Bionic synaptic device, manufacturing method and application thereof

A synaptic device and synaptic technology, applied in the direction of electrical components, etc., can solve the problems of high working voltage, lack of dynamic learning and memory ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

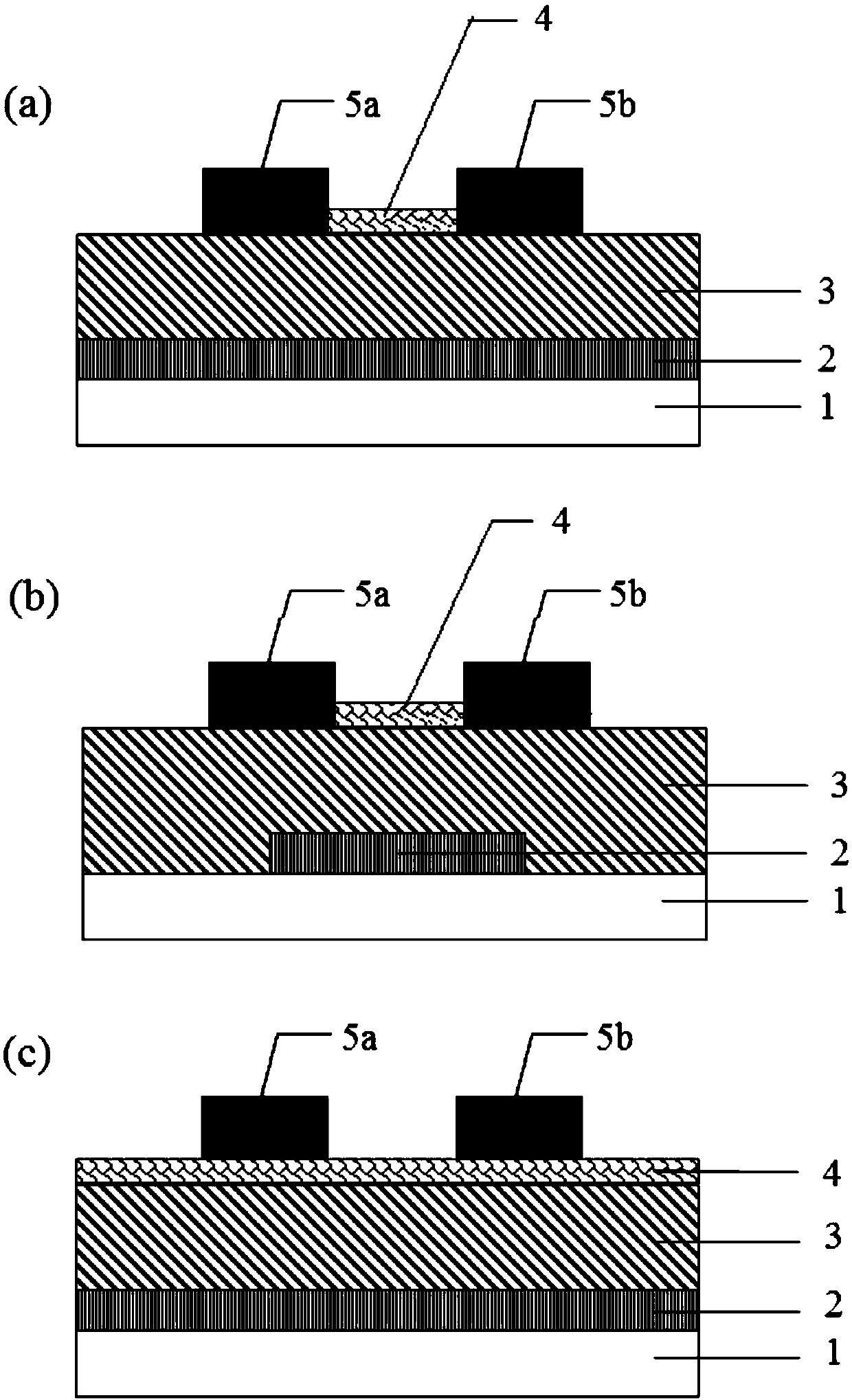

[0180] In this example, if figure 1 As shown in (a), glass substrate is selected as insulating substrate 1, indium tin oxide film (InSnO) is selected as conductive layer 2, chitosan film is selected as gate dielectric layer 3, and indium tin oxide film (InSnO) is selected as channel layer 4. ).

[0181] The manufacturing method of the oxide biomimetic synapse device comprises the following steps:

[0182] Step 1: Clean the glass substrate sequentially with alcohol and deionized water ultrasonically and dry it with a nitrogen gun, then deposit an InSnO thin film conductive layer 2 on the surface of the glass substrate 1;

[0183] Step 2: On the conductive layer 2, prepare a chitosan film 3 by spin coating, and the thickness of the chitosan grid dielectric film is 12 microns;

[0184] Step 3: On the chitosan film 3, use magnetron sputtering technology to deposit patterned InSnO channel layer 4, and form patterned InSnO source and drain electrodes 5a and 5b on both sides of th...

Embodiment 2

[0187] In this example, if figure 1 As shown in (b), a plastic substrate is selected for the insulating substrate 1, an indium zinc oxide film (InZnO) is selected for the conductive layer 2, a porous silicon dioxide film is selected for the gate dielectric layer 3, and an indium zinc oxide film (InZnO) is selected for the channel layer 4 ( InZnO).

[0188] The manufacturing method of the oxide biomimetic synapse device comprises the following steps:

[0189] Step 1: ultrasonically clean the plastic substrate with alcohol and deionized water in sequence and dry it with a nitrogen gun, and then deposit a patterned InZnO thin film conductive layer 2 on the surface of the plastic substrate 6;

[0190] Step 2: On the conductive layer 2, a porous silicon dioxide particle gate dielectric film 3 is deposited by plasma-enhanced chemical vapor deposition (PECVD), and the thickness of the porous silicon dioxide particle film is 2 microns;

[0191] Step 3: On the porous silicon dioxide...

Embodiment 3

[0194] In this example, if figure 1 As shown in (c), polyimide substrate is selected for insulating substrate 1, aluminum zinc oxide film (AZO) is selected for conductive layer 2, sodium alginate film is selected for gate dielectric layer 3, and indium tungsten oxide is selected for channel layer 4 thin film (InWO).

[0195] The manufacturing method of the oxide biomimetic synapse device comprises the following steps:

[0196] Step 1: ultrasonically clean the polyimide substrate with alcohol and deionized water in sequence and dry it with a nitrogen gun, and then deposit an aluminum zinc oxide film (AZO) conductive layer 2 on the surface of the polyimide substrate 1;

[0197] Step 2: On the conductive layer 2, prepare a sodium alginate film 3 by spin coating, the thickness of the sodium alginate film is 8 microns, as a gate dielectric layer;

[0198] Step 3: On the sodium alginate gate dielectric film 3, deposit an indium tungsten oxide film (InWO) as a channel layer 4 by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com