Composite door and window grouting mortar and use method thereof

A composite, door and window technology, applied in the direction of construction, building structure, etc., can solve the problems of difficult control of construction quality, great influence on the storage stability of single-component adhesive, and incompact filling of foaming agent, etc., and achieves good reinforcement ability. and anti-deformation ability, excellent tensile bonding ability, shorten the construction period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

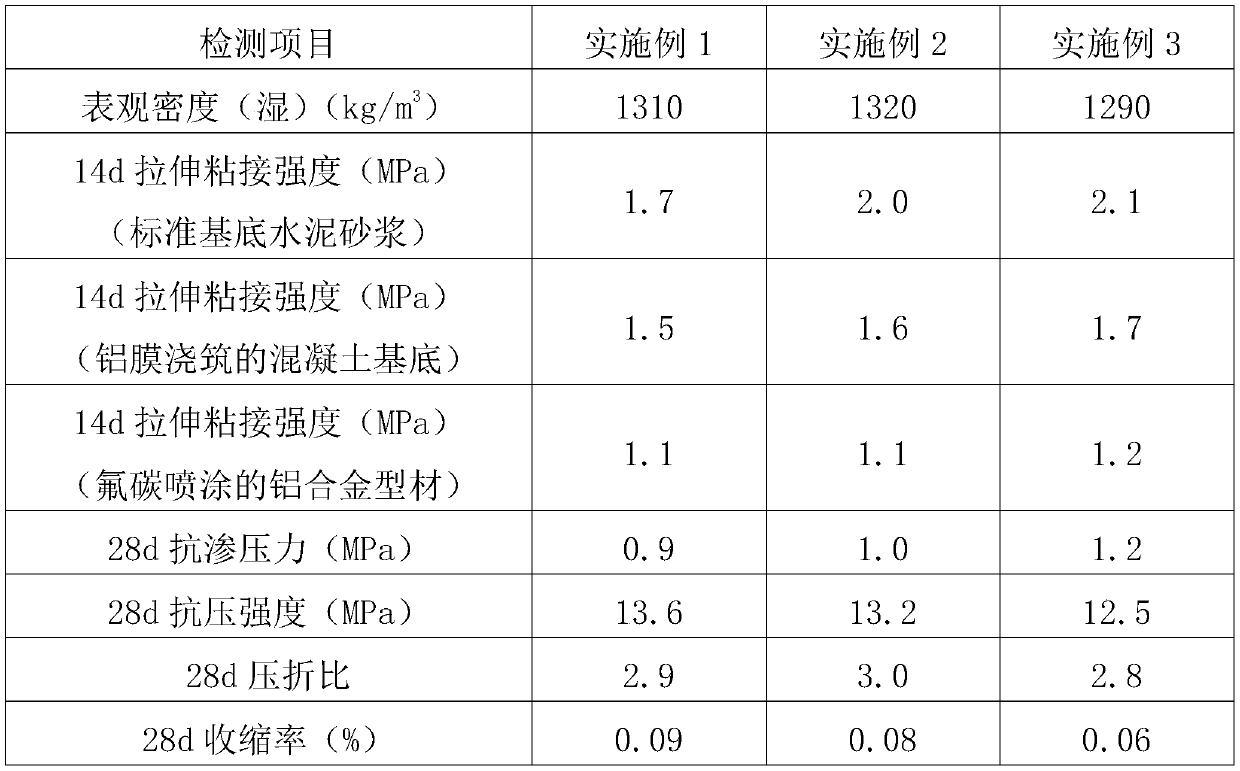

Embodiment 1

[0046] A composite door and window caulking mortar, including powder and liquid materials,

[0047] The powder includes the following components in parts by weight: 65 parts of 42.5 grade ordinary Portland cement, 25 parts of II grade fly ash, 10 parts of calcium oxide, 0.2 parts of anti-shrinkage agent, 3.9 parts of polystyrene particles, hydroxyl 0.3 part of propyl methyl cellulose, 0.3 part of sheet silicate mineral material, 0.2 part of silicone waterproofing agent, and 0.2 part of melamine water reducing agent.

[0048] The liquid material includes the following components in parts by weight: 20 parts of vinyl acetate-ethylene copolymer emulsion, 2 parts of styrene-butadiene emulsion, 0.1 part of defoamer, 0.05 part of dispersant, 0.03 part of bacteriostatic agent, and 60 parts of water;

[0049] The mass ratio of the powder material to the liquid material is 1:0.35.

[0050] The method for using the composite door and window caulking mortar includes the following steps:...

Embodiment 2

[0053] A composite door and window caulking mortar, including powder and liquid materials,

[0054] The powder includes the following components in parts by weight: 55 parts of 42.5 grade ordinary Portland cement, 15 parts of II grade fly ash, 10 parts of granulated blast furnace slag powder, 5 parts of magnesium oxide, 11 parts of gypsum, anti-shrinkage 0.3 parts of agent, 3 parts of polystyrene particles, 0.2 parts of hydroxypropyl methylcellulose, 0.4 parts of sheet silicate mineral material, 0.3 parts of silicone waterproofing agent, and 0.3 parts of polycarboxylate water reducing agent.

[0055] The liquid material includes the following components in parts by weight: 22 parts of vinyl acetate-ethylene copolymer emulsion, 4 parts of polyacrylate emulsion, 0.5 part of defoamer, 0.6 part of dispersant, 0.2 part of bacteriostatic agent, 70 parts of water ;

[0056] The mass ratio of the powder material to the liquid material is 1:0.45.

[0057] The method for using the com...

Embodiment 3

[0060] A composite door and window caulking mortar, including powder and liquid materials,

[0061] The powder includes the following components in parts by weight: 60 parts of 42.5 grade ordinary Portland cement, 18 parts of granulated blast furnace slag powder, 5 parts of calcium oxide, 6 parts of magnesium oxide, 0.4 part of anti-shrinkage agent, polystyrene 4.8 parts of granule, 0.1 part of hydroxypropyl methylcellulose, 0.5 part of sheet silicate mineral material, 0.4 part of silicone waterproofing agent, and 0.05 part of polycarboxylate superplasticizer.

[0062] The liquid material includes the following components in parts by weight: 25 parts of vinyl acetate-ethylene copolymer emulsion, 6 parts of styrene-butadiene emulsion, 4 parts of polyacrylate emulsion, 0.3 part of defoamer, 0.3 part of dispersant, antibacterial agent 0.1 part, 68 parts of water;

[0063] The mass ratio of the powder material to the liquid material is 1:0.40.

[0064] The method for using the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com