Cross-magnitude multi-scale line width standard and preparation method thereof

A multi-scale, span-scale technology, applied in the direction of instruments, measuring devices, manufacturing tools, etc., can solve the problems of incompatibility with extremely small, poor repeatability, high cost, etc. simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

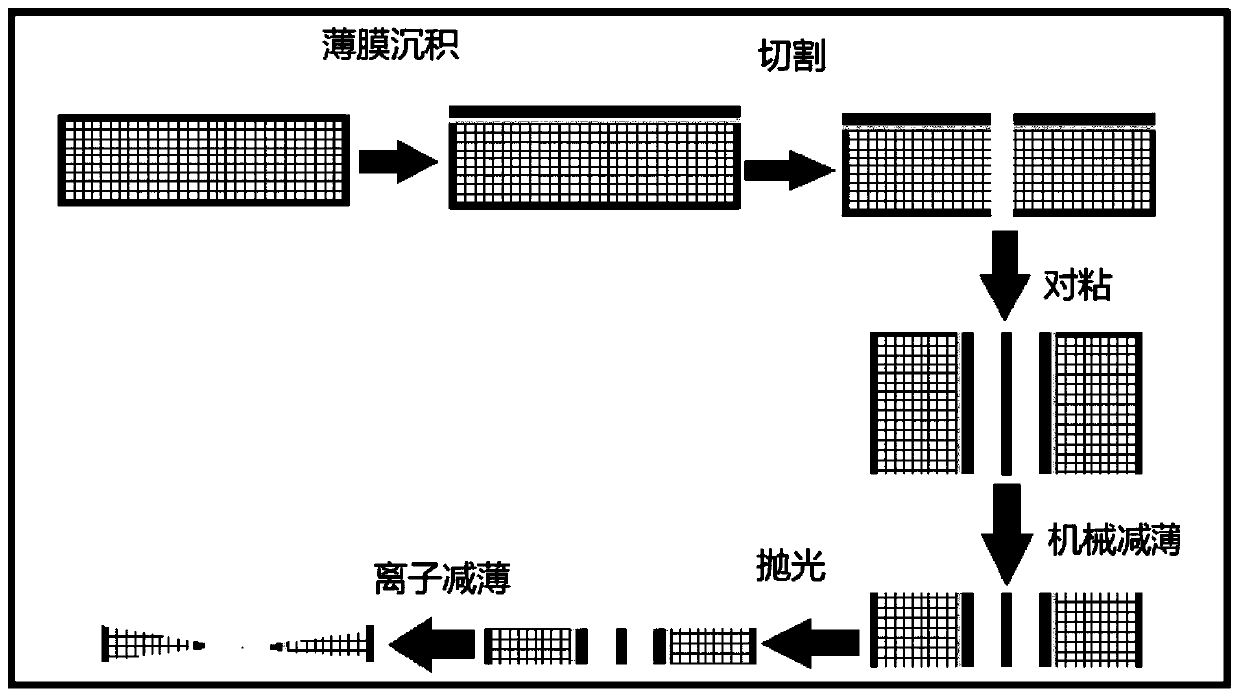

[0031] A method for preparing a span-scale multi-scale linewidth standard provided by the present invention comprises the following steps:

[0032] Step 1, using the atomic layer deposition method to deposit a nano-lamination film formed by two or more materials on the cleaned substrate;

[0033] Among them, the organometallic precursor sources used in the atomic layer deposition method are trimethylaluminum, diethylzinc, tetraethoxysilane, tetrakis(dimethylamino)titanium, tetrakis(methylethylamino)hafnium, tetrakis Any two of (dimethylamino) hafnium, tetrakis (methylethylamino) zirconium and tetrakis (dimethylamino) zirconium.

[0034] The oxygen source used was deionized water (H 2 O), hydrogen peroxide (H 2 o 2 ), oxygen (O 2 ) or ozone (O 3 ).

