Catalyst for preparing C4-C8 higher alcohols by ethanol conversion and its preparation method and application

A high-carbon alcohol and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, can solve the problem of affecting the continuous production of butanol and affecting the selectivity of butanol and other problems, to achieve good economy and practicability, easy control of components, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

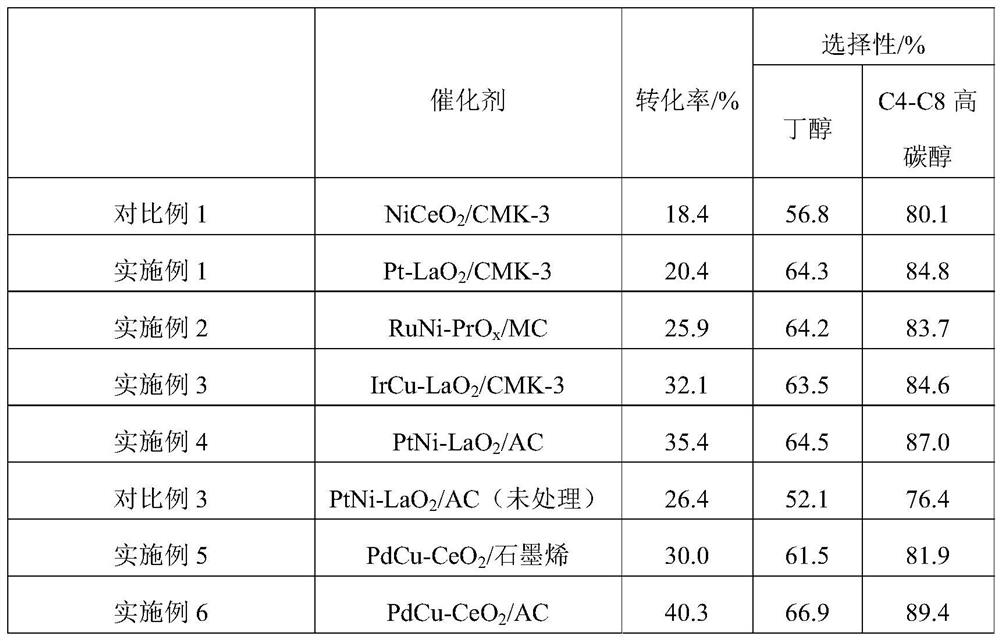

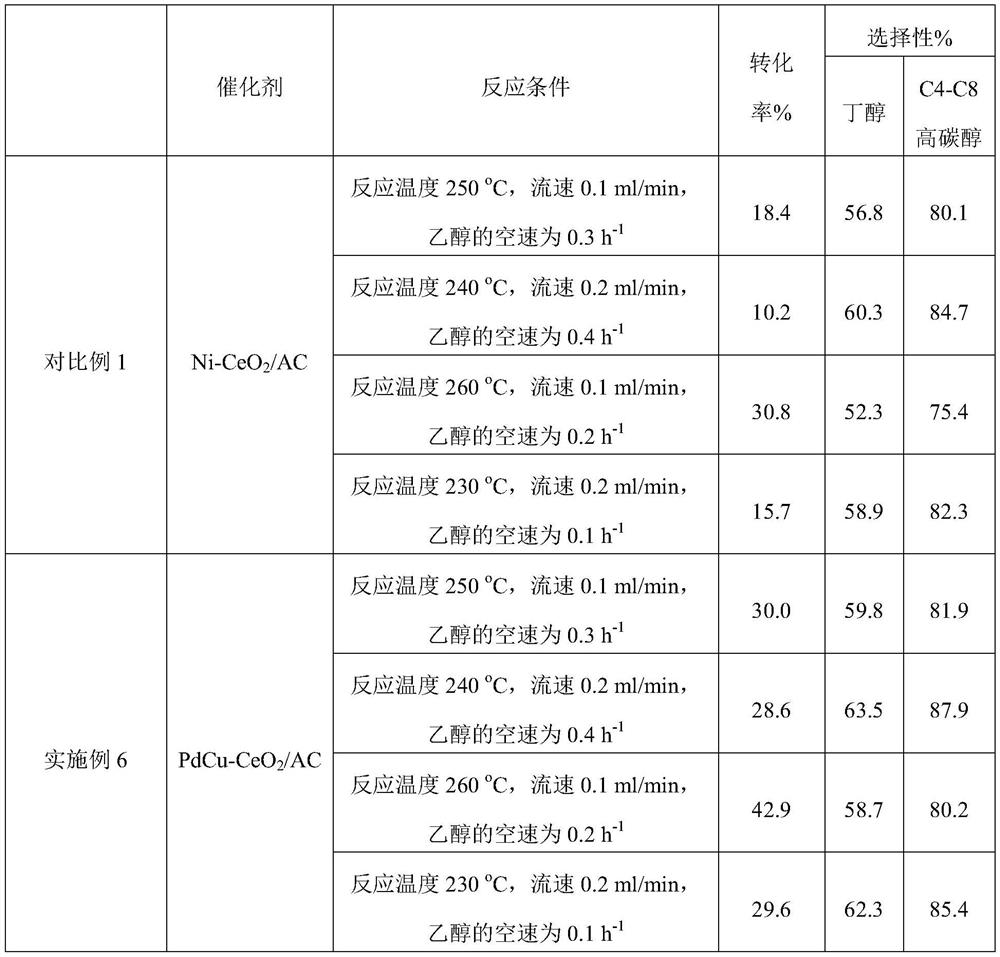

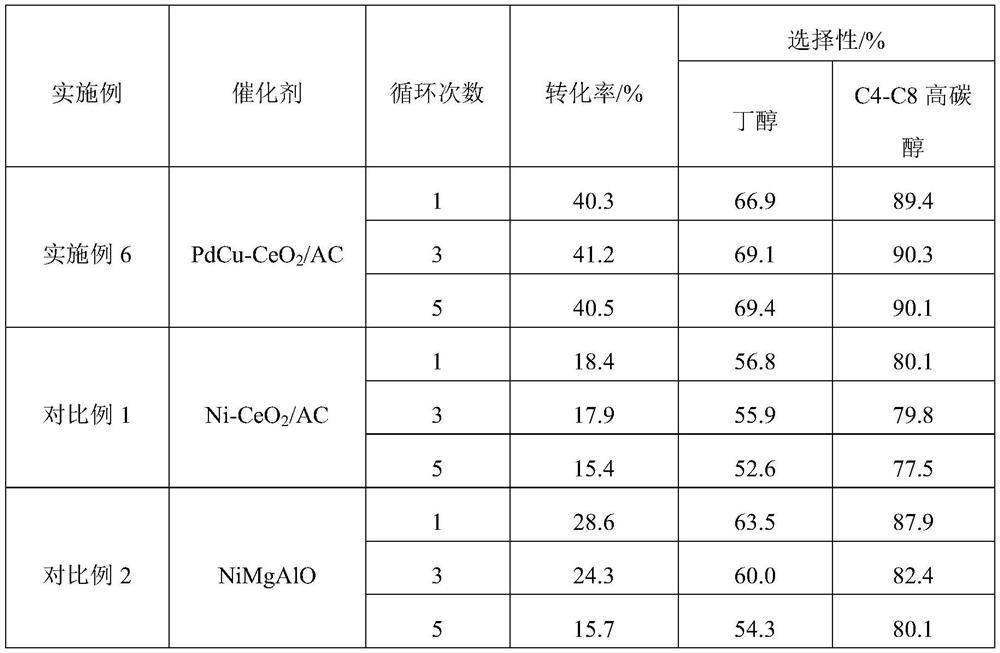

Examples

Embodiment 1

[0047] Pt-LaO 2 Preparation of / CMK-3 catalyst:

[0048] The acid treatment of CMK-3 is the same as in Comparative Example 1.

[0049] Weighed 0.47g of lanthanum nitrate, dissolved in 10mL of deionized water, added 1g of CMK-3 into the above salt solution under stirring, immersed for 6 hours, dried by rotary evaporation, and roasted at 300°C for 2 hours under nitrogen atmosphere. Dissolve 1 ml of 2% Pt chloride or nitrate solution in 20 ml of water (acid can be added to prevent precipitation), and LaO 2 / CMK-3 was added to the above solution, stirred well, then added ammonia solution to adjust the pH to 10, aged for 2 hours, filtered and dried. After drying, the sample was reduced by hydrazine hydrate for 2h to obtain the final 2%Pt-15%LaO 2 / CMK-3 catalyst.

Embodiment 2

[0051] RuNi-PrO 2 Preparation of / MC catalyst:

