Nanometer carbon nitride/copper oxide composite material, and nanometer carbon nitride/copper oxide composite solid-phase micro-extractor, preparation method and applications thereof

A technology of composite materials and carbon nitride, applied in chemical instruments and methods, material separation, analysis of materials, etc., can solve the problem of few reports on sample pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

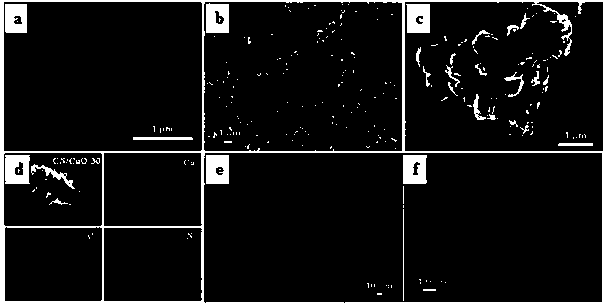

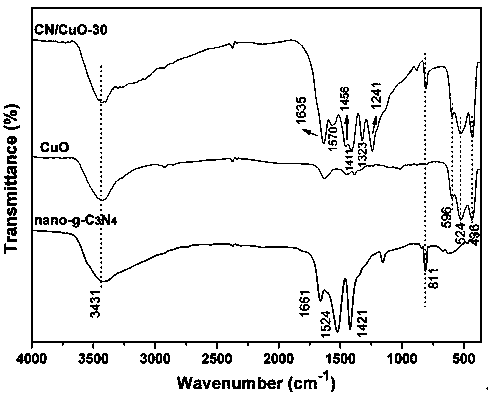

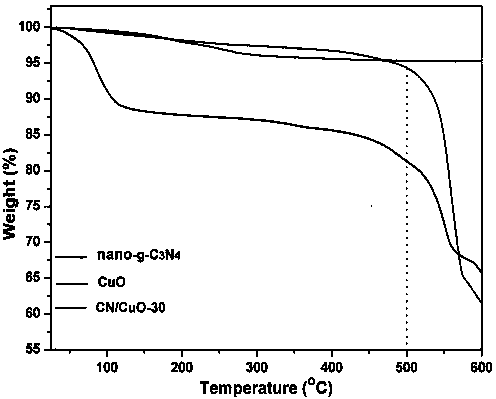

[0039] The preparation process of nanometer carbon nitride / copper oxide composite material is as follows:

[0040] 1) Commercially available carbon nitride is usually bulk carbon nitride (b-g-C 3 N 4 ), which is prepared by thermal polymerization of organic molecules, and there is obvious agglomeration phenomenon, which seriously affects its performance. For this reason, the present invention first ultrasonically disperses the purchased bulk carbon nitride in an 8 M NaOH solution to obtain a suspension, and then stirs the suspension at 70°C for 3 h, during which the suspension becomes It is more viscous. After the reaction, the viscous suspension obtained is centrifuged and the precipitate is collected. The obtained precipitate is washed several times with absolute ethanol until the washing solution is neutral, and the nanometer carbon nitride powder is obtained after drying.

[0041] 2) Weigh 47.4 mg of nano-carbon nitride obtained in step 1) and ultrasonically disperse it ...

Embodiment 2

[0049] The preparation process of the solid-phase microextractor of the nanometer carbon nitride / copper oxide composite material is as follows:

[0050] 1) Thoroughly mix tetraethyl silicate and ethanol evenly, add pH about 2-3 HCl aqueous solution drop by drop under strong stirring with a magnetic stirrer, continue stirring to mix evenly, and obtain clarification after ultrasonic treatment of the reaction mixture Transparent solution, sealed and placed at room temperature, that is, SiO 2 Sol.

[0051] 2) Cut off a quartz fiber with a length of 10-12 cm, and immerse one end of the quartz fiber with a protective layer in acetone for 20-30 min to remove the polyimide on the surface of the fiber to obtain a bare fiber, and dip the bare fiber into Ultrasonic immersion in 1-2 mol / L NaOH solution for 1-2 h to activate the surface of the fiber, ultrasonic vibration with 0.05-0.2 mol / L HCl solution for 30 minutes to neutralize excess NaOH on the fiber, and finally use ultrapure water...

Embodiment 3

[0059] The application of the solid-phase microextractor of nano carbon nitride / copper oxide composite material in the determination of polycyclic aromatic hydrocarbons in water samples comprises the following steps:

[0060] The first step is to determine the content of polycyclic aromatic hydrocarbons in water samples

[0061] The water samples were filtered with a 0.45 μm water-based filter membrane and then directly subjected to subsequent enrichment and adsorption. The solid-phase microextraction process is as follows: Before performing the SPME process, insert the obtained nano-carbon nitride / copper oxide solid-phase microextractor into a 5 μL microinjector, and then place the extraction fiber under the GC condition where the inlet temperature is 280 °C Aging for 1-2 hours to remove impurities on the extraction head; put the water sample and magnets to be tested in the sample bottle, immerse half of the bottle body in the water bath, and push the extraction fiber out of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com