Fermentation method for production of gentamicin by continuous feed feeding with oxygen consumption rate as key control parameter

A technology for controlling parameters of gentamicin, which is applied in the fermentation field of continuous fed-batch feeding to produce gentamicin, achieving the effects of good operability, continuous production and resistance maintenance, and continuous increase in titer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

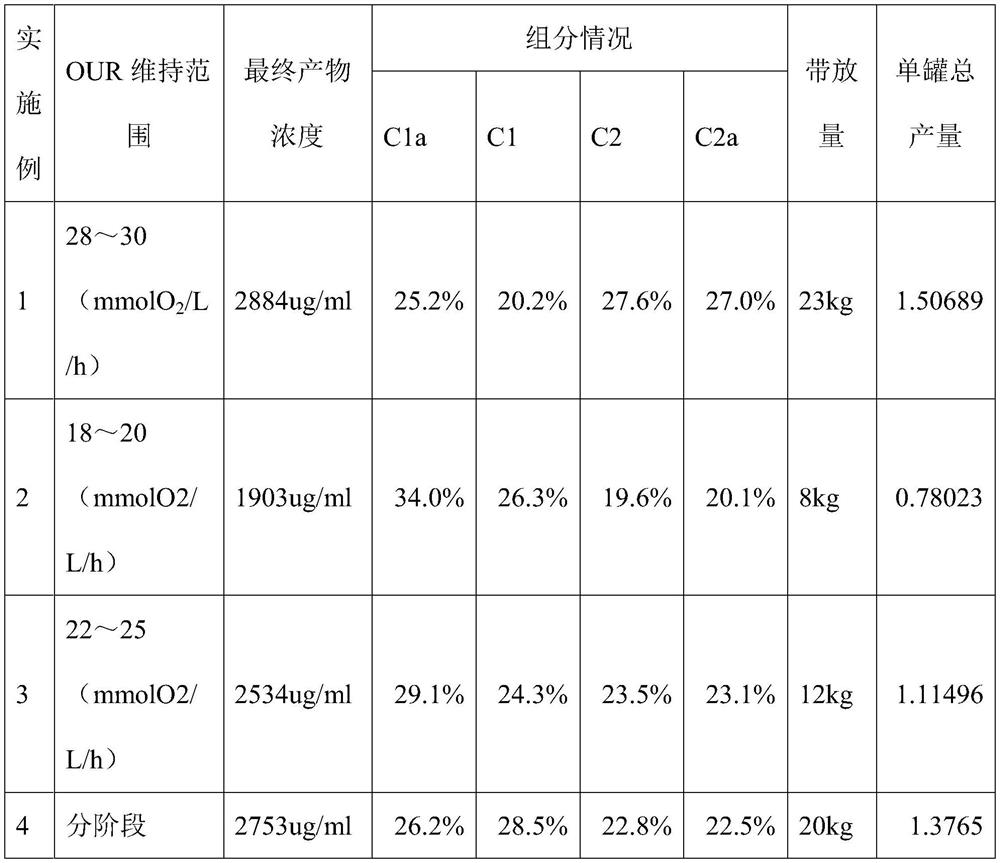

Examples

Embodiment 1

[0029] The strain used in this example is Micromonas aculeatus, which is a mature commercial fungus.

[0030] The entire fermentation process route is: shake flask seeds → primary seed cultivation → secondary seed cultivation → fermentation cultivation.

[0031] Medium composition:

[0032] Primary seed medium (g / L): glucose 1.4, corn starch 15, corn flour 20, angel peptone 2.6, low-temperature soybean flour 20, ammonium sulfate 2.5, potassium nitrate 0.054, calcium carbonate 6.2, foam enemy 0.03, silicone oil 0.05pH 7.2.

[0033] Secondary seed medium (g / L): corn starch 23, corn flour 30, angel peptone 13, bean cake powder 13, ammonium sulfate 5, magnesium sulfate 7.1, potassium nitrate 0.5, calcium carbonate 7, cobalt oxide 0.002, foam Enemy 0.05 and silicone oil 0.03, pH 7.8

[0034]Fermentation basal medium (g / L): corn starch 50, corn flour 20, medium temperature soybean powder 25, angel peptone 23, ammonium sulfate 5, magnesium sulfate 7.1, potassium nitrate 0.5, calci...

Embodiment 2

[0044] The primary seed culture and the secondary seed cultivation are the same as in Example 1, and the fermentation basal medium used in the primary seed medium, the secondary seed medium, and the fermentation culture process are also the same as in Example 1, but the OUR of continuous feeding control different. Feeding control strategy: According to OUR in the early stage of fermentation, when OUR drops to about 22mmol / kg / h, start to supplement sugar and nitrogen, and maintain OUR in the range of 18-20 during the fermentation process. According to the weighing of the fermenter, the volume is controlled at 30-35kg, and when it reaches about 35kg, 5kg is discharged.

Embodiment 3

[0046] The primary seed culture and the secondary seed cultivation are the same as in Example 1, and the fermentation basal medium used in the primary seed medium, the secondary seed medium, and the fermentation culture process are also the same as in Example 1, but the OUR of continuous feeding control different. Feeding control strategy: According to OUR in the early stage of fermentation, when OUR drops to about 28mmol / kg / h, start to supplement sugar and nitrogen, and maintain OUR in the range of 22-25 during the fermentation process. According to the weighing of the fermenter, the volume is controlled at 30-35kg, and when it reaches about 35kg, 5kg is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com