Glass fiber powder/polypyrrole/Ti<3>C<2>T<x>MXene ternary composite filler, and preparation method and application thereof

A technology of glass fiber powder and three-component compounding, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve good film-forming properties, simple preparation process, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In parts by weight, put 15 parts of glass fiber powder into a beaker, add 50 mL of 10% nitric acid solution, heat and stir for 30 min, and centrifugally dry to remove impurities in the glass fiber powder. Add the obtained powder to 50mL piranha solution in an ice-water bath, and after the system is stable, heat and boil for 30 minutes, and then centrifugally dry to obtain hydroxylated glass fiber powder. In the mixed solution of V (ethanol: aqueous solution) at 9:1, add KH550 coupling agent with a solvent mass of 2%, stir for 30 minutes, and then add hydroxylated glass fiber powder to the solution. Heat and stir at 70°C for 3 hours, then stir at room temperature for 24 hours to obtain glass fiber powder of grafted coupling agent.

[0037] Weigh 100 parts of E44 type epoxy resin, 13.3 parts of glass fiber powder obtained after treatment, and add it into 33 parts of xylene-n-butanol solvent (xylene:n-butanol=4:1). After stirring evenly, add 23.3 parts of T31 curing agent. ...

Embodiment 2

[0039] Weigh 100 parts of E44 type epoxy resin and 3.3 parts of polypyrrole, and add them into 33 parts of xylene-n-butanol solvent (xylene:n-butanol=4:1). After stirring evenly, add 23.3 parts of T31 curing agent. After continuing to stir, the obtained coating was coated on the polished tinplate to obtain the prepared coating, and its electrochemical performance was measured.

