A slurry for photocuring 3D printing ceramics and a method for preparing ceramic products thereof

A technology of 3D printing and light-curing materials, applied in the field of ceramic 3D printing, can solve the problems of high organic content of photosensitive resin, high cost of raw materials, environmental pollution, etc., and achieve the effect of simple and effective preparation method, good fluidity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Preferably, the ceramic product preparation method using the slurry for photocuring 3D printing ceramics comprises the following steps:

[0058] Step A, according to the mass percentage, mix 70-85% ceramic powder, 10-25% light-curing material and 4-10% additives and ball mill for 20-60 minutes to obtain a volume solid content of 40-60%. slurry;

[0059] Step B, put the slurry mixed in step A into a high-speed vacuum agitator to evacuate and stir for 20-40 min to prepare a slurry for photocuring 3D printing ceramics;

[0060] Step C, putting the vacuum-stirred slurry in Step B into a light-curing 3D printer for 3D printing and molding to obtain a green body;

[0061] Step D, cleaning up excess slurry on the green body prepared in step C, and then drying;

[0062] Step E, debinding and sintering the dried green body in step D to obtain a ceramic product.

[0063] Using the ceramic product preparation method for photocuring 3D printing ceramic slurry can save the time a...

Embodiment 1~6

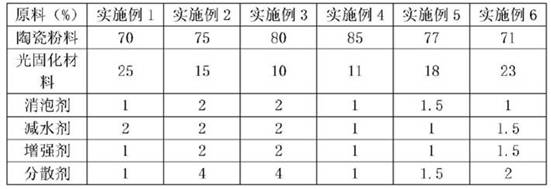

[0078] Examples 1-6 Weigh each raw material according to Table 1 to Table 5 according to mass percentage.

[0079]

[0080] Table 1

[0081]

[0082] Table 2

[0083]

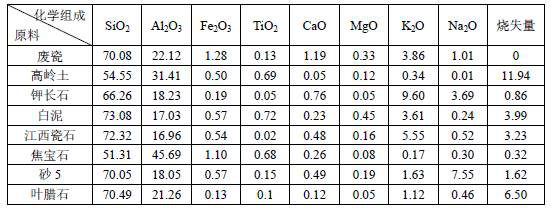

[0084] table 3

[0085]

[0086] Table 4

[0087]

[0088] table 5

[0089] Embodiments 1-6 prepare the slurry for photocuring 3D printing ceramics and ceramic products thereof according to the following steps:

[0090] Preparation of ceramic powder

[0091] Step A1, put waste porcelain, white clay, potassium feldspar, sand 5, Jiangxi porcelain stone, kaolin, pyrophyllite and burnt gem into the ball mill jar, and simultaneously put deionized water, lignin, sodium metasilicate and Coupling agent K-560, and then rapid wet ball milling for 30 minutes to prepare ceramic slurry;

[0092] In step A2, the ceramic slurry prepared in step A1 is dried, and then dry-method rapid ball milled for 3 minutes, and the obtained powder is passed through a 100-mesh sieve and stored for later use.

[0093] Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com