Method of preparing solid-state lithium ion battery through photocuring 3D printing

A lithium-ion battery, 3D printing technology, applied in the direction of secondary battery, secondary battery manufacturing, 3D object support structure, etc., can solve the problem of poor cycle stability of time-consuming and energy-consuming batteries, cycle stability of time-consuming and energy-consuming batteries Solve problems such as complicated process, achieve the effect of improving interface compatibility, shortening process cycle, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] Preparation of photosensitive polymer network matrix: mix photosensitive resin, photoinitiator and polymer matrix according to a certain mass ratio to form semi-IPN, the semi-interpenetrating polymer network framework Semi-IPN, and then mix lithium salt solution and semi-interpenetrating polymer framework Semi-IPN -IPN mixed to obtain a photosensitive polymer network matrix with lithium ion conductivity.

[0076] Preparation of inorganic oxide nano-active fillers: As one of the key improvements of the present invention, the product obtained in this step—ceramic nanoparticles with lithium-ion conductive activity plays an important role in the printing and ionic conductivity of composite solid electrolytes. important influence. The corresponding salts can be added to ethylene glycol in sequence, and then citric acid monohydrate is added to stir to obtain a clear solution; the obtained clear solution is heated to reflux, aged, carbonized, and then calcined at a high temper...

Embodiment 1

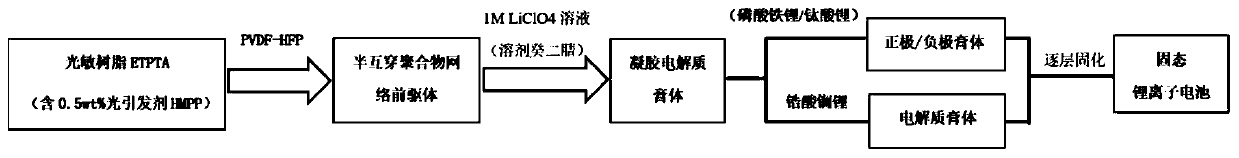

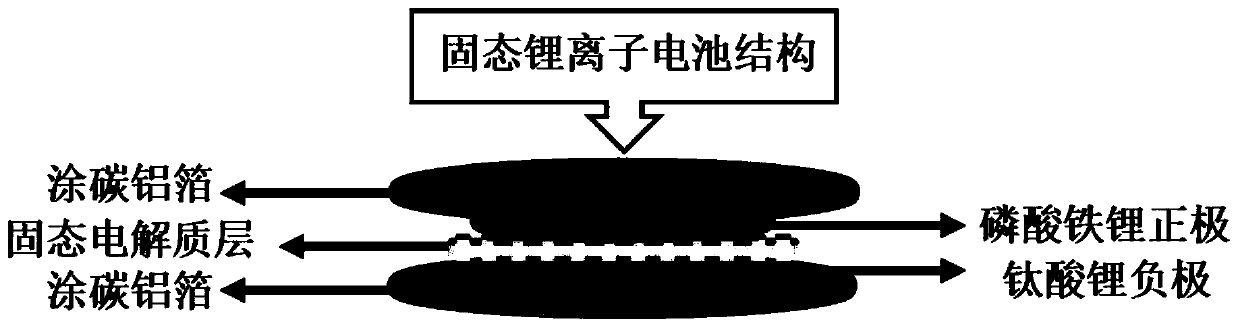

[0085] figure 1 It is a schematic diagram of the process flow for preparing a solid-state lithium-ion battery by 3D printing constructed according to the present invention, figure 2 It is a schematic diagram for exemplarily showing the composition and structure of a solid-state lithium-ion battery prepared according to the present invention. Such as figure 1 As shown in , the process mainly includes the following process steps:

[0086] First, the preparation of the photosensitive polymer network matrix.

[0087] In this step, a photosensitive resin (ethoxylated trimethylolpropane triacrylate (ETPTA, Aldrich) containing 1.0 wt% of photoinitiator (2-hydroxy-2-methyl-1-phenyl- 1-acetone (HMPP) and polyvinylidene fluoride-hexafluoropropylene copolymer (PVdF-HFP, Sigma, HFP content 6mol%), mixed according to a certain mass ratio (ETPTA / PVdF-HFP=75 / 25 (w / w)) , to form a semi-interpenetrating polymer network skeleton IPN, and then lithium salt solution (1M LiClO 4 solution, th...

Embodiment 2

[0108] A photosensitive polymer network matrix used for photocuring 3D printing to prepare solid-state lithium-ion batteries, the photosensitive polymer network matrix includes a semi-interpenetrating polymer network skeleton and a lithium salt solution; the lithium salt solution is dispersed in the semi- In the interpenetrating polymer network skeleton, wherein: the semi-interpenetrating polymer network skeleton includes a photosensitive resin, a photoinitiator and a polymer matrix, the photosensitive resin has a network crosslinked structure, and the photoinitiator is used to initiate The photosensitive resin undergoes a polymerization reaction; the polymer matrix has a linear non-crosslinked structure; the lithium salt solution is an organic solution obtained by dissolving lithium salt in an organic solvent.

[0109] The lithium salt in the lithium salt organic solution is lithium tetrafluoroborate, the organic solvent is sebaconitrile, and the concentration of the lithium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coulomb effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com