Surface-modified biochar adsorption material and preparation method and application thereof

An adsorption material and surface modification technology, which is applied in the direction of radioactive pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high price and complicated operation steps, and improve the pore structure and specific surface area, enhance the The effect of adsorption and removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

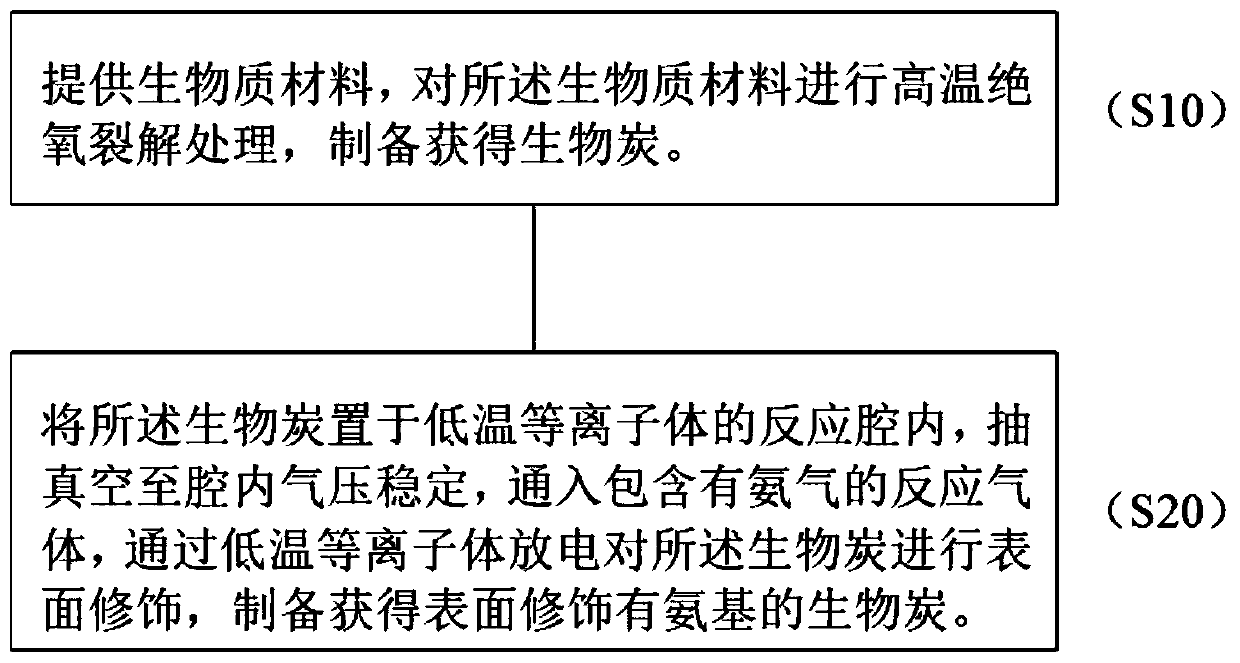

[0029] refer to figure 1 , the preparation method of the above-mentioned surface-modified biochar adsorption material comprises steps:

[0030] S10, providing biomass material, performing high-temperature anaerobic pyrolysis treatment on the biomass material to prepare biochar.

[0031] S20. Place the biochar in the reaction chamber of low-temperature plasma, evacuate until the pressure in the chamber is stable, introduce a reaction gas containing ammonia, and modify the surface of the biochar by low-temperature plasma discharge to prepare A biochar with amino groups modified on the surface was obtained.

