Liquid fertilizer and preparation method thereof

A liquid fertilizer and liquid technology, applied in the field of liquid fertilizer and its preparation, can solve the problems of slow absorption and transportation of plant nutrients, insignificant improvement of crop yield and quality, and insignificant effect of plant growth, etc., so as to promote absorption and transportation. , reduce crop diseases and insect pests, assist the effect of nitrogen fixation by aerial roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

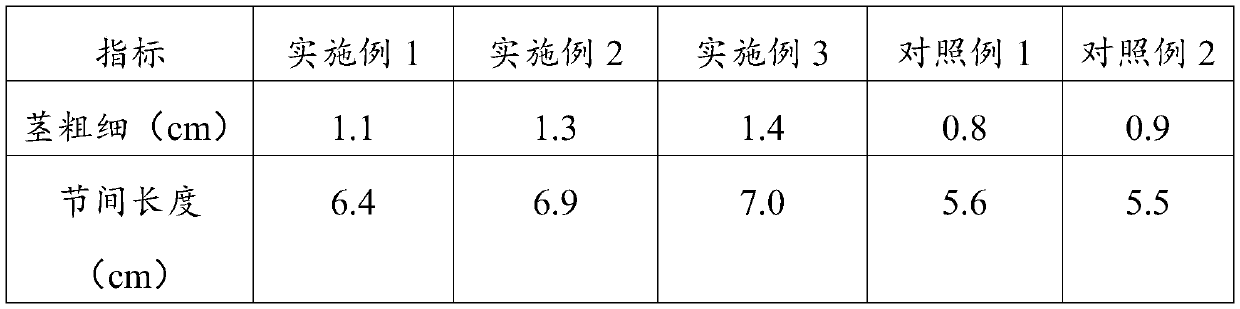

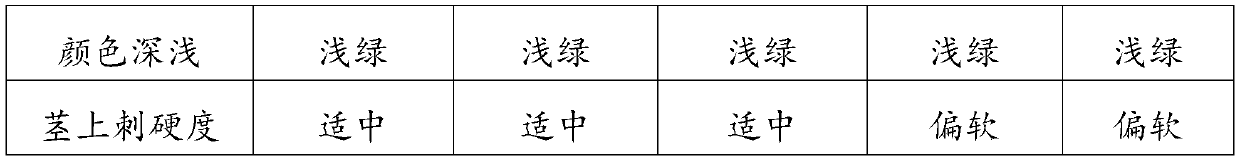

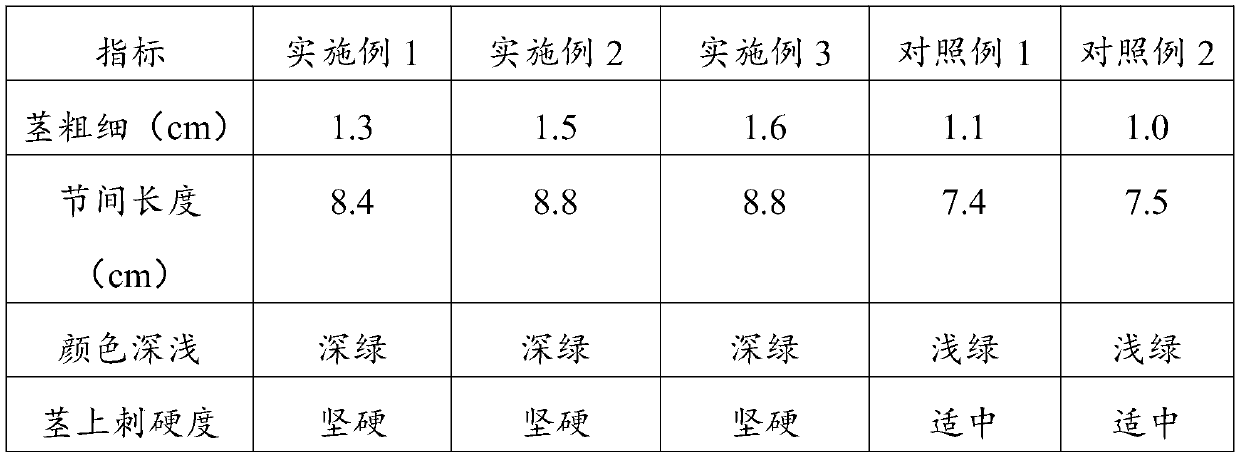

Embodiment 1

[0025] According to 5 parts of purified water, 5 parts of 75% phosphoric acid, 0.5 parts of wood vinegar, 0.5 parts of bitter soil, 0.5 parts of CORE fertilizer additives, 0.5 parts of liquid gluconic acid, 0.5 parts of liquid malic acid, 0.5 parts of rare earth elements, and 0.5 parts of amino acid raw powder 0.5 parts, complex titanium 0.5 parts, sodium decaborate 0.5 parts, calcium nitrate 0.5 parts, magnesium nitrate 0.5 parts, EDTA copper 0.005 parts, EDTA manganese 0.005 parts, EDTA zinc 0.005 parts, iron acetate 0.005 parts, cobalt nitrate 0.005 parts, nitric acid 0.005 parts of nickel, 0.005 parts of ammonium molybdate, 0.005 parts of potassium acetate, 5 parts of liquid potassium formate, 5 parts of potassium thiosulfate, 0.005 parts of vitamins, 5 parts of liquid potassium silicate, 5 parts of urea ammonium nitrate solution, 0.005 parts of Heconol part, 0.005 part of sodium salicylate and 0.05 part of polyglutamic acid in the ratio and order of adding and stirring uni...

Embodiment 2

