Preparation for repairing petroleum hydrocarbon pollutants and application of preparation

A technology of petroleum hydrocarbons and pollutants, applied in the field of soil remediation, to achieve the effects of improving efficiency, saving resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Immobilized Microbial Materials

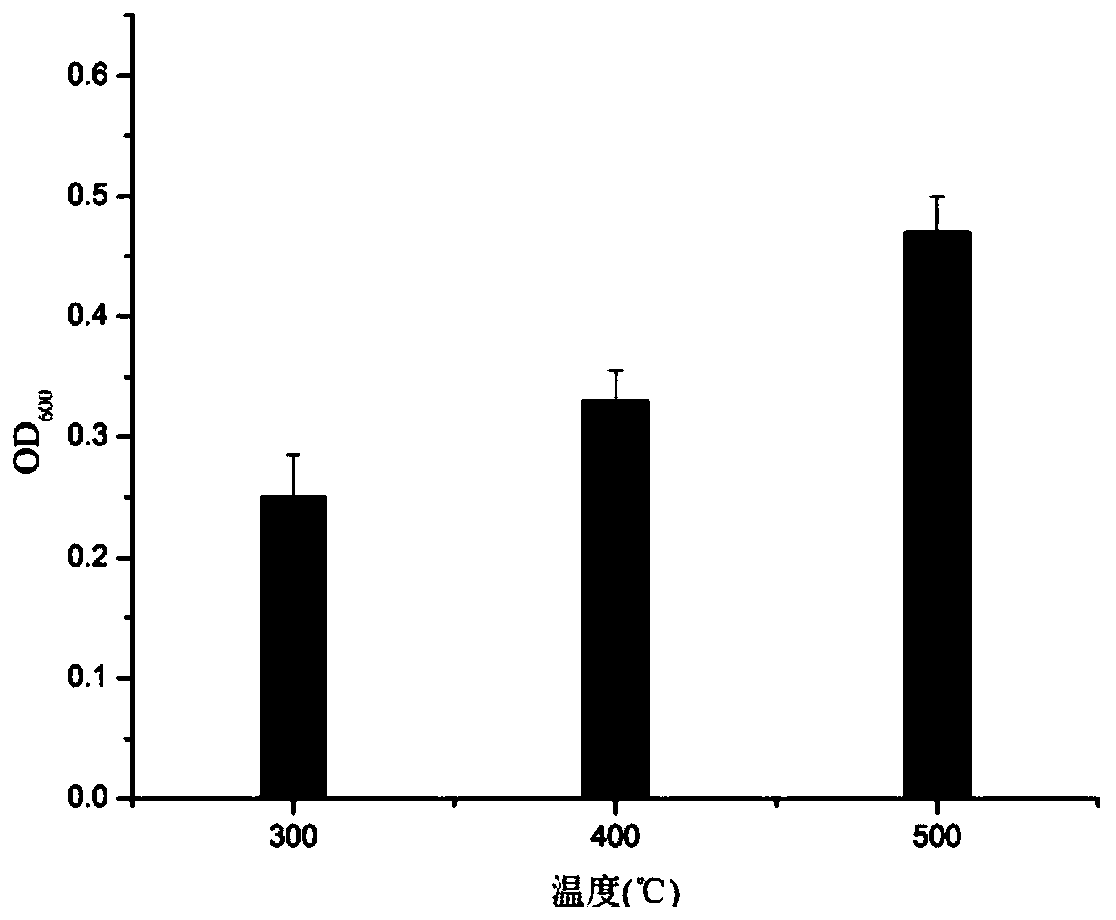

[0036] (1) Biochar is prepared from agricultural waste biomass corn stalks as raw material. Remove impurities from the straw, dry it naturally for 7 days after cleaning, and preliminarily pulverize it to a size of 1-2 cm, dry it at 50 °C for 4 hours, put the straw into a muffle furnace after drying, and pass high-purity nitrogen for 20 minutes before heating to form an oxygen-free environment, the heating rate of 5 °C / min was heated to 300, 400, and 500 °C, respectively, and pyrolyzed at each temperature for 2 hours to obtain biochar materials with different pyrolysis temperatures; Save for backup.

[0037] (2) Resuscitate and culture Acinetobacter HC8-3S and Dijianella CN-3 stored in -80°C refrigerator, respectively, transfer the resuscitated bacteria liquid to 2216E medium, at 30°C, 150rpm Expand the culture in a constant temperature shaker to obtain bacterial suspensions of the two strains of bacteria, and mix the tw...

