A rare earth-based aerogel material with radiation shielding effect and thermal insulation performance and its preparation and application

A rare earth-based, aerogel technology, applied in applications, ceramic products, household appliances, etc., can solve the problems of poor flame retardancy and single function, and achieve excellent heat insulation performance, high chemical stability, and low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

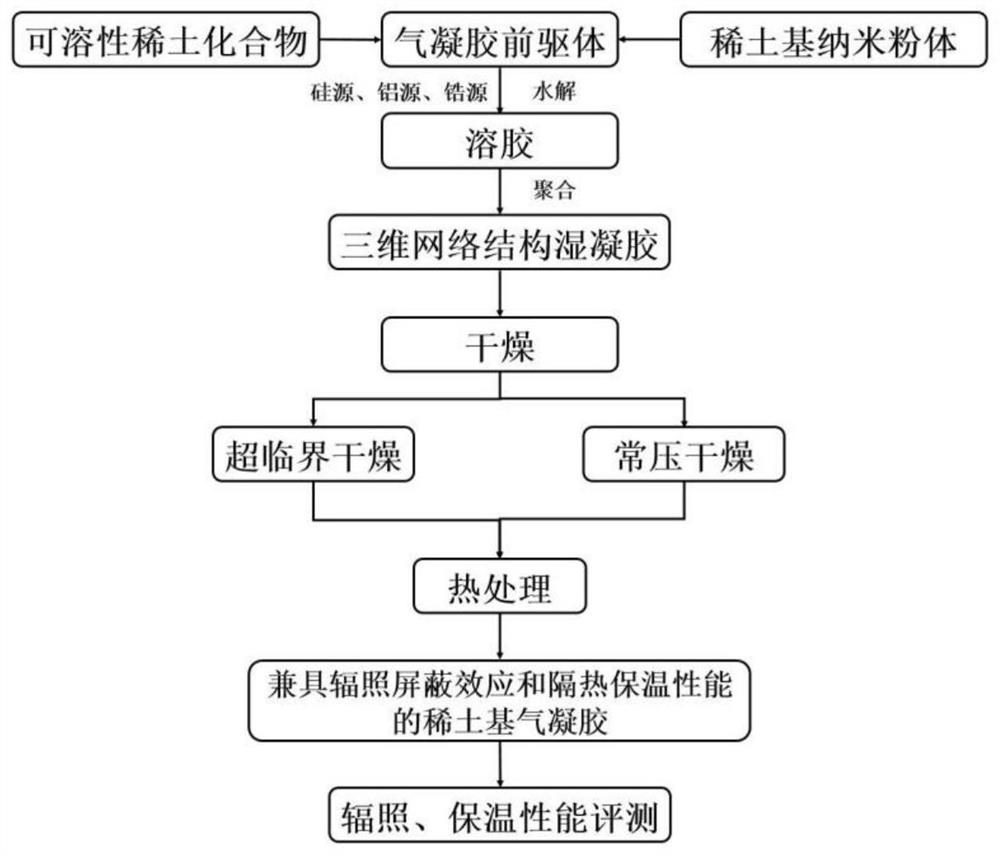

Method used

Image

Examples

Embodiment 1

[0063] This embodiment specifically prepares a composite aerogel material of europium zirconate and silica aerogel matrix material, and the preparation includes the following steps:

[0064] (1) Preparation of precursor mixed solution: Disperse 249 mg of europium nitrate and 240 mg of zirconium nitrate (molar ratio of 1:1) into a mixed solution of 8.4 mL of ethyl orthosilicate, 17.52 mL of ethanol, and 2.54 mL of water (molar ratio is 1:8:3.75);

[0065] (2) adding 200 μL of concentrated hydrochloric acid dropwise to the mixed solution prepared above under continuous stirring until the metal salt is completely dissolved;

[0066] (3) leave standstill for 24 hours to completely hydrolyze ethyl orthosilicate;

[0067] (4) under continuous stirring, the above solution was added dropwise with 0.5M aqueous ammonia solution, adjusted to pH=5.8;

[0068] (5) Transfer the above-mentioned sol to a glass petri dish, and let it stand at room temperature until it loses fluidity, indicat...

Embodiment 2

[0077] This embodiment specifically prepares a composite aerogel material of europium zirconate and alumina aerogel matrix material, and the preparation includes the following steps:

[0078] (1) Preparation of precursor mixed solution: Mix 249 mg of europium nitrate, 240 mg of zirconium nitrate and 9.538 g of aluminum chloride hexahydrate with 23 mL of ethanol and 7.1 mL of water;

[0079] (2) adding 200 μL of concentrated hydrochloric acid dropwise to the mixed solution prepared above under continuous stirring until the metal salt is completely dissolved;

[0080] (3) Add network inducer propylene oxide (n (环氧丙烷) : n (Al) =9mol:1mol);

[0081] (4) Transfer the above-mentioned mixed solution to a glass petri dish and let stand until it is completely gelled;

[0082] (5) immerse the above-mentioned gel in ethanol, and let stand for 48 hours in a constant temperature water bath at 60°C for aging;

[0083] (6) the gel after the above-mentioned aging is immersed in n-hexane, ...

Embodiment 3

[0088] This embodiment specifically prepares a composite aerogel material of europium zirconate and zirconia aerogel matrix material, and the preparation includes the following steps:

[0089](1) Preparation of precursor mixed solution: 762 mg of europium nitrate and 11.56 g of zirconium oxynitrate were added to a mixed solution of 20 mL of ethanol / 5 mL of water;

[0090] (2) the above-mentioned mixed solution is continuously stirred until europium nitrate and zirconium oxynitrate are completely dissolved;

[0091] (3) adding 0.5mol of network-inducing agent propylene oxide in the above-mentioned mixed solution, and continuously stirring and mixing uniformly;

[0092] (4) Transfer the above-mentioned mixed solution to a glass petri dish and let stand until it is completely gelled;

[0093] (5) immerse the above-mentioned gel in ethanol, and let stand for 48 hours in a constant temperature water bath at 60°C for aging;

[0094] (6) Transfer the gel after the above-mentioned a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com