Self-supporting binary metal sulfide composite material and preparation method thereof, lithium ion battery negative electrode and lithium ion battery

A lithium-ion battery and binary metal technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of limiting the capacity of lithium-ion batteries, powdering of negative electrode materials, poor conductivity, etc., and improve electrochemical performance , good growth and compactness, and the effect of enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a self-supporting binary metal sulfide composite material, comprising the following steps:

[0045] A, solution reaction procedure: 0.1725g zinc sulfate heptahydrate, 0.1577g nickel sulfate hexahydrate, 0.5821g cobalt nitrate hexahydrate are dissolved in 40ml deionized water, stir 30min, obtain the solution containing zinc salt, nickel salt and cobalt salt, 1 g of 2-methylimidazole was dissolved in 40 ml of deionized water, and stirred for 30 minutes to obtain a 2-methylimidazole solution, and the two solutions were mixed and stirred at room temperature for 5 minutes to obtain a mixed solution.

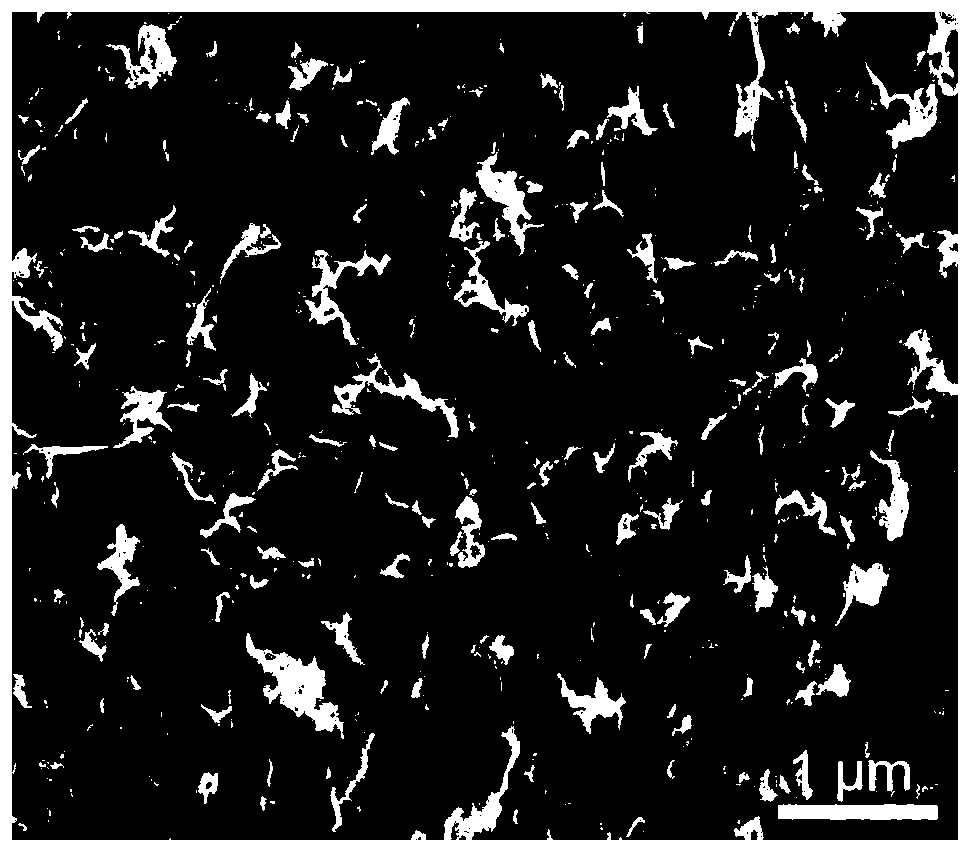

[0046] B. Composite process: Cleaning of carbon cloth: Cut the carbon cloth into small pieces of 1cm×1cm, put them into a 50ml beaker, and ultrasonically clean them with acetone, ethanol and deionized water for 15 minutes respectively. Put the cleaned carbon cloth into the mixed solution in step A, let it stand at room temperature for 4h, then take out th...

Embodiment 2

[0049] A method for preparing a self-supporting binary metal sulfide composite material, comprising the following steps:

[0050] A, solution reaction procedure: 0.1785g zinc nitrate hexahydrate, 0.1745g nickel nitrate hexahydrate, 0.6748g cobalt sulfate heptahydrate are dissolved in 40ml deionized water, stir 30min, obtain the solution containing zinc salt, nickel salt and cobalt salt, Dissolve 1.2 g of 2-methylimidazole in 40 ml of deionized water and stir for 30 minutes to obtain a 2-methylimidazole solution. Mix and stir the two solutions at room temperature for 5 minutes to obtain a mixed solution.