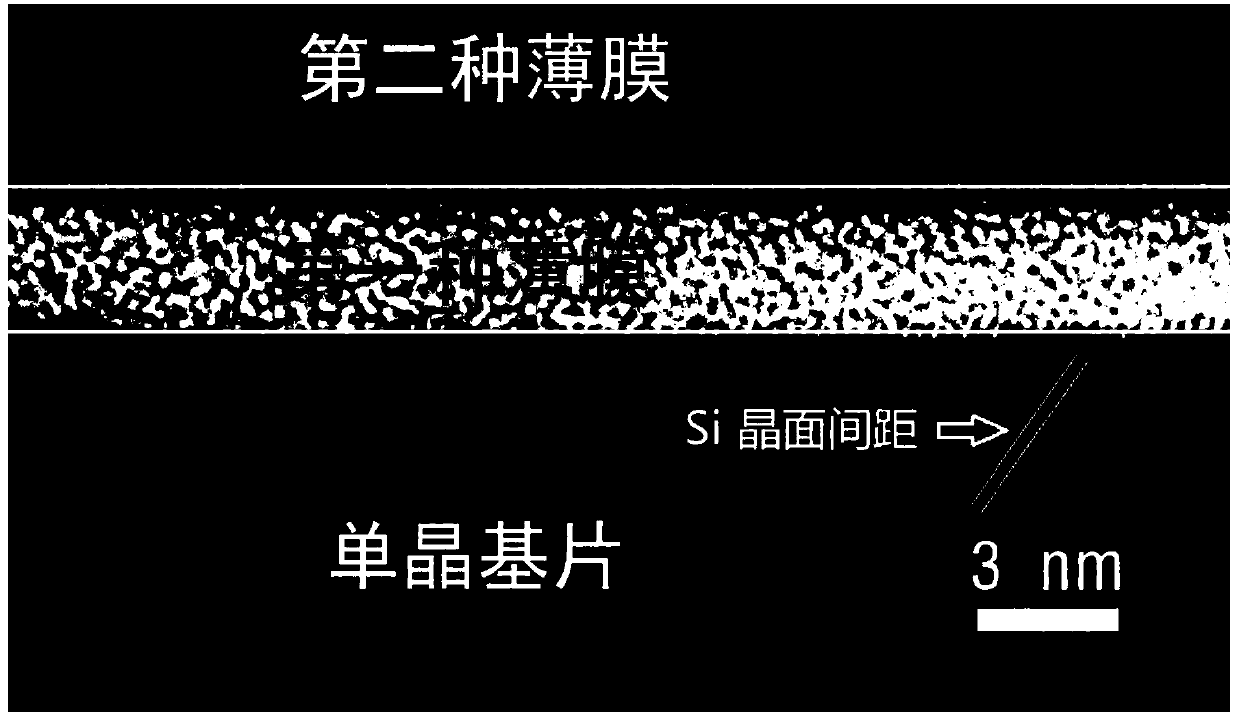

[0035] The deposited first film is SiO 2 film; the deposited second film is a zinc oxide film; the deposited third film is.

[0036] The selected substrate material is an oxide single crystal substrate or a specific orienta...

Embodiment 1

[0047] A method for preparing a span-scale multi-scale linewidth standard provided by the present invention comprises the following steps:

[0048] 1) Cleaning the single crystal Si substrate with RCA standard cleaning process and cleaning its surface with dry nitrogen for subsequent use;

[0049] 2) The single crystal Si substrate processed in step 1 is sent into the atomic layer deposition system through the vacuum loading robot arm of the atomic layer deposition system, and heated to 200°C-300°C to prepare for depositing thin film materials;

[0050] 3) on the basis of step 2, tetraethoxysilane, diethylzinc and deionized water (H 2 O) as precursor sources of Si, Zn and O, respectively, using ALD technology to periodically deposit SiO with a thickness of 3.5 nm on the surface of single crystal Si 2 and 110nm ZnO film; the deposition process parameters are: the first pulse is tetraethoxysilane pulse time is 0.2-0.6, after the pulse is completed, it is purged with 150s ccm ni...

