Surface acoustic wave device based on hafnium ferroelectric film and film bulk acoustic wave device

A surface acoustic wave device and thin-film bulk acoustic wave technology, which is applied in the electronic field, can solve the problems of CMOS process compatibility, chip system integration, space occupation, etc., and achieve the effects of reducing signal transmission distance, reducing equipment volume, and improving portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

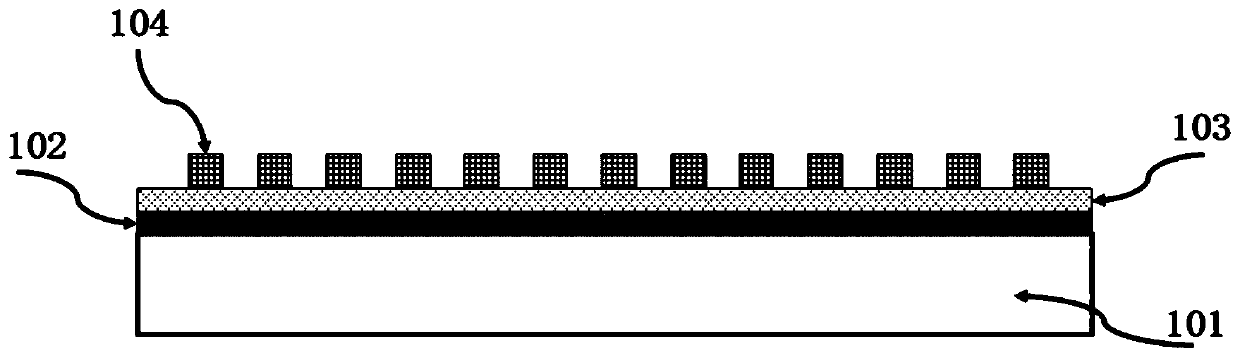

[0030] In this embodiment, a single-port resonant surface acoustic wave device based on hafnium-based ferroelectric thin films is proposed, which has signal processing functions, and its cross-sectional structure is as follows figure 1 As shown, it includes a bottom electrode layer 102, a piezoelectric layer 103 and a top electrode layer 104 sequentially stacked on a substrate 101; the piezoelectric layer 103 of this embodiment adopts a hafnium-based ferroelectric thin film doped with zirconium, and the top electrode layer 104 is a plurality of interdigital electrodes arranged in sequence, and the corresponding interdigital electrodes respectively form an interdigital transducer and a reflective grid array.

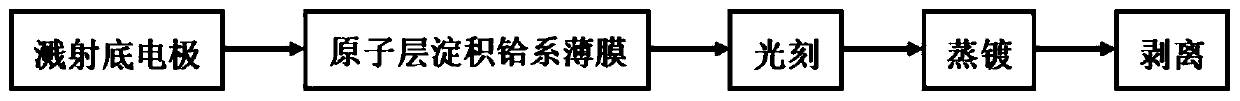

[0031] The preparation process of the surface acoustic wave device in this embodiment is as follows: figure 2 As mentioned, the specific process is as follows:

[0032] Firstly, a layer of titanium nitride bottom electrode layer 102 is sputtered on the substrate 101 by ...

Embodiment 2

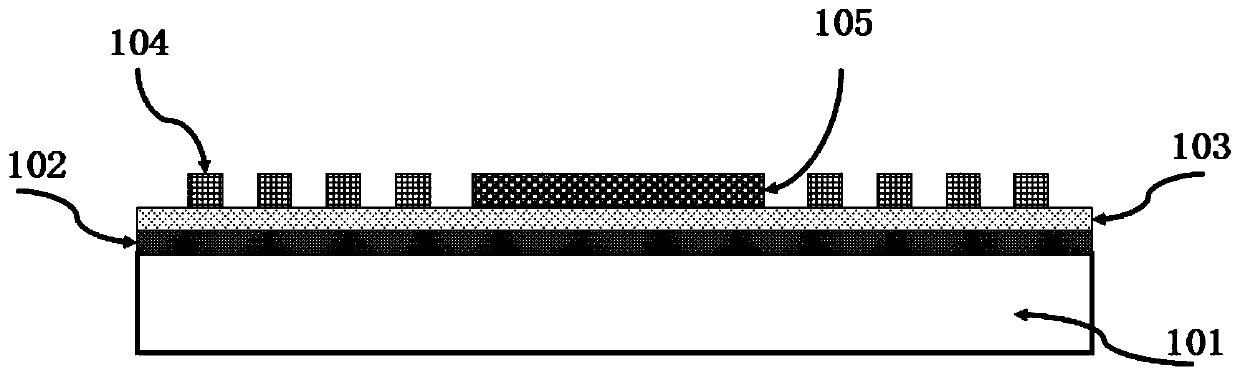

[0034] In this embodiment, a surface acoustic wave device based on a hafnium-based ferroelectric thin film is proposed, which is a delay line type and is mainly used to realize the sensing function. Its cross-sectional structure is as follows image 3As shown, it includes a bottom electrode layer 102, a piezoelectric layer 103 and a top electrode layer 104 stacked sequentially on a substrate 101, and the surface of the piezoelectric layer 103 between the top electrode layers 104 is also coated by drop coating, spin coating, electrostatic Spraying, chemical solution growth, or inkjet printing are provided with a sensitive film 105 for sensing the environment. The sensitive film detects environmental parameters corresponding to the substance by adsorbing related substances in the environment. The piezoelectric layer 103 of this embodiment adopts a hafnium-based ferroelectric film doped with silicon, and the doping concentration of silicon is 4%; the top electrode layer 104 is inp...

Embodiment 3

[0039] In this embodiment, an example of integrating a surface acoustic wave resonator, a sensor, and a ferroelectric storage unit to obtain device integration is proposed, such as Figure 4 As shown, it includes a surface acoustic wave resonator 201, a surface acoustic wave sensor 202, a ferroelectric storage unit (which may be a ferroelectric capacitor) 203 and six MOS field effect transistors (204-206, 208-210). The surface acoustic wave resonator 201 and the surface acoustic wave sensor 202 of the present embodiment can be obtained by the method in embodiment 1 and 2, an interdigital transducer in the surface acoustic wave resonator 201 has two lead-out ends, and the surface acoustic wave Each interdigital transducer in the wave sensor 202 jointly forms two lead-out ends. The ferroelectric capacitor 203 is used for storage function, and its structure is as follows Figure 5 As shown, it includes a bottom electrode layer 302, a ferroelectric thin film 303 and a top electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com