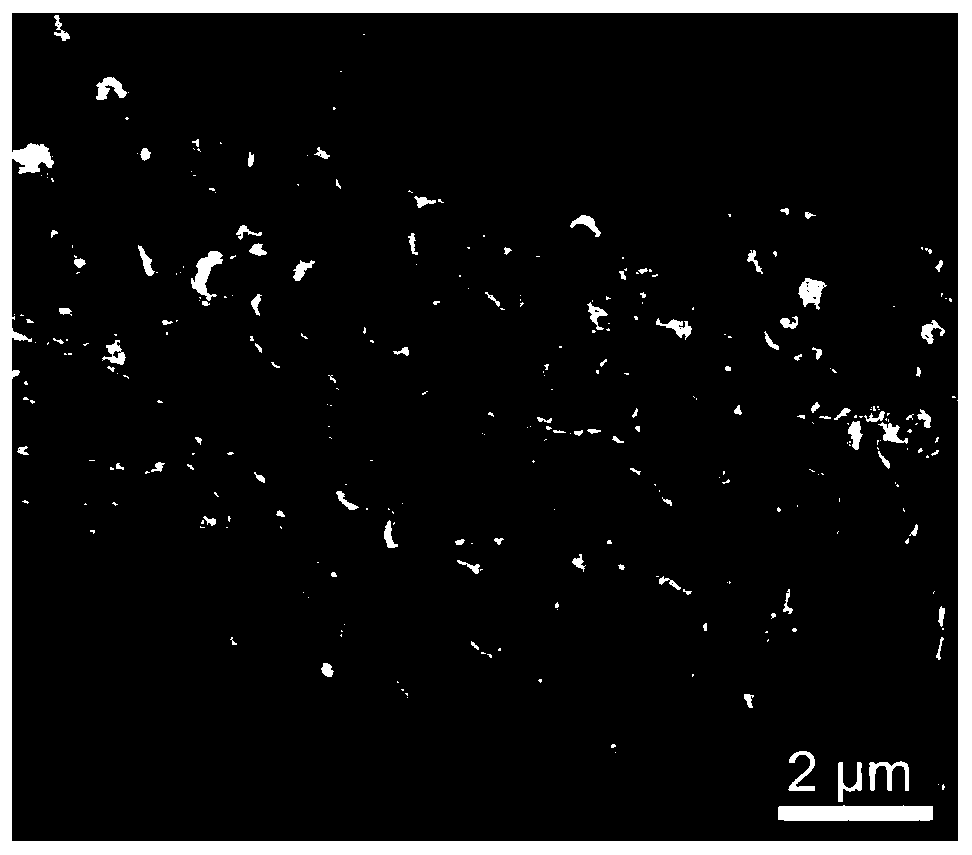

[0051] B. Composite process: the cleaning of the carbon cloth is the same as in Example 1. Put the cleaned carbon cloth into the mixed solution in step A, let it stand at room temperature for 8h, then take out the carbon cloth with material, rinse it with deionized water three times, and dry it at 60°C for 12h to obtain Zn / Ni / Co-ZIF / carbon cloth composite.

[0052] C, hydr...

Embodiment 3

[0054] A method for preparing a self-supporting binary metal sulfide composite material, comprising the following steps:

[0055] A, solution reaction process: 0.2876g zinc sulfate heptahydrate, 0.2629g nickel sulfate hexahydrate, 1.1641g cobalt nitrate hexahydrate were dissolved in 40ml deionized water, stirred for 30min, to obtain a solution containing zinc salt, nickel salt and cobalt salt, Dissolve 1.4 g of 2-methylimidazole in 40 ml of deionized water and stir for 30 minutes to obtain a 2-methylimidazole solution. Mix and stir the two solutions at room temperature for 5 minutes to obtain a mixed solution.

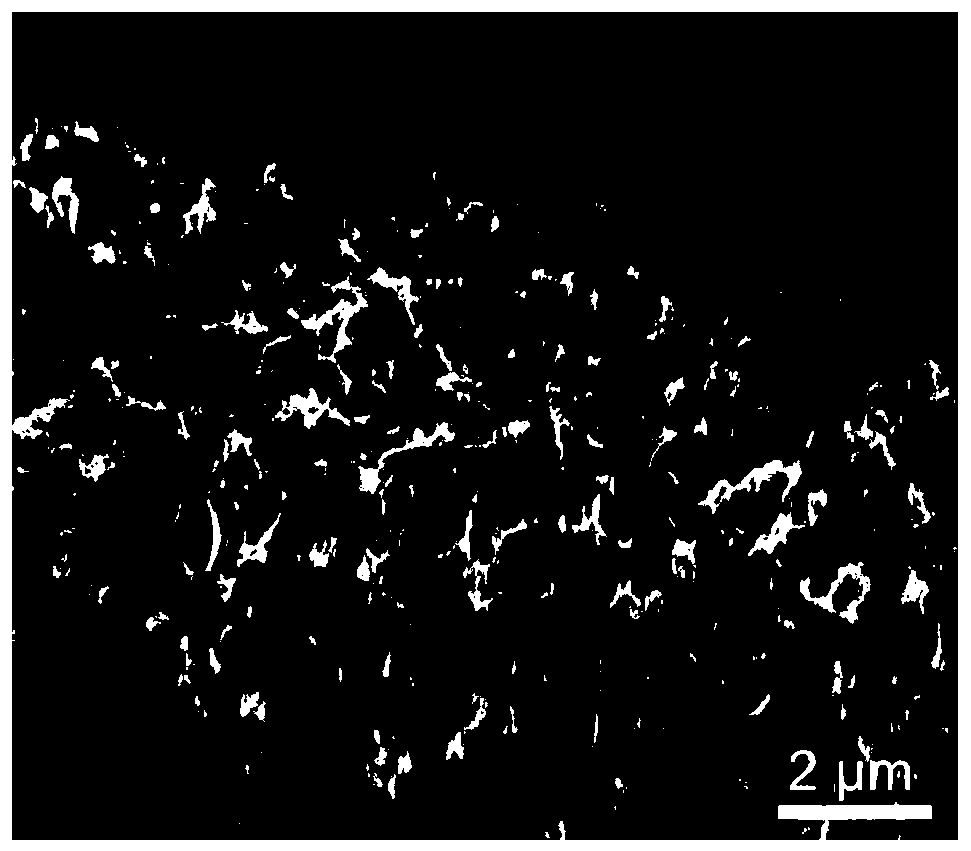

[0056] B. Composite process: the cleaning of the carbon cloth is the same as in Example 1. Put the cleaned carbon cloth into the mixed solution in step A, let it stand at room temperature for 5h, then take out the carbon cloth with material, rinse it with deionized water three times, and dry it at 60°C for 12h to obtain Zn / Ni / Co-ZIF / carbon cloth composite.

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com