A treatment process for the degradation of antibiotic wastewater by an electrochemical membrane filtration coupling system

A technology of antibiotic wastewater and coupling system, which is applied in the treatment process field of electrochemical membrane filtration coupling system to degrade antibiotic wastewater, can solve the problems of membrane pollution, complex method, and long time consumption, and achieve high treatment efficiency, simple preparation method, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

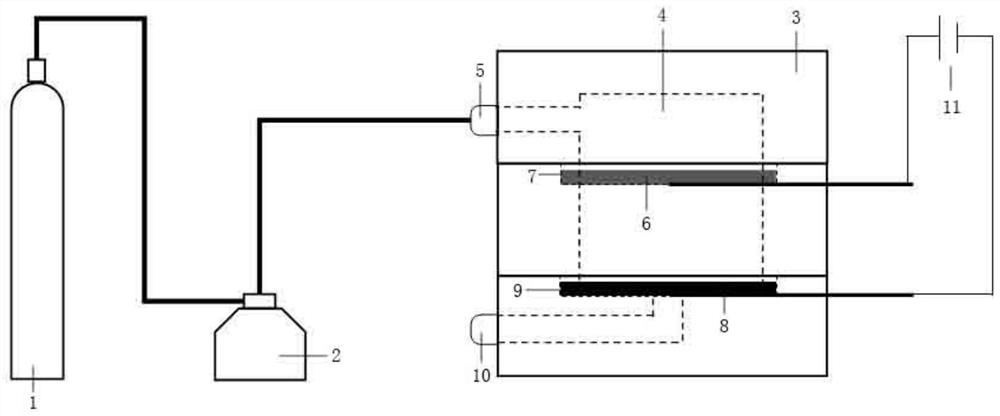

[0031]A treatment process for degrading antibiotic wastewater by an electrochemical membrane filtration coupling system. The treatment process uses an electrochemical membrane filtration coupling system to treat antibiotic wastewater. The electrochemical membrane filtration coupling system includes sequentially connected nitrogen cylinders 1, Liquid control equipment 2 and reactor 3 (reactor 3 is a closed cuboid made of polytetrafluoroethylene material, 8cm long, 8cm wide, and 12cm high. Reactor 3 is assembled from upper, middle and lower parts, two by two By threaded connection); reactor 3 comprises reaction chamber 4 (reaction chamber 4 is cuboid, and cross section is the square of 3 * 3cm, and volume is 0.05L), and the upper end of reactor 3 is provided with water inlet 5 and reaction chamber 4 and respectively. The hydraulic control equipment 2 is connected; the bottom of the water inlet 5 and the side walls around the reaction chamber 4 are horizontally provided with a gro...

Embodiment 2

[0041] A treatment process for degrading antibiotic wastewater by an electrochemical membrane filtration coupling system, as described in Example 1, the difference is: in the treatment process steps, the voltage of the control DC power supply is 3V. Samples were taken at 10 water outlets to determine the antibiotic content.

[0042] After determination, the antibiotic removal rate of the present embodiment method is 82%; after running 8 cycles repeatedly under the same conditions (after processing the antibiotic waste water for half an hour, clean the conductive film with deionized water, and then carry out the treatment of the next batch of waste water, so cycle 8 times), the antibiotic removal rate has only decreased by 0.6%, indicating that the method of the present invention has effectively realized the electrochemical degradation of pollutant antibiotics, and the electrochemical degradation performance is stable, stable operation is possible, and the effluent water quality...

Embodiment 3

[0044] A treatment process for degrading antibiotic wastewater by an electrochemical membrane filtration coupling system, as described in Example 1, the difference is: in the treatment process steps, the concentration of antibiotic wastewater is 10 mg / L, and pH=6.5. Samples were taken at 10 water outlets to determine the antibiotic content.

[0045] After determination, the antibiotic removal rate of the present embodiment method is 70%; after running 8 cycles repeatedly under the same conditions (after processing the antibiotic waste water for half an hour, clean the conductive film with deionized water, and then carry out the treatment of the next batch of waste water, so cycle 8 times), the antibiotic removal rate has only decreased by 0.9%, indicating that the method of the present invention has effectively realized the electrochemical degradation of pollutant antibiotics, and the electrochemical degradation performance is stable, stable operation is possible, and the efflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com