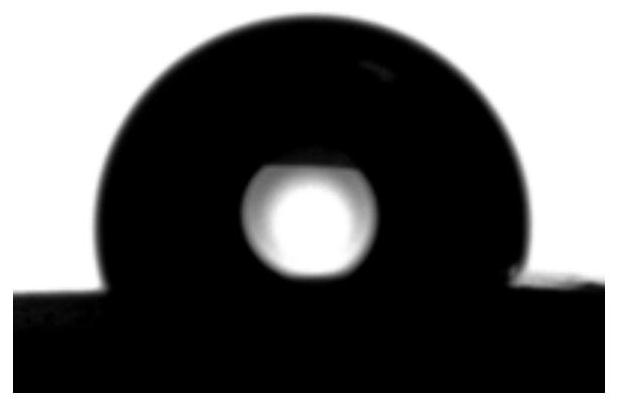

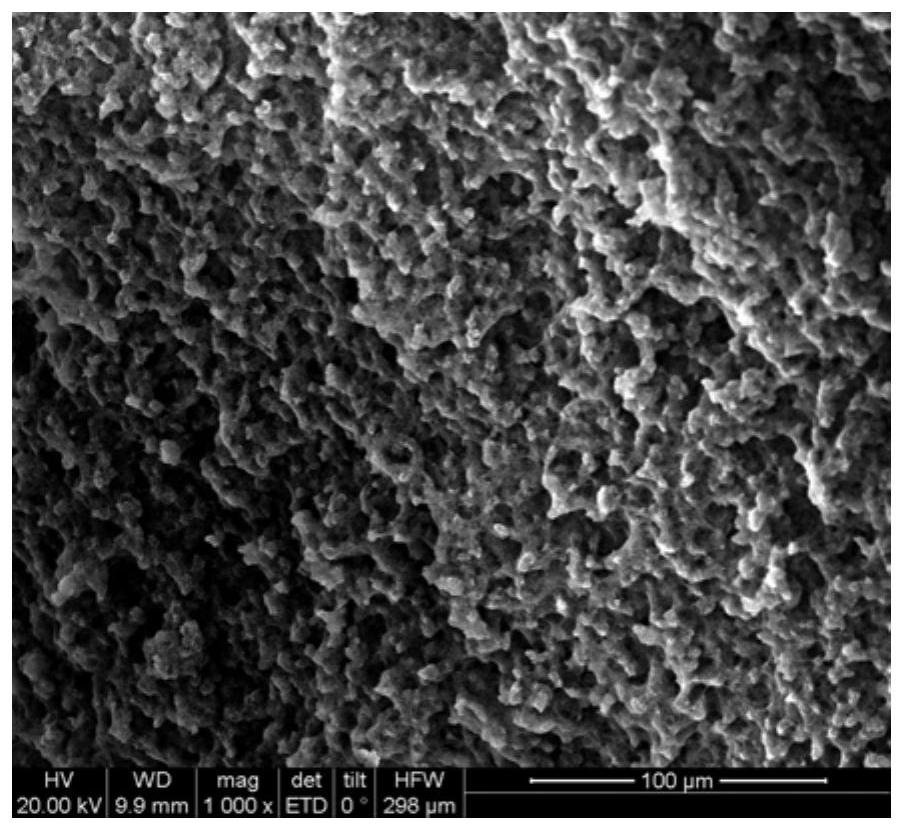

[0071] (3) Preparation of polyimide airgel with petal effect: put the above polyimide gel at 80°C for aging for 24 hours, then soak it in 100g of N-methylpyrrolidone for 12 hours, and then replace it with 200g of acetone Twice, 12 hours each time, and finally dry the replaced polyimide gel with supercritical carbon...

Embodiment 2

[0073] (1) Synthesis of polyamic acid: Dissolve 2 mg of 9,9-bis(4-aminophenyl)fluorene in 100 ml of dimethyl sulfoxide, stir and dissolve, then add 4,4'- After diphenyl ether dianhydride was stirred at 20°C for 8 hours until it was completely dissolved, a dilute solution of polyamic acid was obtained.

[0074] (2) Synthesis of polyimide gel: Add 5 g of acetic anhydride / pyridine (1:1 molar ratio) mixture into the dilute polyamic acid solution, stir rapidly for 20 minutes, and ultrasonically degas for 20 minutes. Finally, the obtained solution was left standing at 30° C., and a polyimide gel was formed after 3 hours.

[0075] (3) Preparation of polyimide airgel with petal effect: put the above polyimide gel at 60°C for aging for 24 hours, then soak it in 150g of N-methylpyrrolidone for 12 hours, and then replace it with 100g of acetone Twice, each time for 12 hours, and finally the replaced polyimide gel was dried with supercritical ethanol, the drying temperature was 100°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com