Method for preparing copper-nickel alloy nanometer material with cutting-angle twin-cone morphology features in hydrophobic phase

A technology of morphology characteristics and copper-nickel alloy, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as complex steps and easy agglomeration, and achieve easy-to-obtain raw materials and high catalytic performance The effect of reactivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix and stir 1mmol copper acetylacetonate, 1mmol nickel acetylacetonate, 0.1mmol tri-n-octylphosphine oxide and 50mL oleylamine, keep the mixture at 170°C for 1h, cool to room temperature, and wash the reaction solution to obtain a bipyramid with truncated angle. Morphological characterization of copper-nickel alloy nanomaterial products.

[0027] Such as figure 1 , the copper-nickel alloy nanomaterials prepared in this embodiment have the feature of chamfered biconical shape, that is, the upper apex and the lower apex are cut on the basis of triangular bipyramids. The apex angle of each triangular face of the cone is 90 degrees;

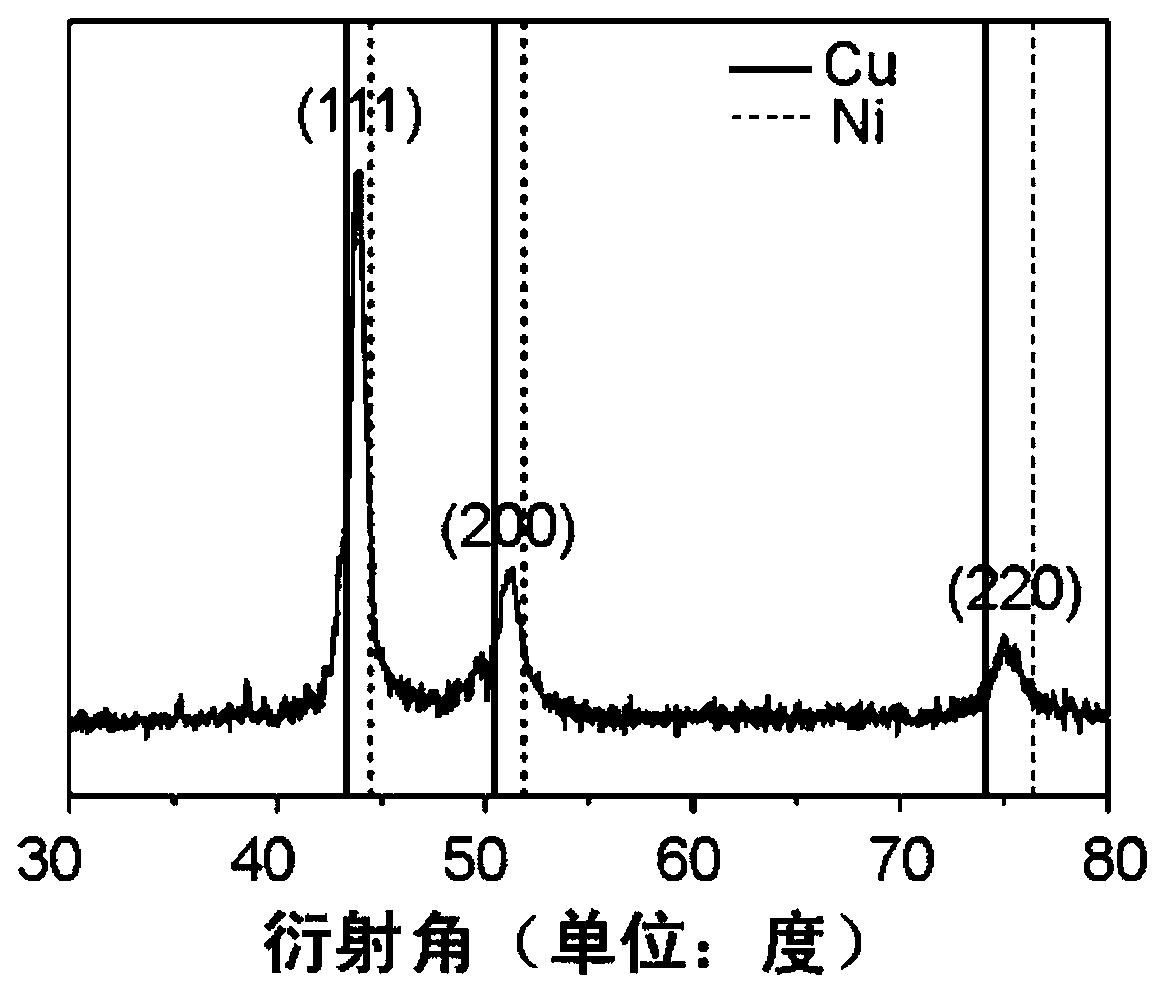

[0028] Such as figure 2 , the characteristic diffraction peaks in the X-ray diffraction pattern of the product obtained in this example are located between the corresponding characteristic diffraction peaks of Cu and Ni, which proves the copper-nickel alloying characteristics of the product

Embodiment 2

[0030] Mix and stir 1mmol copper chloride, 1mmol nickel acetylacetonate, 0.1mmol trioctylphosphine and 30mL oleylamine, keep the mixture at 200°C for 1h, cool to room temperature, and wash the reaction solution to obtain a biconical shape with truncated corners Characterization of copper-nickel alloy nanomaterial products.

Embodiment 3

[0032] Mix and stir 10mmol copper sulfate, 1mmol nickel acetylacetonate, 0.1mmol trioctylphosphine and 40mL oleylamine, keep the mixture at 150°C for 1.5h, cool to room temperature, and wash the reaction solution to obtain a bipyramidal shape with truncated corners. Characterization of copper-nickel alloy nanomaterial products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com