Fracturing fluid thickener and preparation method thereof

A fracturing fluid thickener and emulsifier technology, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of poor low temperature solubility, inability to meet real-time mixing on site, affecting the stimulation effect of fracturing, etc. , to achieve the effect of improving high temperature resistance, improving system viscosity and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

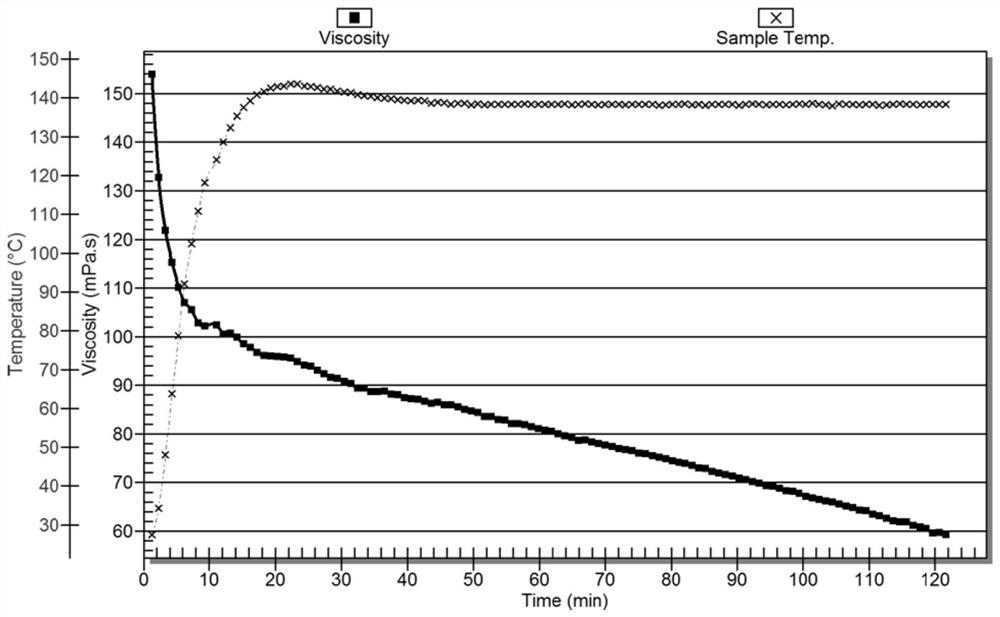

Image

Examples

preparation example Construction

[0043] The invention provides a preparation method of a fracturing fluid thickener, comprising:

[0044] Add acrylamide, acrylic monomer, 2-acrylamido-2-methylpropanesulfonic acid, salt-resistant monomer and For the temperature-resistant monomer, add 80%-200% deionized water accounting for the mass of the monomer and adjust the pH to 6-8 with 30% NaOH solution, and then add an aqueous emulsifier accounting for 1-10% of the monomer mass and stir to dissolve uniform;

[0045] Add white oil containing an oily emulsifier to emulsify for 10-30 minutes under stirring, the oily emulsifier accounts for 1-8% of the monomer mass, and the white oil accounts for 70-200% of the monomer mass; after emulsification, feed Deoxygenation with high-purity nitrogen for 30-40 minutes; control the initiation temperature at 0-10°C, add a redox initiator and an azo initiator for polymerization reaction, and obtain a water-in-oil inverse emulsion after reacting for 3-8 hours;

[0046] An aqueous emul...