[0052] The pretreatment condition of MC is the same as that of Comparative Example 1, and the oxygen content of MC after treatment is 1.6%.

[0053] Weighed 0.49g of praseodymium nitrate, 0.1g of nickel nitrate and 1ml of 2% ruthenium chloride solution were dissolved in 10mL of deionized water. Add 1g of mesoporous carbon MC into the above salt solution under stirring, stir for 4 hours, let stand overnight, dry at 120°C for 5 hours, and reduce at 350°C for 1 hour under a hydrogen atmosphere to finally obtain 2%Ru2%Ni-20%PrO x / MC Catalyst.

Embodiment 3

[0055] IrCu-LaO 2 Preparation of / CMK-3 catalyst:

[0056] The acid treatment of CMK-3 is the same as in Comparative Example 1.

[0057] Firstly, LaO was prepared by impregnation method 2 / CMK-3 catalyst, and then adopt the adsorption method to prepare the supported IrCu catalyst, the specific process is: weighed 0.47g lanthanum nitrate, dissolve it in 10mL deionized water, add 1g CMK-3 in the above-mentioned salt solution under stirring, impregnate 6 hours, dry by rotary evaporation, and bake at 300° C. for 2 hours under nitrogen atmosphere. Dissolve 2 milliliters of 0.5% Ir chloride solution in 20 mL water and 0.1 g nickel nitrate (acid can be added to prevent precipitation), and LaO 2 / CMK-3 was added to the above solution, stirred thoroughly for 5 hours, and dried by filtration. After drying, the sample was reduced by ethylene glycol at 200°C for 4 hours to obtain the final 1%Ir2%Ni-15%LaO 2 / CMK-3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com