Polyvinyl chloride elastomer containing fumed silica

A technology of fumed silica and polyvinyl chloride, used in the field of wire and cable materials, can solve the problems of poor lasting stability, destruction of material stability, mutual influence of sensitive reagents, etc., and achieve good thermal stability and strong industrial application value. And development prospects, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

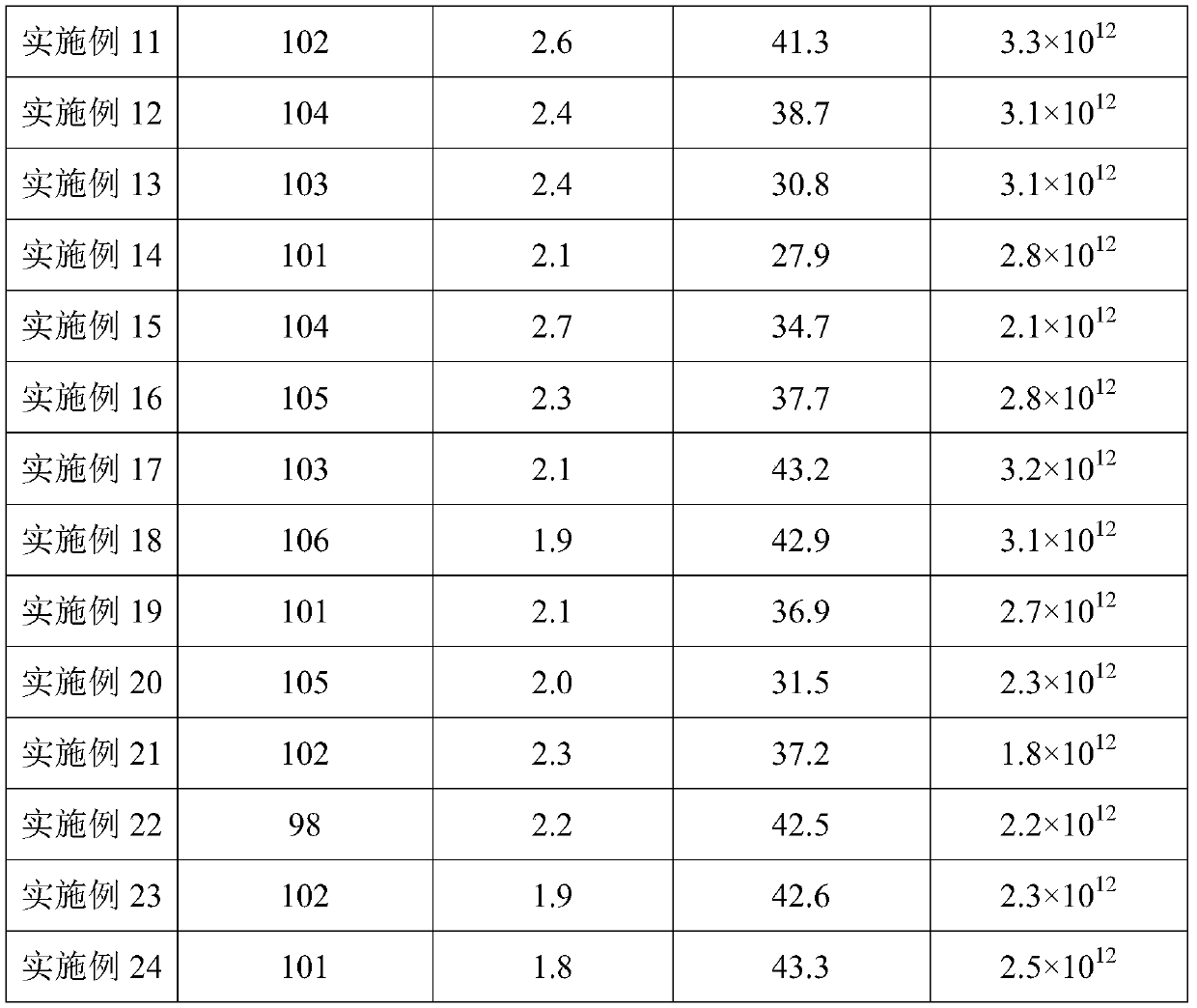

Examples

preparation example Construction

[0122] The second aspect of the present invention provides a kind of preparation method of polyvinyl chloride elastomer, comprises the steps:

[0123] (1) Add polyvinyl chloride, nitrile rubber, fumed silica, nano-titanium dioxide, plasticizer, flame retardant, antistatic agent, and foaming agent to the high-speed mixer in sequence at 800-900rpm Mix evenly at a stirring speed of 100°C, heat up to 80-100°C and continue stirring for 15-25 minutes to obtain mixture A;

[0124](2) Cool the mixture A prepared in step (1) to 70-80° C. at a stirring speed of 500-600 rpm to obtain mixture B;

[0125] (3) Add the mixture B prepared in step (2) into an extruder, extrude and granulate to obtain a polyvinyl chloride elastomer.

[0126] In a preferred embodiment, the preparation method of the polyvinyl chloride elastomer is as follows:

[0127] (1) Add polyvinyl chloride, nitrile rubber, fumed silica, nano-titanium dioxide, plasticizer, flame retardant, antistatic agent, and foaming agen...

Embodiment 1

[0133] Embodiment 1 of the present invention provides a polyvinyl chloride elastomer, in parts by mass, the polyvinyl chloride elastomer comprises 70 parts of polyvinyl chloride, 25 parts of nitrile rubber, 18 parts of filler, 8 parts of plasticizer, 2 parts of flame retardant, 1.5 parts of antistatic agent, 0.8 parts of foaming agent.

[0134] Described nitrile rubber is the nitrile rubber that acrylonitrile mass content is 34%;

[0135] The filler is 12.5 parts of modified fumed silica with a particle diameter of 30nm and 5.5 parts of nano titanium dioxide with a particle diameter of 15nm;

[0136] What described plasticizer selects for use is dioctyl phthalate;

[0137] What described flame retardant selected for use is tricresyl phosphate;

[0138] What described antistatic agent selects for use is the polyethylene glycol that relative molecular weight is 600;

[0139] What described foaming agent selects for use is fatty alcohol polyoxyethylene ether sodium sulfate;

...

Embodiment 2

[0150] Embodiment 2 of the present invention provides a polyvinyl chloride elastomer. In parts by mass, the polyvinyl chloride elastomer includes 65 parts of polyvinyl chloride, 20 parts of nitrile rubber, 14 parts of filler, 6 parts of plasticizer, 1 part of flame retardant, 1 part of antistatic agent, 0.6 part of foaming agent.

[0151] Described nitrile rubber is the nitrile rubber that acrylonitrile mass content is 34%;

[0152] The filler is 10 parts of modified fumed silica with a particle size of 30nm and 4 parts of nano-titanium dioxide with a particle size of 15nm;

[0153] What described plasticizer selects for use is dioctyl phthalate;

[0154] What described flame retardant selected for use is tricresyl phosphate;

[0155] What described antistatic agent selects for use is the polyethylene glycol that relative molecular weight is 600;

[0156] What described foaming agent selects for use is fatty alcohol polyoxyethylene ether sodium sulfate;

[0157] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com