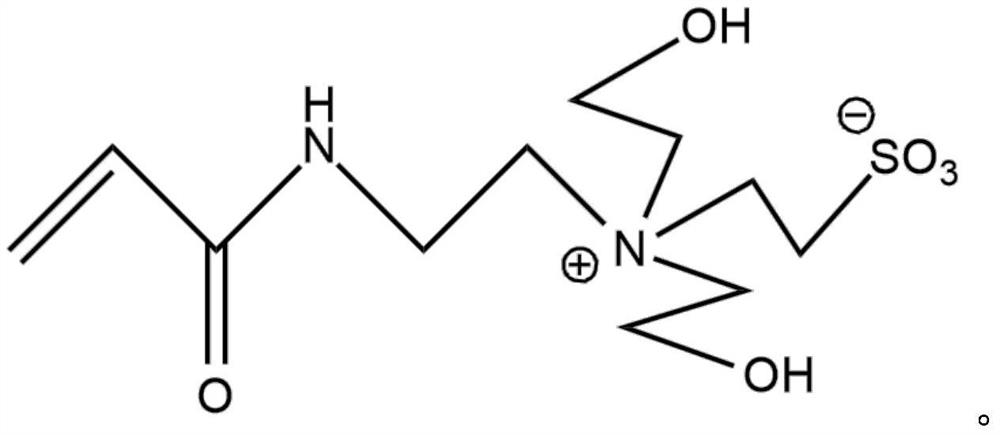

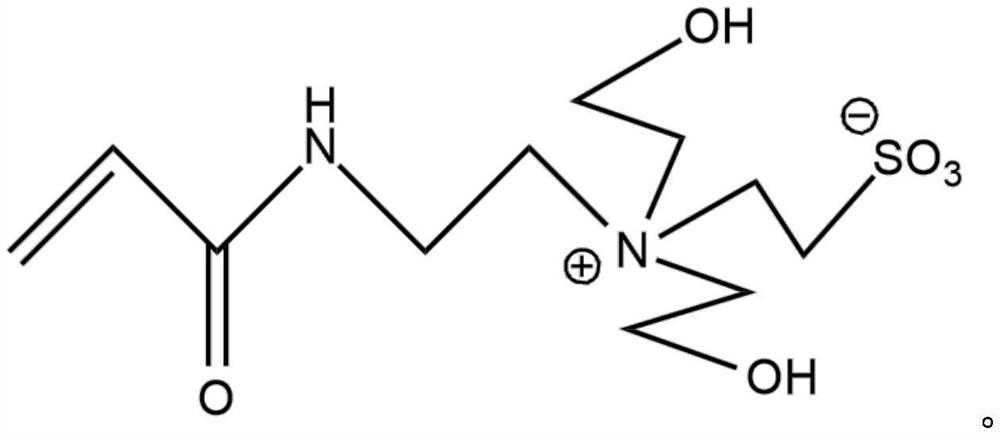

Embodiment 1

[0051] Put 55g of N-(2-aminoethyl)-acrylamide and 100ml of butanone into a 500mL pressure vessel, add 42.5g of ethylene oxide in batches, keep the reaction temperature below 30°C and stir the reaction for 4h, and then Add 89g of sodium chloroethylsulfonate to the container, raise the temperature to 80°C and continue to stir for 8 hours, pour the product into 500ml of ether to precipitate the crude product, and then recrystallize from a mixed solution of ethanol and ethyl acetate with a volume ratio of 4:1 to obtain The salt-resistant monomer with a purity of 98.5% has a yield of 82.5%.

[0052] In a 1L container equipped with a stirrer, thermometer, condenser and gas inlet and outlet, add 144.2g of acrylamide, 17.3g of acrylic acid, 30.2g of 2-acrylamido-2-methylpropanesulfonic acid, 6.5g of salt-resistant mono Body and 11.2g N-vinylpyrrolidone and 175.5g deionized water, stir to dissolve, then adjust the pH to 6.5 with 30% NaOH solution, then add 14.5g Tween 60 and 5.3g AEO-7...

Embodiment 2

[0054] Put 55g of N-(2-aminoethyl)-acrylamide and 100ml of butanone into a 500mL pressure vessel, add 42.5g of ethylene oxide in batches, keep the reaction temperature below 30°C and stir the reaction for 4h, and then Add 89g of sodium chloroethylsulfonate to the container, raise the temperature to 80°C and continue to stir for 8 hours, pour the product into 500ml of ether to precipitate the crude product, and then recrystallize from a mixed solution of ethanol and ethyl acetate with a volume ratio of 4:1 to obtain The salt-resistant monomer with a purity of 98.5% has a yield of 82.5%.

[0055] Add 142.1g of acrylamide, 16.5g of methacrylic acid, 32.8g of 2-acrylamido-2-methylpropanesulfonic acid, 8.4g of anti- Salt monomer A, 11.0g N-vinylpyrrolidone and 176.2g deionized water were stirred and dissolved, then the pH was adjusted to 6.5 with 30% NaOH solution, and then 14.2g Tween 80 and 5.5g NP-10 were added to dissolve evenly. Under rapid stirring, 205 g of white oil in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com