Embodiment 2

[0055] A method for preparing a span-scale multi-scale linewidth standard provided by the present invention comprises the following steps:

[0056] 1) Cleaning the single crystal Si substrate with RCA standard cleaning process and cleaning its surface with dry nitrogen for subsequent use;

[0057] 2) The single crystal Si substrate processed in step 1 is sent into the atomic layer deposition system through the vacuum loading robot arm of the atomic layer deposition system, and heated to 200°C-300°C to prepare for depositing thin film materials;

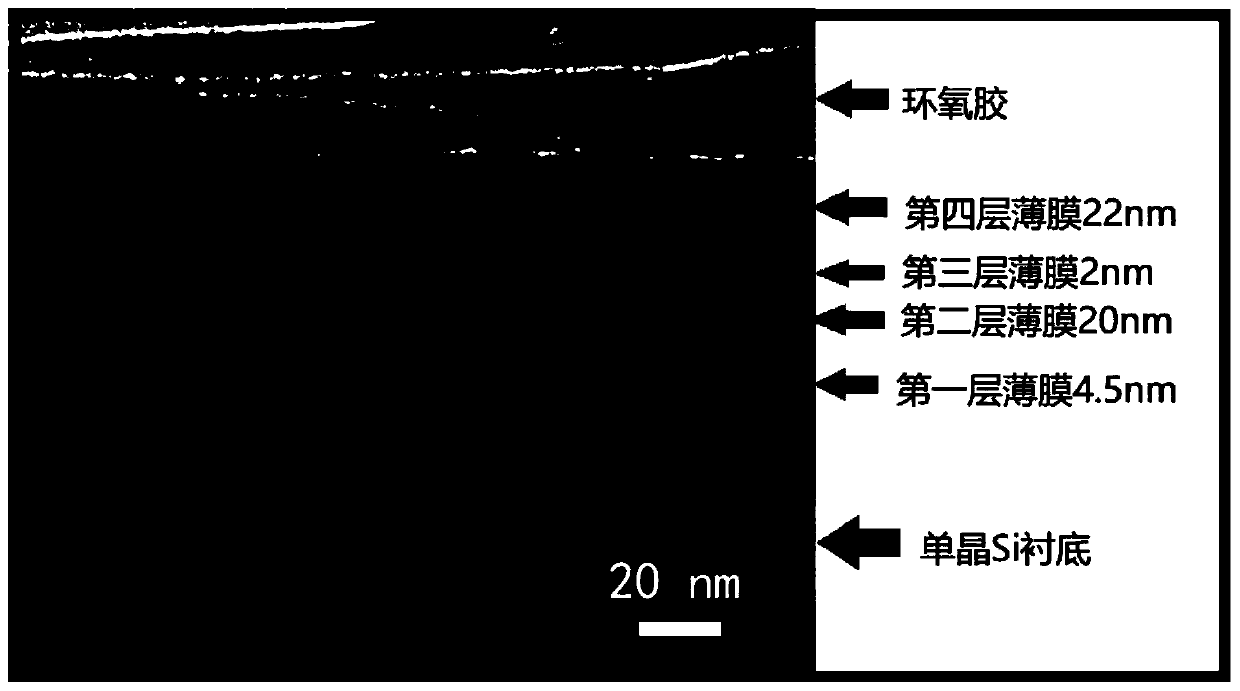

[0058] 3) On the basis of step 2, trimethylaluminum, diethylzinc and deionized water (H 2 O) as precursor sources of Al, Zn and O respectively, using ALD technology to sequentially deposit 4.5nmZnO and 20nmAl on the surface of single crystal Si 2 o 3 , 2nmZnO and 22nm Al 2 o 3 Thin film; the deposition process parameters are: the first pulse is diethyl zinc, and the punching time is 0.1-0.2. After the pulse is completed, it is pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com