Embodiment 3

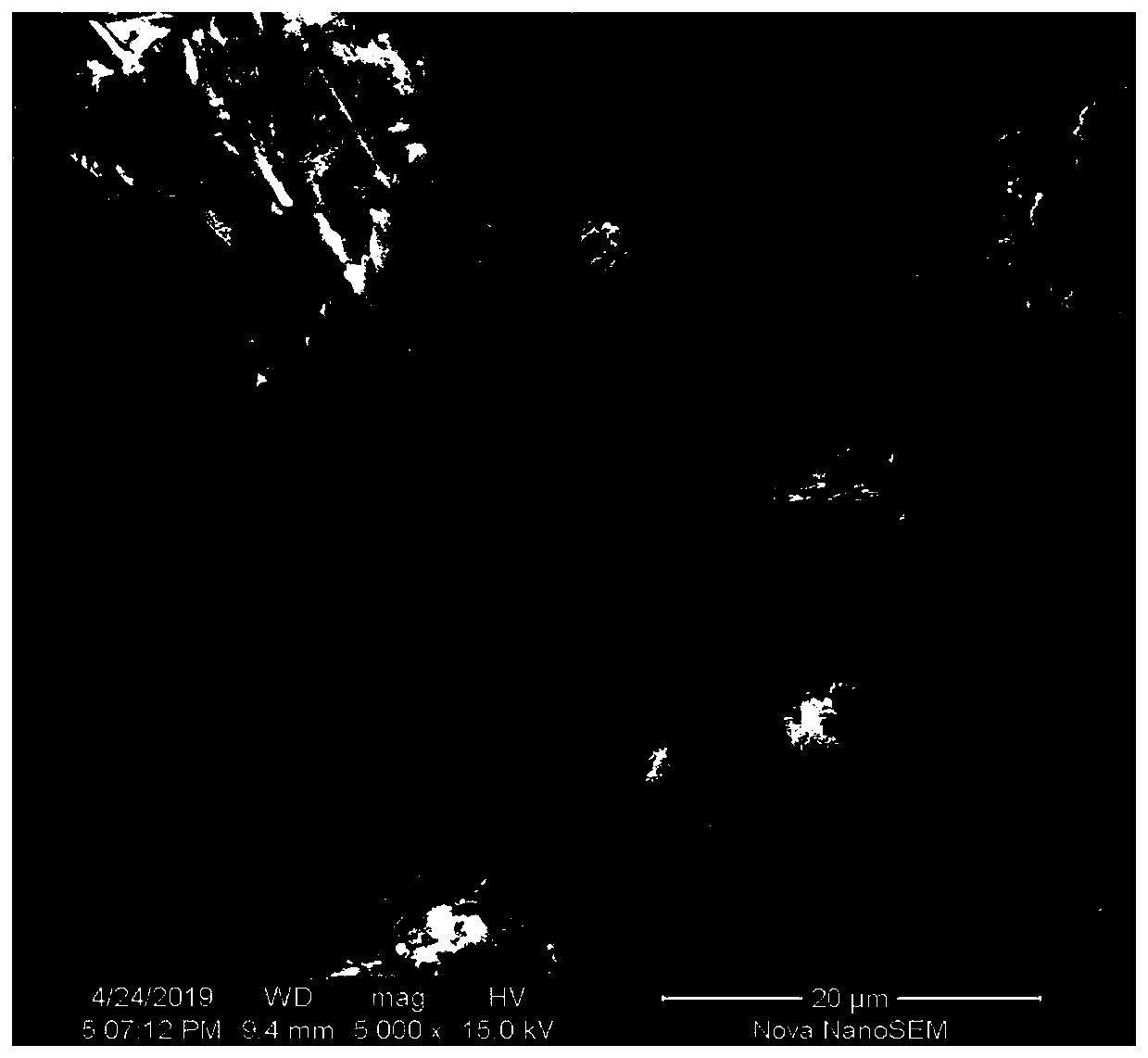

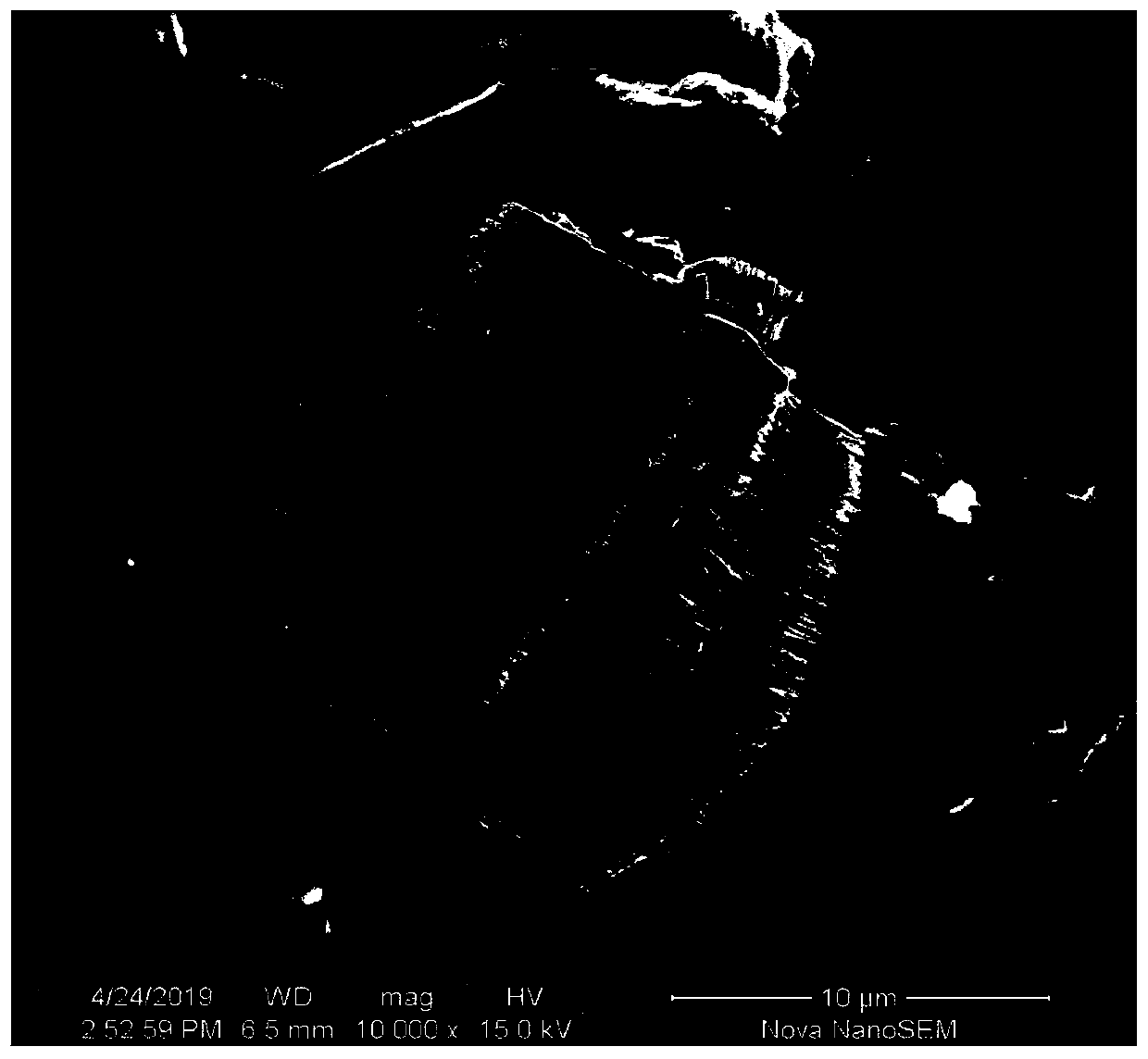

[0041] According to the method of Example 1, 15 parts of graft coupling agent glass fiber powder were prepared, added to 1M HCl solution, ultrasonically dispersed for 30 minutes, 13 μL of pyrrole monomer was added to the mixed system, and stirred in an ice-water bath for 1 hour. Finally, 1.3 parts of ammonium persulfate solution was added dropwise, stirred in an ice-water bath for 12 hours, centrifuged, and vacuum-dried to obtain a glass fiber powder / polypyrrole composite material. The obtained composites were examined by scanning electron microscopy as figure 2 As shown, it can be seen that glass fiber powder and polypyrrole have been compounded in the figure.

[0042] Slowly add 5 parts of LiF to the hydrochloric acid solution, stir until the white LiF is completely dissolved, then slowly add 4 parts of Ti 3 AlC 2 MAX phase, stirred in a water bath at 35°C for 24 hours, the resulting liquid is the etched Ti 3 C 2 T x MXene solution; after 800W ultrasonic dispersion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com