Lubricating grease for robot and application of lubricating grease

A robot and grease technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of poor extreme pressure and anti-wear, low temperature grease resistance, poor mechanical stability, etc., to reduce friction coefficient, excellent lubrication effect, excellent The effect of load-carrying capacity and anti-friction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

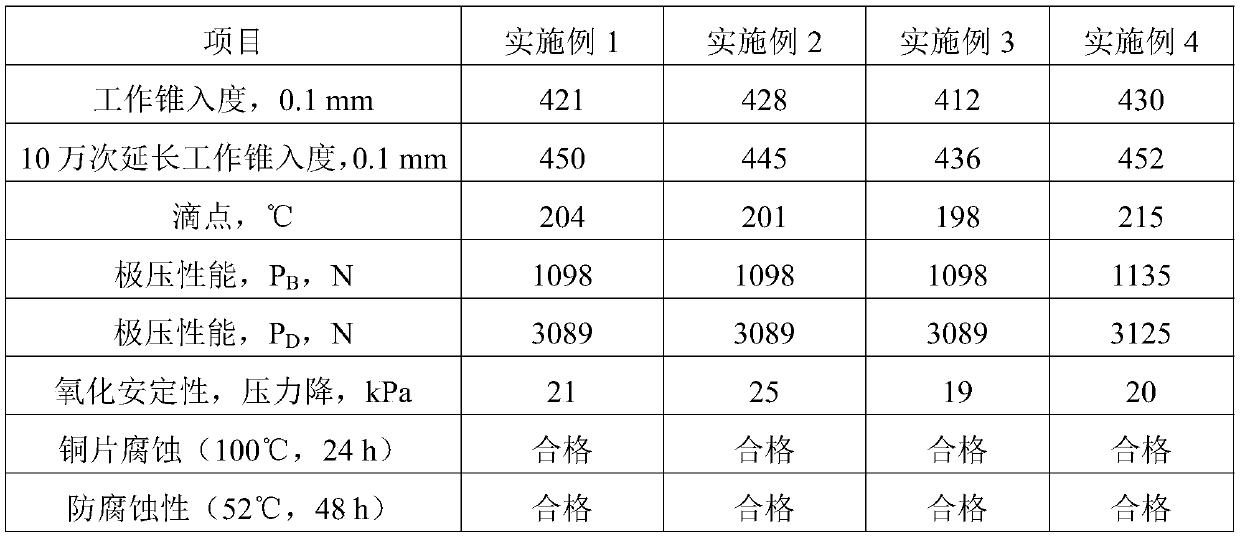

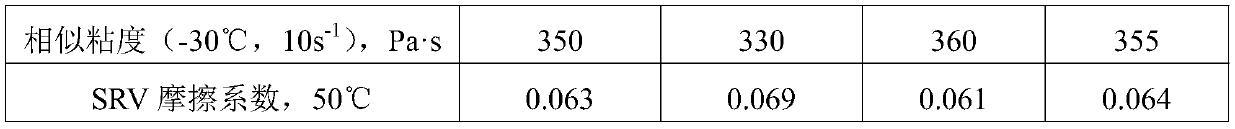

Embodiment 1

[0027] The present embodiment provides a kind of lubricating grease for robots, comprising the following components: in terms of mass fraction, 80% of base oil, 5% of lithium complex soap thickener, antioxidant (mass ratio is 1:1.3 diphenylamine and 2 , 6-di-tert-butyl p-cresol) 3%, extreme pressure antiwear agent (thiadiazole derivatives, molybdenum phosphate and triphenyl phosphate with a mass ratio of 3:25:5) 3%, solid lubricant ( α-zirconium phosphate) 2% and complex calcium sulfonate base grease 7%; the base oil is a mixture of hydrogenated base oil, PAO8 and diisobutyl phthalate in a mass ratio of 1:3:1.

[0028] Mix the hydrorefined base oil, PAO8 and methyl phthalate evenly and add it to the complex lithium soap, then add the antioxidant, extreme pressure anti-wear agent, solid lubricant, and calcium sulfonate complex grease respectively. Grinding and dispersing with a three-roll mill to obtain finished grease.

Embodiment 2

[0030] The present embodiment provides a kind of lubricating grease for robots, comprising the following components: in mass fraction, base oil 85.7%, lithium complex soap thickener 6%, antioxidant (mass ratio is 1:1 diphenylamine and 2 , 6-di-tert-butyl p-cresol) 1%, extreme pressure antiwear agent (thiadiazole derivatives, molybdenum phosphate and triphenyl phosphate with a mass ratio of 1:3:2) 2.3%, solid lubricant ( gamma-zirconium phosphate) 1% and complex calcium sulfonate base grease 4%; the base oil is hydrorefined base oil, PAO10 and triisotridecyl trimellitate ( TMTT) mixture.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] The present embodiment provides a kind of lubricating grease for robots, comprising the following components: in mass fraction, base oil 78%, lithium complex soap thickener 6%, antioxidant (mass ratio is 1:2 diphenylamine and 2 , 6-di-tert-butyl p-cresol) 2%, extreme pressure antiwear agent (thiadiazole derivatives, molybdenum phosphate and triphenyl phosphate with a mass ratio of 1:5:2) 4%, solid lubricant ( τ-zirconium phosphate) 2.5% and complex calcium sulfonate base grease 7.5%; the base oil is a mixture of hydrorefined base oil, PAO10 and triethylol propane ester with a mass ratio of 3:3:1.

[0034] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com