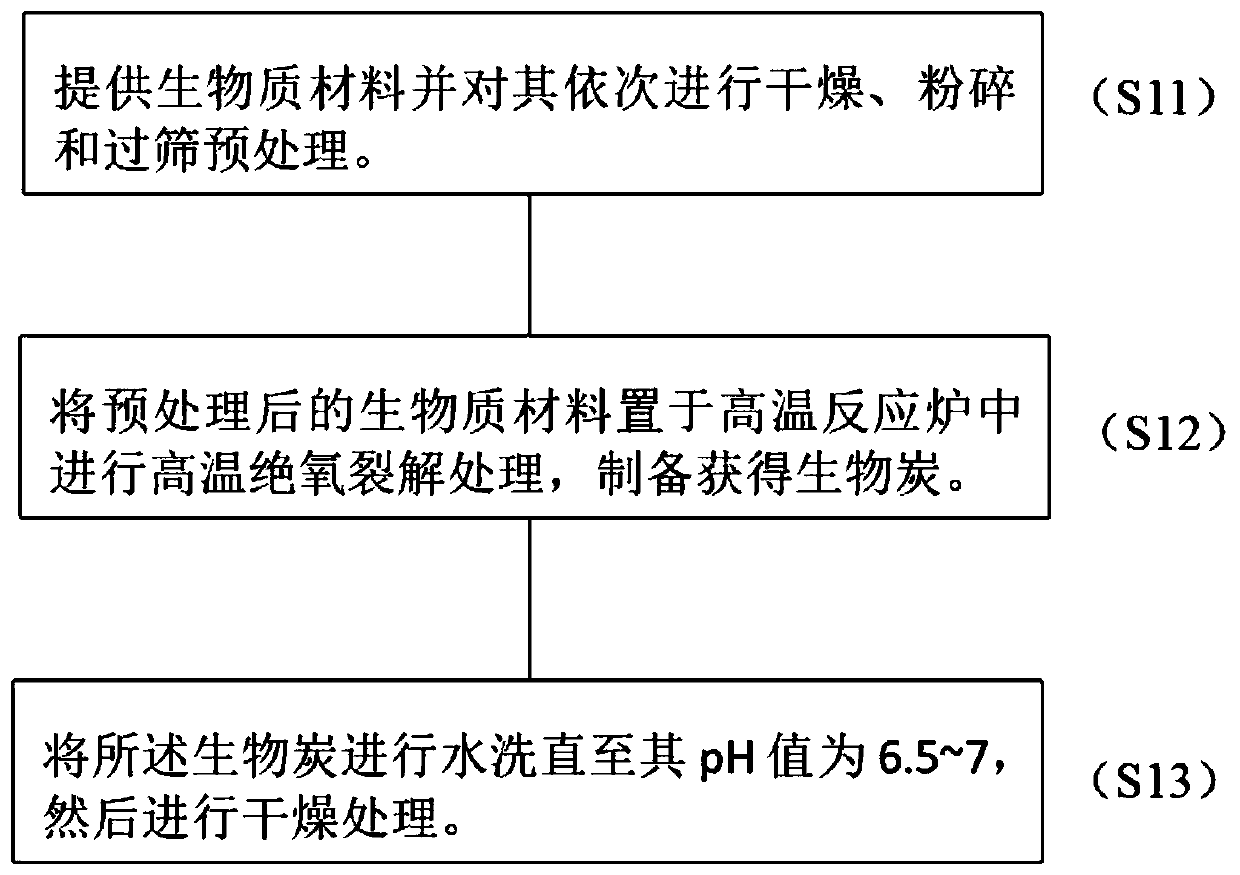

[0032] like figure 2 As shown, the step S10 may specifically include:

[0033] S11, providing biomass material and performing pretreatment on drying, pulverizing and sieving in sequence.

[0034] In a preferred scheme, the biomass material is dried at a temperature of 60° C. to 80° C. for 24 hours to 48 hours to remove excess water in the biomass material, and then crus...

Embodiment 1

[0070] (1) Preparing bamboo powder biochar material: drying, pulverizing and sieving the waste bamboo and wood in sequence. The pretreated material was placed in a tube furnace, cracked at a temperature of 600°C for 2 hours in a nitrogen atmosphere, the heating rate was 10°C / min, and cooled to room temperature under the protection of nitrogen to obtain a bamboo charcoal biochar material. Then the bamboo charcoal biochar was fully rinsed with distilled water, then dried at 60°C for 24 hours, and then dried for use.