[0027] According to 30 parts of purified water, 20 parts of 75% phosphoric acid, 2 parts of wood vinegar, 2 parts of bitter soil, 2 parts of CORE fertilizer additive, 2 parts of liquid gluconic acid, 2 parts of liquid malic acid, 2 parts of rare earth elements, and 2 parts of raw amino acid powder 2 parts, complex titanium 2 parts, sodium decaborate 2 parts, calcium nitrate 2 parts, magnesium nitrate 2 parts, EDTA copper 0.05 parts, EDTA manganese 0.05 parts, EDTA zinc 0.05 parts, iron acetate 0.05 parts, cobalt nitrate 0.05 parts, nitric acid 0.05 parts of nickel, 0.05 parts of ammonium molybdate, 0.05 parts of potassium acetate, 10 parts of liquid potassium formate, 10 parts of potassium thiosulfate, 0.05 parts of vitamins, 10 parts of liquid potassium silicate, 25 parts of urea ammonium nitrate solution, 0.05 parts of Hekangsu part, 0.05 part of sodium salicylate and 0.2 part of polyglutamic acid were added in sequence and stirred evenly to obtain a liquid fertilizer.

Embodiment 3

[0029] 20 parts of purified water, 12 parts of 75% phosphoric acid, 1.2 parts of wood vinegar, 1.2 parts of bitter soil, 1.2 parts of CORE fertilizer additive, 1.2 parts of liquid gluconic acid, 1.2 parts of liquid malic acid, 1.5 parts of rare earth elements, and 1.5 parts of amino acid raw powder 1.5 parts of titanium complex, 1.5 parts of sodium decaborate, 1.5 parts of calcium nitrate, 1.5 parts of magnesium nitrate, 0.025 parts of copper EDTA, 0.025 parts of manganese EDTA, 0.025 parts of zinc EDTA, 0.025 parts of iron acetate, 0.025 parts of cobalt nitrate, nitric acid 0.025 parts of nickel, 0.025 parts of ammonium molybdate, 0.025 parts of potassium acetate, 7.5 parts of liquid potassium formate, 7.5 parts of potassium thiosulfate, 0.025 parts of vitamins, 7.5 parts of liquid potassium silicate, 15 parts of urea ammonium nitrate solution, and 0.025 parts of Hekangsu part, 0.025 part of sodium salicylate and 0.1 part of polyglutamic acid were added in sequence and stirred...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap