Method for preparing single-layer cholesteric liquid crystal film through elution/refilling technology and application of single-layer cholesteric liquid crystal film

A cholesteric liquid crystal, refilling technology, applied in the directions of instruments, optics, optical components, etc., can solve the problems of affecting the transmittance of the system, narrow reflection bandwidth, single-layer cholesteric liquid crystal film, etc., to avoid adverse effects. , the production process is simple, the effect of rich material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Fabrication of the liquid crystal cell: place the cleaned indium tin oxide (ITO) glass in a drying oven at 60° C. for 3 hours to dry. Add 3 g of polyvinyl alcohol (PVA) white solid particles into 97 mL of deionized water, stir magnetically, and slowly heat to 90° C. until all of them dissolve to obtain a 3% PVA solution. Use a homogenizer to coat the ITO glass with an initial speed of 600r / min for 10s and a high speed of 2000r / min for 30s, then heat-treat the glass substrate coated with the PVA polymer film at a temperature of 90°C for 120min. Use a flannel cloth to perform 3 times of directional rubbing on the side coated with the PVA orientation layer, avoiding excessive force as much as possible. The above two glass substrates were combined, the rubbing direction was antiparallel, and a PET film with a thickness of 50 μm was used as a spacer to make a liquid crystal cell.

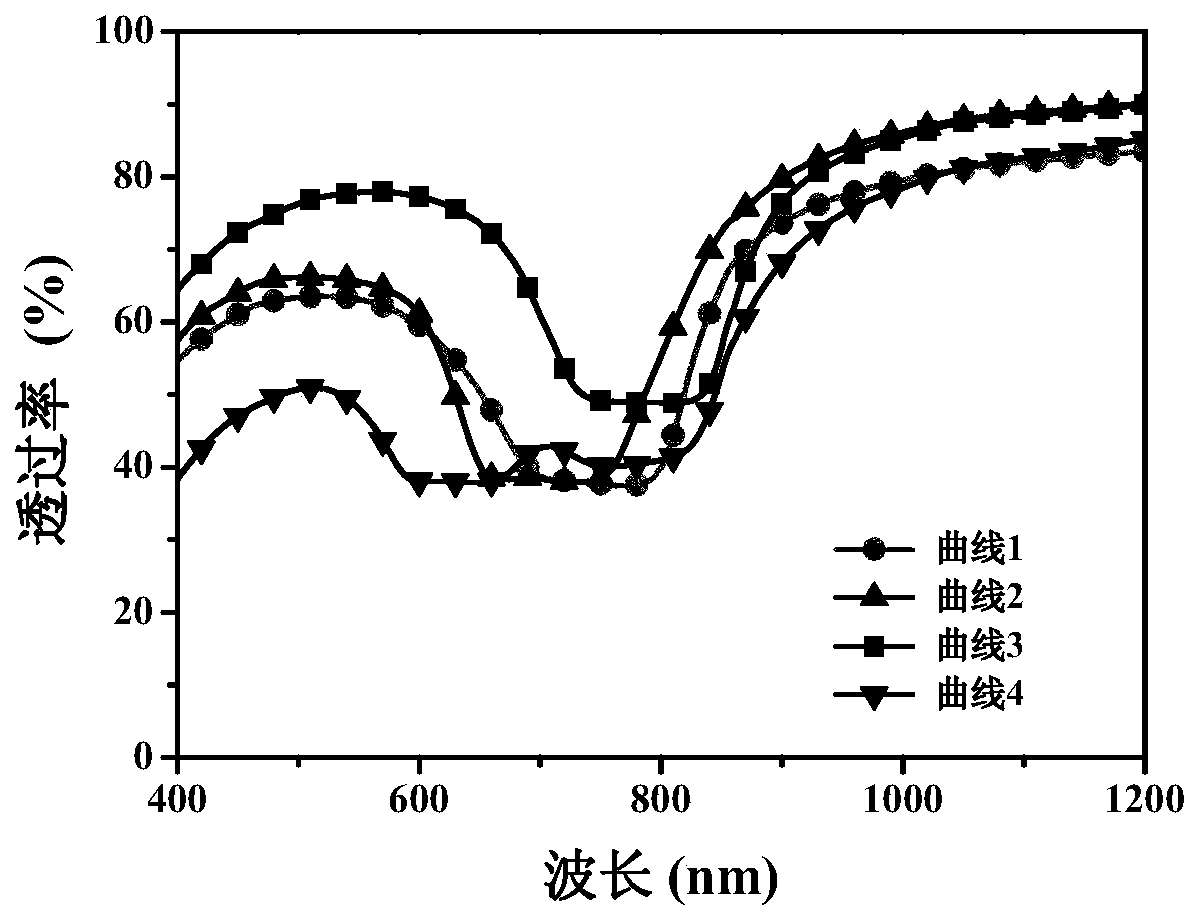

[0038] Mix the nematic liquid crystal SLC1717, the chiral compound R5011, the polymerizable m...

Embodiment 2

[0052] Nematic liquid crystal E7, chiral compound S811, polymerizable monomer RM257 and photoinitiator 184 were uniformly mixed in a mass ratio of 54:25:20:1, and poured into a plane-aligned liquid crystal cell at room temperature.

[0053] S811 chemical structural formula:

[0054]

[0055] RM257 chemical structural formula:

[0056]

[0057] Photoinitiator 184 chemical structural formula:

[0058]

[0059] After the system is stable, use 365nm ultraviolet light to irradiate the liquid crystal cell, and the ultraviolet irradiance is 4mW / cm 2 , the irradiation time is 20 minutes, so that the polymerizable monomers are cured and cross-linked to form a network.

[0060] Soak the polymerized sample in a mixture of acetone and chloroform to submerge the liquid crystal cell, store it for 5 days, take it out, place it in a drying oven at 60°C for 4 hours, and obtain a liquid crystal cell containing a polymer network.

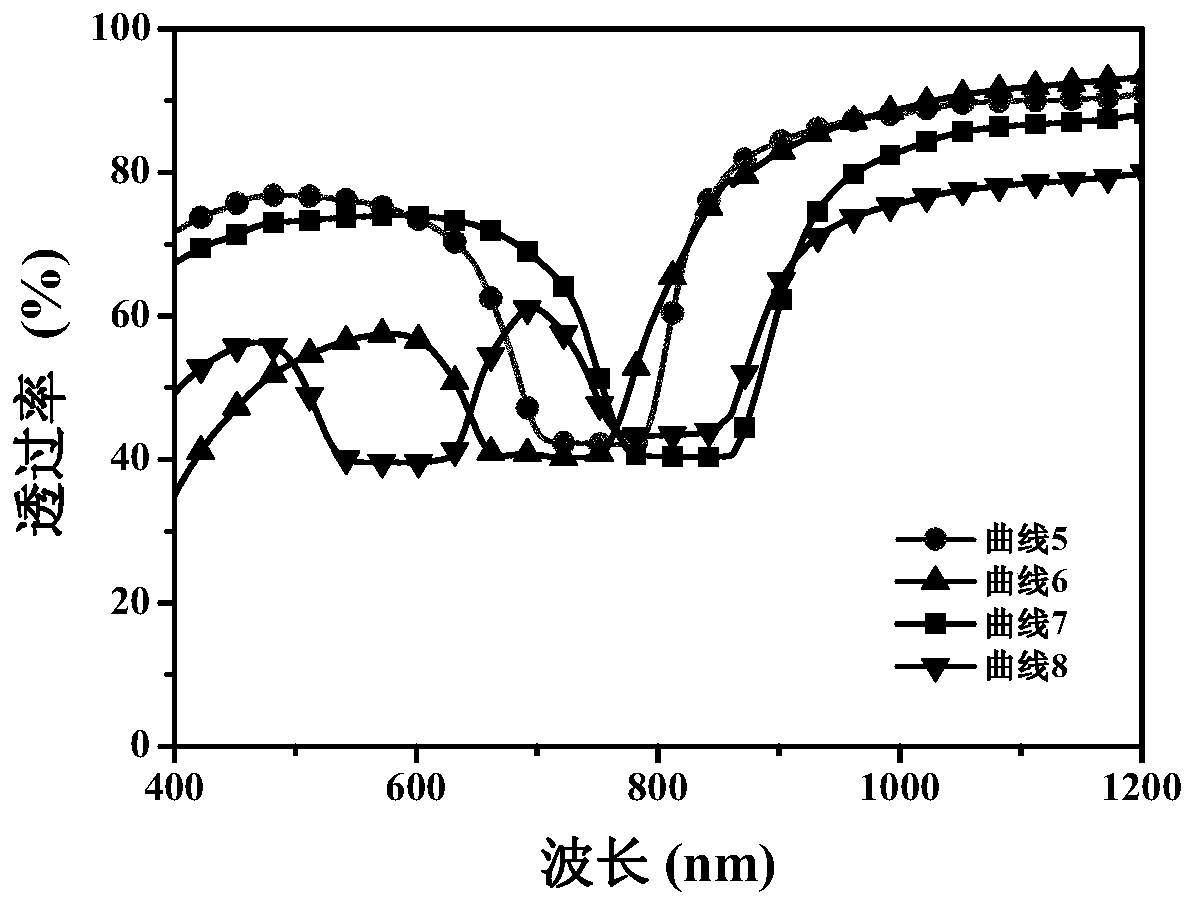

[0061] Mix nematic liquid crystal E7, chiral compoun...

Embodiment 3

[0063] Nematic liquid crystal SLC7011, chiral compound R1011, polymerizable monomer LC242 and photoinitiator 907 were mixed evenly at a mass ratio of 73:8:18:1, and poured into a plane-oriented liquid crystal cell at room temperature.

[0064] Chemical structural formula of R1011:

[0065]

[0066] LC242 chemical structural formula:

[0067]

[0068] Chemical structural formula of photoinitiator 907:

[0069]

[0070] After the system is stable, use 365nm ultraviolet light to irradiate the liquid crystal cell, and the ultraviolet light irradiance is 5mW / cm 2 , the irradiation time is 20 minutes, so that the polymerizable monomers are cured and cross-linked to form a network.

[0071] Soak the polymerized sample in cyclohexane to submerge the liquid crystal cell, store it for 5 days, take it out, place it in a drying oven at 60°C for 6 hours, and obtain a liquid crystal cell containing a polymer network.

[0072] Mix nematic liquid crystal SLC7011, chiral compound R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com