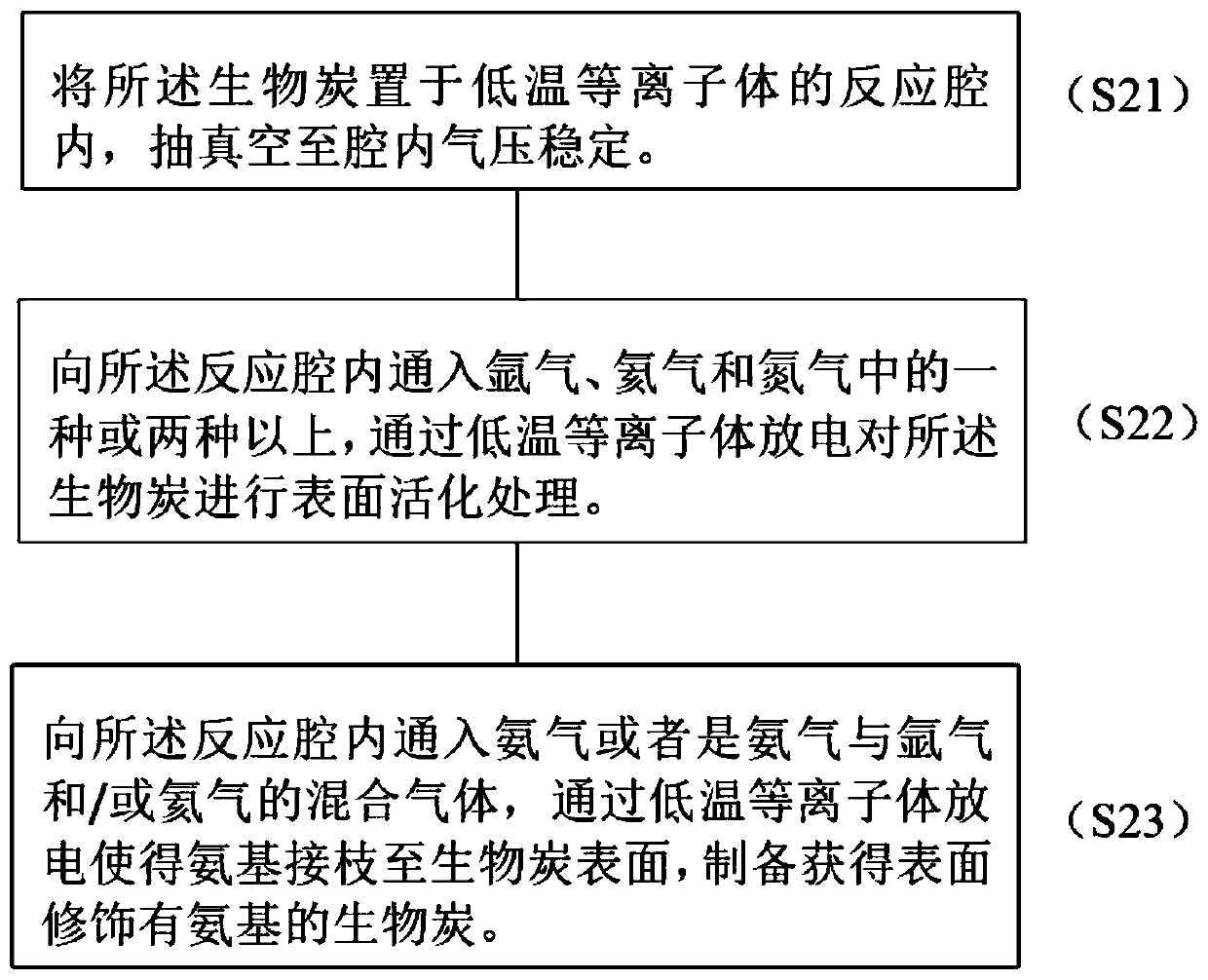

[0071] (2) Plasma amination modification of the surface of biochar:

[0072] Place the bamboo charcoal biochar material obtained above in a low-temperature plasma treatment reaction chamber, feed high-purity argon gas, adjust the flow rate to a vacuum degree of 20.0Pa in the reaction chamber, and perform radio frequency low-temperature plasma discharge after 5 minutes of stabilization, to treat the surface of the material Carry out pretreatment, the treatment time...

Embodiment 2

[0086] (1) Preparation of wheat straw biochar material: dry, crush and sieve wheat straw in sequence. The pretreated material was placed in a tube furnace, cracked at a temperature of 500 °C for 3 h in a nitrogen atmosphere, the heating rate was 15 °C / min, and cooled to room temperature under the protection of nitrogen to obtain wheat straw biochar materials. Then, the wheat straw biochar was fully rinsed with distilled water, then dried at 70°C for 15 hours, and then dried for use.

[0087] (2) Plasma amination modification of the surface of biochar:

[0088] Place the above-obtained wheat straw biochar material in a low-temperature plasma treatment reaction chamber, pass high-purity argon gas, adjust the flow rate to a vacuum degree of 50.0 Pa in the reaction chamber, and conduct radio frequency low-temperature plasma discharge after 5 minutes of stabilization. The surface is pre-treated, the treatment time is 10min, and the discharge power is 100W.

[0089] After the pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com