A kind of preparation method of porous boron nitride-based composite material for organic wastewater purification

A composite material, organic wastewater technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of hindering the practical application of porous boron nitride, secondary environmental pollution, high energy consumption, and improve regeneration and reuse. performance, reduced regeneration costs, and the effect of a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

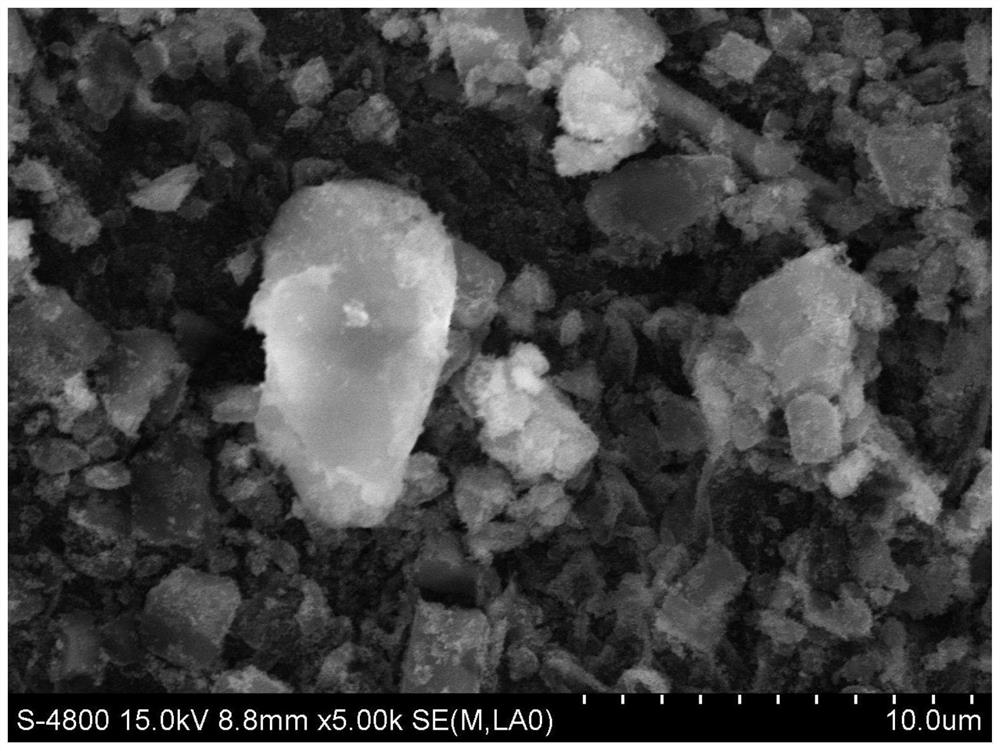

[0024] see Figure 1-4 , (1) Weigh porous boron nitride and ferric chloride with a mass ratio of 1:0.01, place them in deionized water, stir for 0.5 hours, and then sonicate for 0.1 hours;

[0025] (2) Adjust the pH value of the mixed solution obtained in step (1) to 9, and stir for 0.5 hours;

[0026] (3) Place the mixed solution obtained in step (2) in an autoclave, and heat it to 140° C. under the assistance of microwaves, and keep it warm for 0.1 hour;

[0027] (4) After the mixed solution obtained in step (3) is cooled to room temperature, the solid powder is obtained by filtration, and the gained solid powder is placed in a ball mill jar of a ball mill, and the ball mill is milled for 10 minutes at a speed of 100 revolutions per minute;

[0028] (5) The solid mixture obtained in step (4) was heat-treated at 600° C. in an ammonia atmosphere with a flow rate of 10 ml / min, the heating rate was 1° C. per minute, and the holding time was 3 hours. The resulting product is a ...

Embodiment 2、 example 3

[0031] Change the mass ratio of porous boron nitride and ferric chloride in step (1) in Example 1 to 1:1, 1:100, and other operations are the same as in Example 1, and the product obtained is the same as in Example 1 .

Embodiment 4、 example 5

[0033] Change the stirring time in step (1) in embodiment 1 to 1 hour, 2 hours, other each operation is all identical with embodiment 1, obtains product with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com