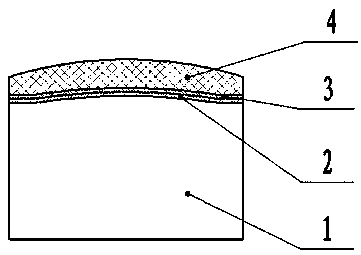

Circular-arch-shaped polycrystalline diamond composite sheet preparing method

A technology of polycrystalline diamond and composite sheet, which is applied in metal material coating technology, ion implantation plating, gaseous chemical plating, etc., can solve the problems of low drilling efficiency, poor impact resistance, interface cracks, etc., and achieve improvement The effect of excessive residual stress, enhanced bonding strength, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a circular arched polycrystalline diamond composite sheet, comprising the following steps:

[0035] Step 1) Substrate purification treatment: the cemented carbide substrate is composed of the following raw materials in weight percentage: 5% cobalt, tantalum niobium solid solution (TaC:NbC=6:4) 3%, tungsten carbide 91% and samarium oxide 1 %, the hardness of the cemented carbide is 93.5HRA, and the bending strength is 2550N / mm; first, the cemented carbide substrate is immersed in deionized water and potassium hydroxide with a mass ratio of 1:0.1 in the lye solution and boiled for 2 minutes, and then the hard alloy The alloy substrate was immersed in a sulfuric acid solution prepared with a mass fraction of 98% sulfuric acid and deionized water at a volume ratio of 1:4 for ultrasonic vibration cleaning for 2 minutes, then immersed in an acetone solution for ultrasonic vibration cleaning for 5 minutes, and then the cemented carbide substrate was plac...

Embodiment 2

[0049] A preparation method of a circular arched polycrystalline diamond composite sheet, comprising the following steps:

[0050] Step 1) Purification treatment of cemented carbide substrate: The cemented carbide substrate is composed of the following raw materials in weight percentage: 8% cobalt, 2% tantalum-niobium solid solution (TaC:NbC=6:4), 89.5% tungsten carbide and Samarium oxide 0.5%, the hardness of the cemented carbide is 94HRA, and the bending strength is 2530N / mm; first, the cemented carbide substrate is immersed in deionized water and potassium hydroxide in a lye prepared with a mass ratio of 1:0.2 and boiled for 5 minutes, and then The cemented carbide substrate was immersed in a sulfuric acid solution prepared with a mass fraction of 98% sulfuric acid and deionized water at a volume ratio of 1:5 for ultrasonic vibration cleaning for 5 min, and then immersed in absolute ethanol for 10 min for ultrasonic vibration cleaning. Then place the cemented carbide substr...

Embodiment 3

[0065] A preparation method of a circular arched polycrystalline diamond composite sheet, comprising the following steps:

[0066] Step 1) Purification treatment of cemented carbide substrate: The cemented carbide substrate is composed of the following raw materials in weight percentage: 6.5% cobalt, 2.5% tantalum niobium solid solution (TaC:NbC=6:4), 90.25% tungsten carbide and Samarium oxide 0.75%, the hardness of the cemented carbide is greater than 93.8HRA, and the bending strength is 2510N / mm; first, the cemented carbide substrate is immersed in the lye prepared by deionized water and potassium hydroxide at a mass ratio of 1:0.15 and boiled for 2.5min , and then immerse the cemented carbide substrate in a sulfuric acid solution prepared with a mass fraction of 98% sulfuric acid and deionized water at a volume ratio of 1:4.5 for ultrasonic vibration cleaning for 2.5 min, and then immersed in acetone for 7.5 min for ultrasonic vibration cleaning. Then place the cemented car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com