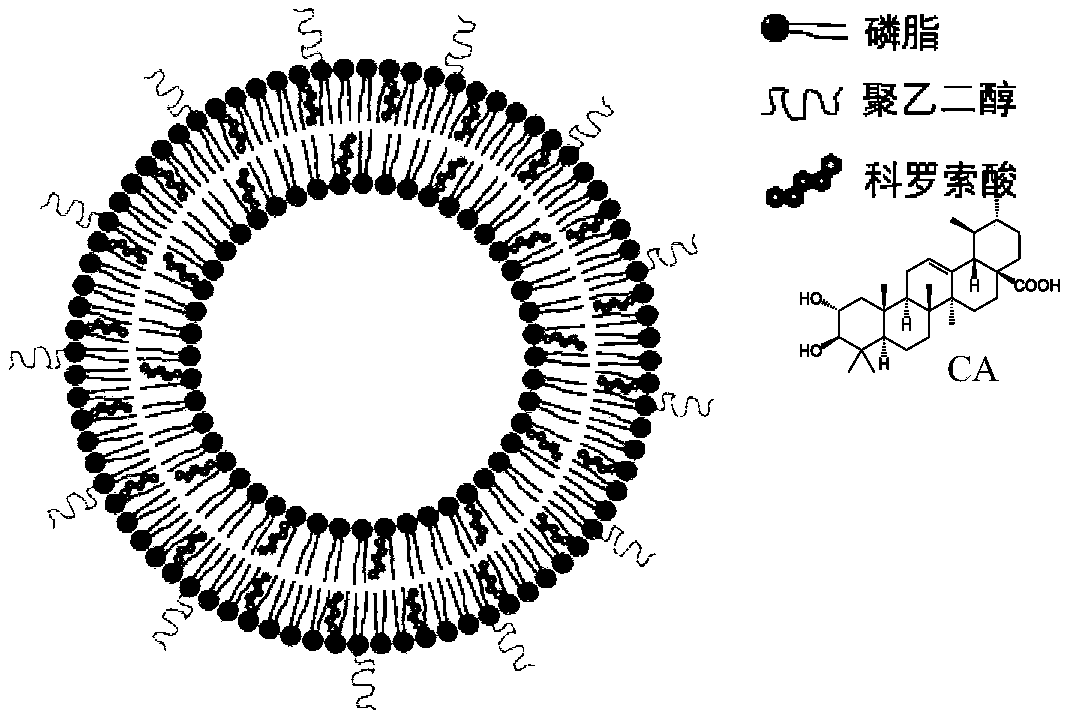

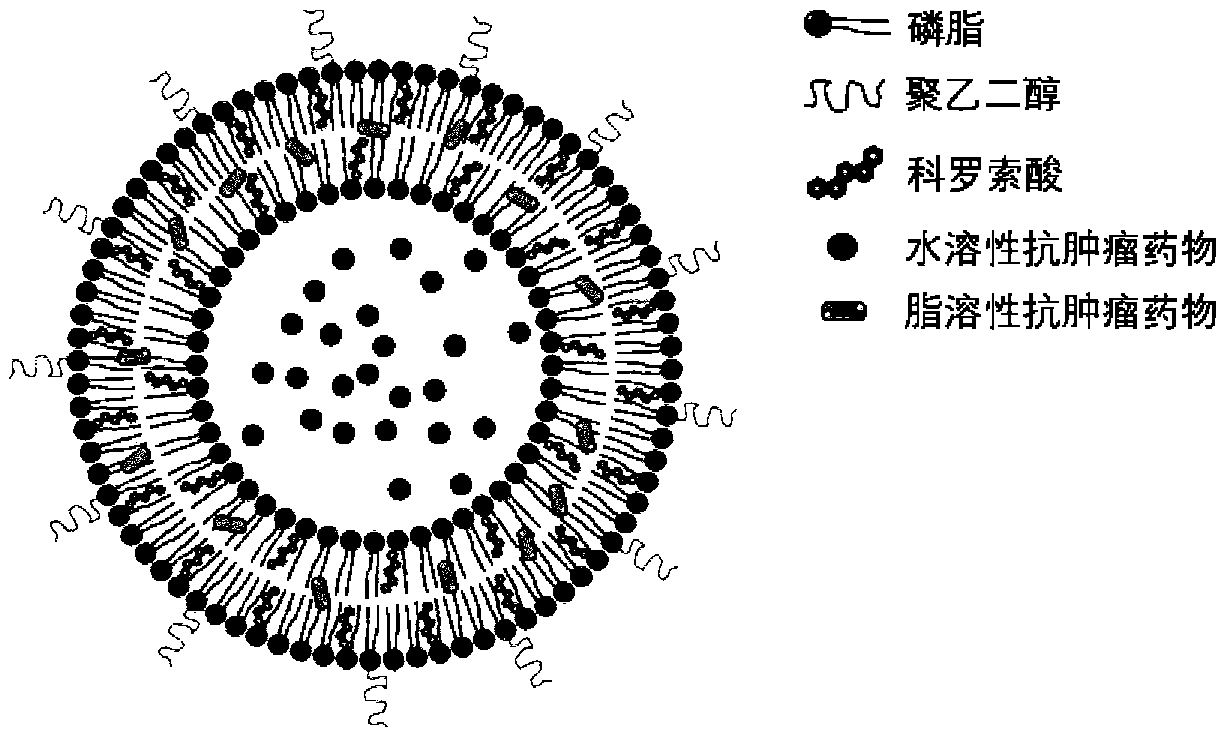

Corosolic acid liposome as well as preparation method and application thereof

A technology of corosolic acid and liposome, which is applied in the field of medical technology and nanomedicine, can solve the problems of poor water solubility of corosolic acid, short circulation half-life, and limited clinical application, and achieve good stability and high drug loading capacity. High, stable and regulating fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

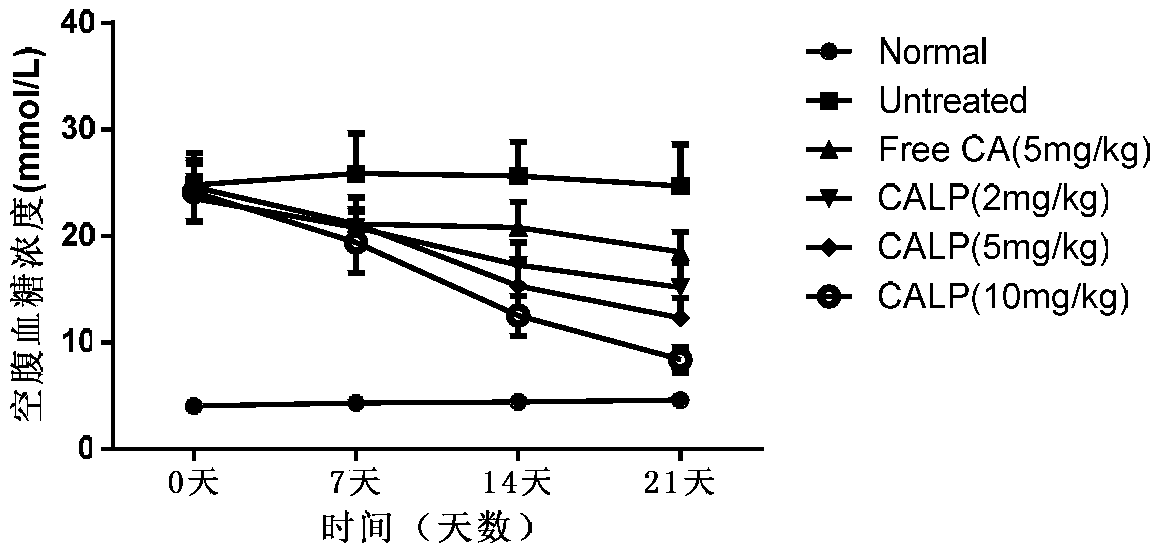

Examples

Embodiment 1

[0045] Embodiment 1 film dispersion method prepares CALP

[0046] Weigh 100mg HSPC, 33.3mg DSPE-MPEG2000, 39mg corosolic acid, dissolve in chloroform / methanol (4 / 1, v / v) to obtain a clear solution; rotary evaporate in a water bath at 40°C, remove the organic solvent, and obtain The membrane was added with physiological saline, hydrated with rotation at 60°C for 2 hours, ultrasonicated at 200W for 20 minutes in an ice-water bath, and eluted through a Sephadex column to obtain a purified CALP liposome suspension. The particle size of the liposome is 90-95nm, and the CA content is 23.2% (w / w).

Embodiment 2

[0047] Embodiment 2 injection method prepares CALP

