High-efficiency water reducer

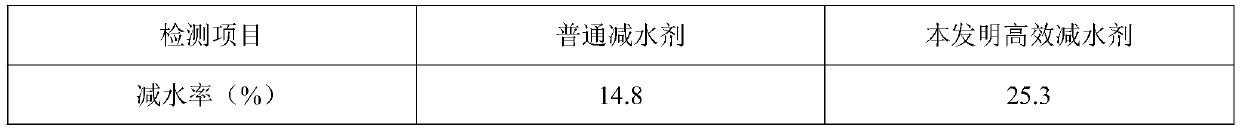

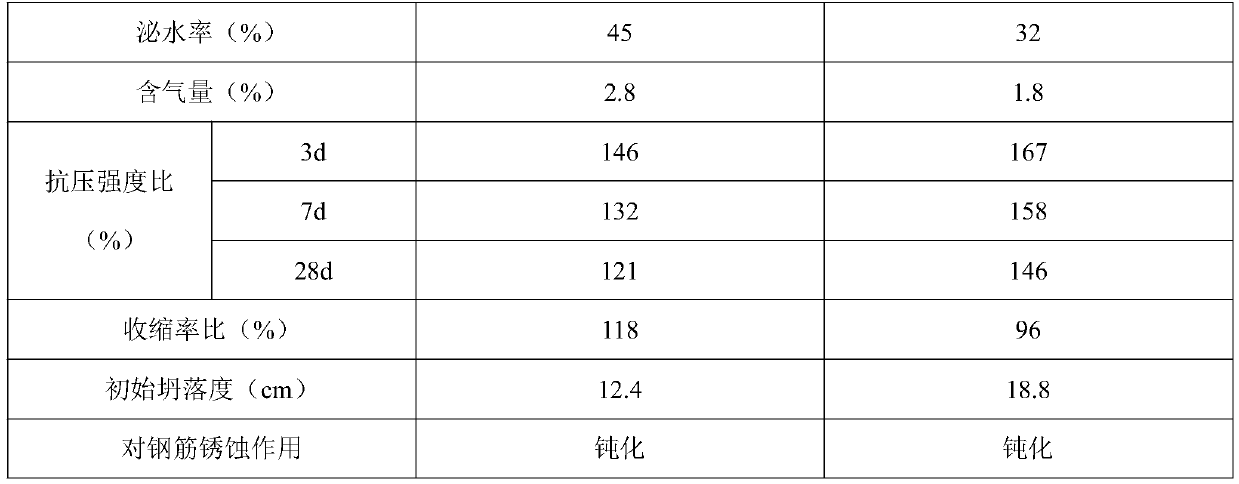

A high-efficiency water-reducing agent and additive technology, applied in the field of concrete admixtures, can solve the problems of inability to meet concrete performance requirements, low water-reducing rate, poor fluidity, etc., and achieve improved fluidity and workability, high water-reducing rate, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] A high-efficiency water reducer, which is made by mixing the following raw materials in parts by weight: β-naphthalene sulfonate formaldehyde condensate 45-65, polyethylene glycol monomethyl ether methacrylate 15-25, calcium lignosulfonate 20-30, ethylene oxide-propylene oxide copolymer 15-20, trehalose 3-5, silicone powder 1.8-2.8, shale ash 3-7, sodium bisulfite 3-5, polyethylene oxide 4.5 -9.5, aluminum tripolyphosphate 7-13, cocoyl diethanolamine 2.5-3.5, barium dinonylnaphthalene sulfonate 1.5-2.5, urotropine 2.5-3.5, additives 2.5-5.5.

[0015] β-naphthalene sulfonate formaldehyde condensate 50, polyethylene glycol monomethyl ether methacrylate 20, calcium lignosulfonate 25, ethylene oxide-propylene oxide copolymer 18, trehalose 4, silicone powder 2. Shale ash 5, sodium bisulfite 4, polyethylene oxide 7, aluminum tripolyphosphate 10, cocoamide diethanolamine 3, barium dinonyl naphthalene sulfonate 2, urotropine 3, additive 4.

[0016] The auxiliary agent is made ...

specific Embodiment

[0021] Specific embodiment: a kind of high-efficiency water reducing agent is formed by mixing the raw materials of the following weight (Kg): β-naphthalene sulfonate formaldehyde condensate 50, polyethylene glycol monomethyl ether methacrylate 20, lignin sulfonate Calcium acid 25, ethylene oxide-propylene oxide copolymer 18, trehalose 4, silicone powder 2, shale ash 5, sodium bisulfite 4, polyethylene oxide 7, aluminum tripolyphosphate 10, cocoyl Diethanolamine 3, barium dinonyl naphthalene sulfonate 2, urotropine 3, additive 4.

[0022] The auxiliary agent is made of the following raw materials in parts by weight: 9-14 magnesite, 2-5 magnesium humate, 2.5-4.5 ammonium benzoate, 5.5-11.5 sodium α-alkenyl sulfonate, phytic acid Ester 2-3, Isobutylene Triethoxysilane 2.5-5.5, Polyferric Chloride 4-9, Germanium Stone Powder 11-17, Titanium Dioxide 4-10, Myristyl Glucoside 1-3, Polyamide Wax 3-6 , lithium magnesium silicate 2-4, tea saponin 1-3.

[0023] The preparation steps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com