Nickel-rhenium alloy rotary tubular target containing trace rare earth elements and preparation method thereof

A rare earth element and rhenium alloy technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of low alloy target density, many defects in as-cast structure, low utilization rate, and low quality. Achieve the effects of high gas content, good sputtering effect and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition and content of the nickel-rhenium alloy rotating tubular target in this embodiment are, by mass percentage, respectively: Re 2%, Zr 0.05%, B 0.06%, Mg 0.03%, and the balance of Ni and unavoidable impurities.

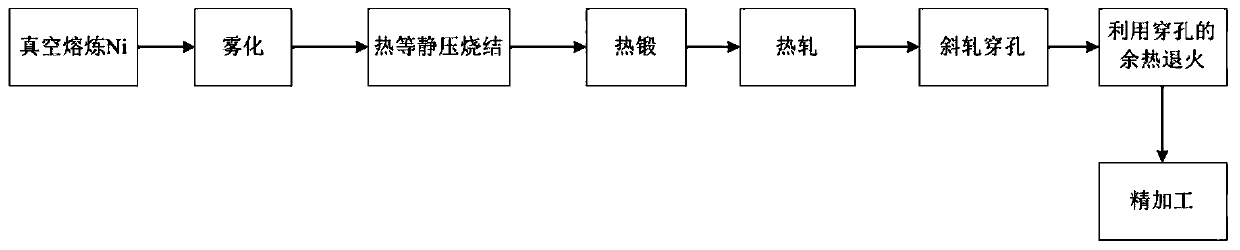

[0036] The preparation process route of the nickel-rhenium alloy rotating tubular target is as follows: figure 1 As shown, it specifically includes the following steps:

[0037](1) Raw material preparation: Prepare raw material electrolytic nickel, rhenium particles, metal chromium, metal zirconium, metal magnesium according to the above-mentioned component content, wherein the purity of raw materials is 99.95% electrolytic nickel, 99.99% rhenium particles, 99.11% metal chromium, 99.36% metal zirconium, 99.9% metal magnesium;

[0038] (2) Vacuum smelting of nickel ingots: use industrial alcohol to remove the dirt on the surface of electrolytic nickel, remove oxides with dilute nitric acid, put the treated electrolytic nickel into a melting crucibl...

Embodiment 2

[0047] The composition and content of the nickel-rhenium alloy rotating tubular target in this embodiment are, by mass percentage, respectively: Re 4%, Zr 0.02%, B 0.05%, Mg 0.01%, and the balance of Ni and unavoidable impurities.

[0048] The preparation method of the nickel-rhenium alloy rotating tubular target in this embodiment is basically the same as that in Embodiment 1, the difference is that:

[0049] In step (2), the melting temperature is 1700° C., and the melting time is 70 minutes;

[0050] In step (3), the vacuum degree of atomization is 10 -3 Pa, the atomization temperature is 1700°C, and the atomization pressure is 8MPa;

[0051] In step (4), the hot isostatic pressing process parameters are 900°C, 135MPa, 3.5h; the sintering temperature is 1300°C, and the sintering pressure is 400bar;

[0052] In step (5), the initial ingot is hot forged, the forging temperature is 1300°C, and the terminal temperature is 1000°C;

[0053] In step (6), the piercing temperatur...

Embodiment 3

[0057] The composition and content of the nickel-rhenium alloy rotating tubular target in this embodiment are, by mass percentage, respectively: Re 5%, Zr 0.03%, B 0.1%, Mg 0.04%, and the balance of Ni and unavoidable impurities.

[0058] The preparation method of the nickel-rhenium alloy rotating tubular target in this embodiment is basically the same as that in Embodiment 1, the difference is that:

[0059] In step (2), the smelting temperature is 1600°C, and the smelting time is 90min;

[0060] In step (3), the atomization vacuum is 1Pa, the atomization temperature is 1500°C, and the atomization pressure is 7MPa;

[0061] In step (4), the hot isostatic pressing process parameters are 950°C, 130MPa, 2h; the sintering temperature is 1100°C, and the sintering pressure is 450bar;

[0062] In step (5), the initial ingot is subjected to hot forging and hot rolling forming, the forging temperature is 1230°C, the terminal temperature is 980°C; the rolling temperature is 1130°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com