Embodiment 2

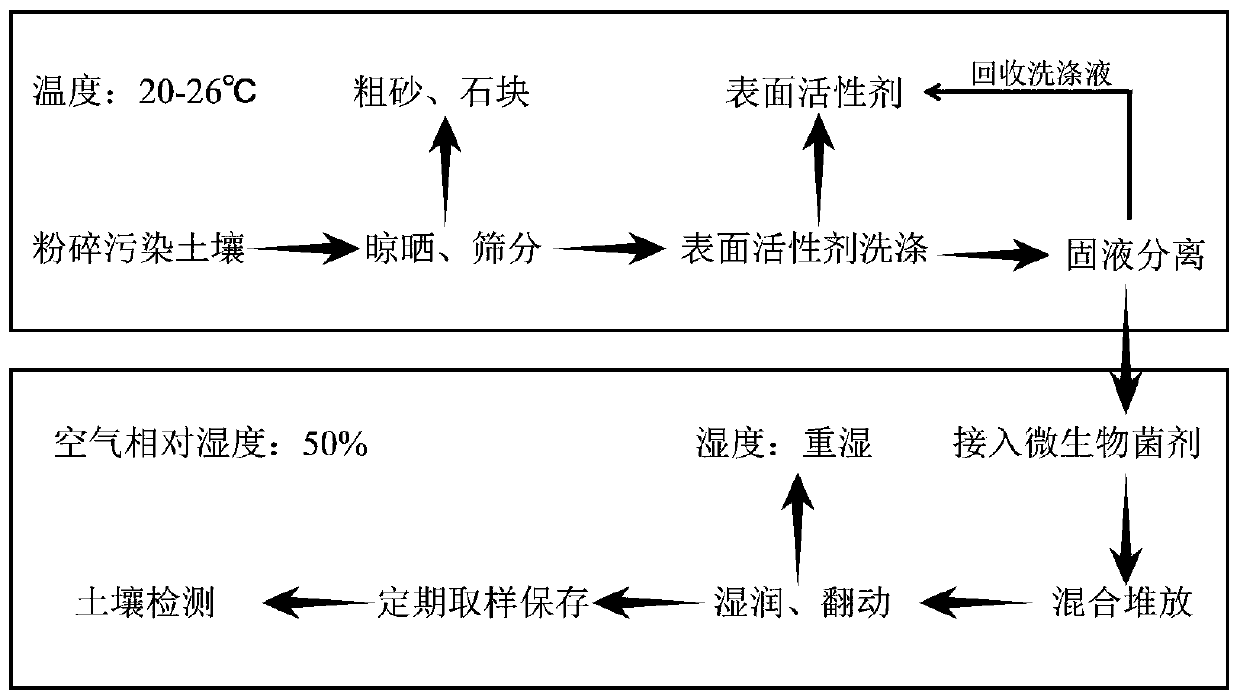

[0043] Remediate contaminated soil, such as figure 1 shown:

[0044] 1) Surfactant to clean contaminated soil

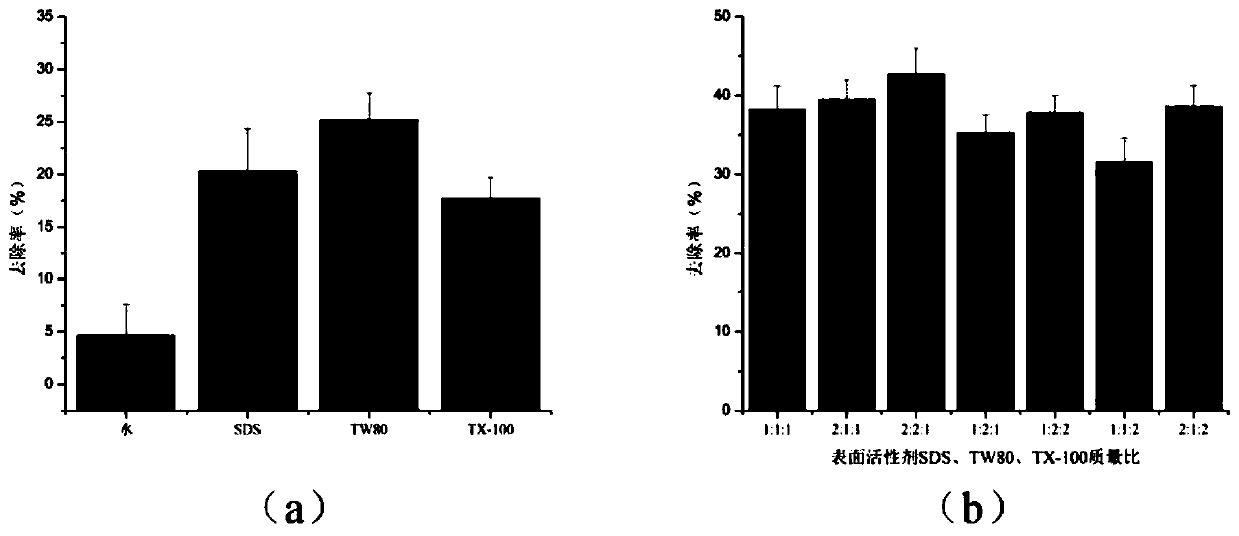

[0045] Pulverize the oil-contaminated soil, remove impurities, dry it outdoors for 8 hours, store it in a square shallow dish, add a cleaning solution, (the cleaning solution is a cleaning solution, a single-surfactant cleaning solution or a mixed-surfactant cleaning solution), and place the shallow dish in the Stir at room temperature for 24h under agitator, let it settle naturally after mixing, discard the liquid phase, take out the solid phase and air-dry in a dark and ventilated place, seal the shallow dish for later use, and measure the content of petroleum hydrocarbons in the soil (see figure 2 ).

[0046] Among them, the final concentration of surfactant in the washing solution is 3g / L, the final concentration of auxiliary agent is 5g / L, the mass ratio of surfactant is SDS:TW-80:TX-100=2:2:1, and the mass of auxiliary agent is The ratio of sodium lignosulf...

Embodiment 3

[0052] The bacterial liquid obtained in the step (2) of the above embodiment 1, the biochar obtained in the step (1), and the immobilized microbial material obtained above at a pyrolysis temperature of 500 ° C are respectively mixed with the contaminated soil, degraded, and the content of petroleum hydrocarbons in the soil is determined, ( see Figure 4 )

[0053] At the same time, the above-mentioned immobilized microbial material obtained at a pyrolysis temperature of 500 ° C was added to the oil-contaminated soil after washing with the cleaning solution, and then water was added to make the soil moisture content reach 25%, an appropriate amount of normal soil and wood chips were added, and the mixture was fully stirred. The shallow dish is placed under natural conditions, the temperature is 20-26 ℃, and the water is regularly replenished, turned evenly, and NH4Cl and K2HPO4 are added to make the N and P concentrations in the soil reach 2000 mg / kg and 200 mg / kg respectively;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com