[0048] Weigh 12mg DSPC, 4mg DSPE-MPEG2000, 4.8mg corosolic acid, dissolve in ethanol, inject the ethanol solution into 60°C physiological saline slowly at a uniform speed, stir continuously at 1000rpm, and ultrasonicate at 200W for 20 minutes in an ice-water bath. Centrifugal purification at 10000rpm to obtain CALP liposome suspension. Its particle diameter and CA content of the CALP prepared by this method are similar to those in Example 1.

Embodiment 3

[0049] Embodiment 3 freeze-thaw method prepares CALP

[0050] Weigh 15mg of DPPC, 4mg of DSPE-MPEG2000, 4.8mg of corosolic acid, dissolve in chloroform / methanol (4 / 1, v / v), rotatively evaporate in a water bath at 40°C, remove the organic solvent to form a film, add physiological saline, Rotating hydration at 40°C for 2 hours to obtain a crude liposome suspension. Place the suspension in a refrigerator at -80°C, take it out after 12 hours and let it melt at room temperature, then place it in a refrigerator at -80°C, and place it at room temperature after 12 hours, repeat this operation 10 times, and then squeeze Press through a 100nm polycarbonate membrane to obtain a CALP liposome suspension. Its particle diameter and CA content of the CALP prepared by this method are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com